High-efficient crushing device for petroleum coke

A crushing device and petroleum coke technology, applied in grain processing, etc., can solve problems such as inconvenient use, complicated operation, and low work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

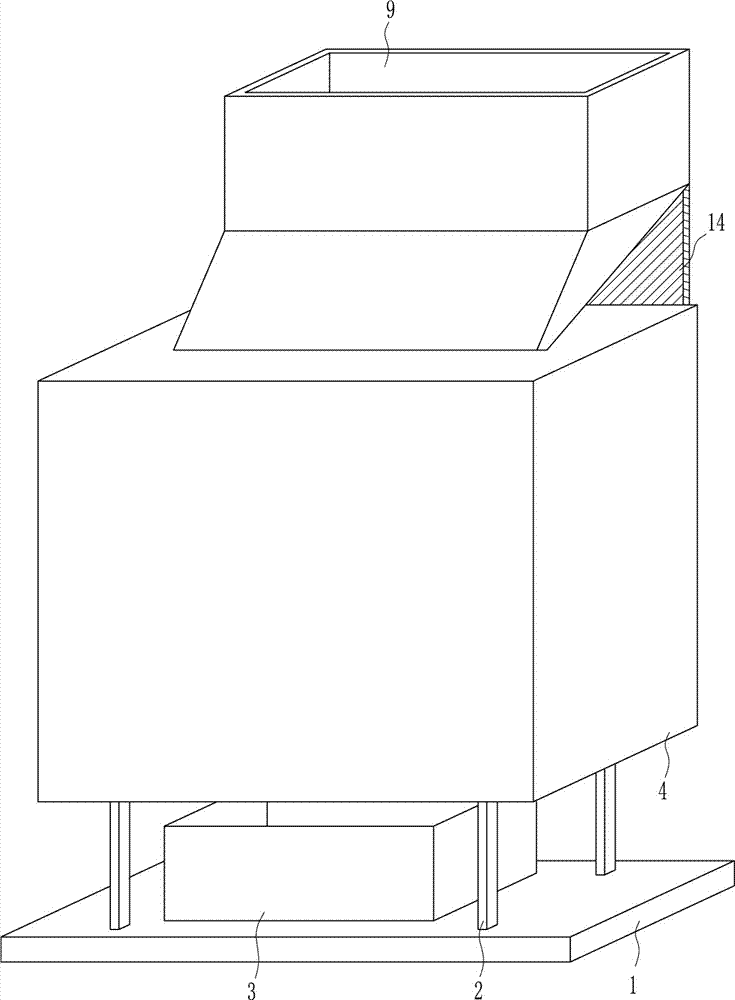

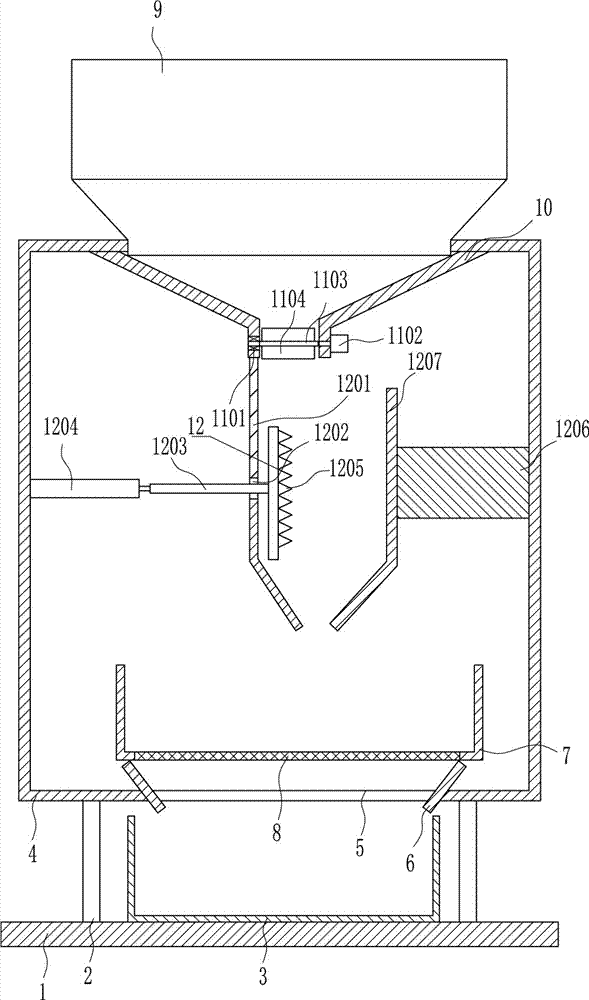

[0036] A high-efficiency crushing device for petroleum coke, such as Figure 1-6 As shown, it includes a bottom plate 1, a first pole 2, a collection frame 3, a crushing box 4, a support plate 6, a crushing frame 7, a mesh plate 8, a first crushing device 12, a first lower hopper 9, and a second lower hopper 10. The throttling device 11 and the first crushing device 12, the four corners of the top of the bottom plate 1 are vertically connected with the first support rod 2 by means of bolt connection, and the top of the bottom plate 1 between the four first support rods 2 is placed There is a collection frame 3, and the tops of the four first poles 2 are connected with a crushing box 4 by means of bolt connection, and a first through hole 5 is opened in the middle of the bottom of the crushing box 4, and the left and right sides of the first through hole 5 The crushing box 4 is connected with a support plate 6 by means of bolt connection. A crushing frame 7 is placed on the sup...

Embodiment 2

[0038] A high-efficiency crushing device for petroleum coke, such as Figure 1-6 As shown, it includes a bottom plate 1, a first pole 2, a collection frame 3, a crushing box 4, a support plate 6, a crushing frame 7, a mesh plate 8, a first crushing device 12, a first lower hopper 9, and a second lower hopper 10. The throttling device 11 and the first crushing device 12, the four corners of the top of the bottom plate 1 are vertically connected with the first support rod 2 by means of bolt connection, and the top of the bottom plate 1 between the four first support rods 2 is placed There is a collection frame 3, and the tops of the four first poles 2 are connected with a crushing box 4 by means of bolt connection, and a first through hole 5 is opened in the middle of the bottom of the crushing box 4, and the left and right sides of the first through hole 5 The crushing box 4 is connected with a support plate 6 by means of bolt connection. A crushing frame 7 is placed on the sup...

Embodiment 3

[0041] A high-efficiency crushing device for petroleum coke, such as Figure 1-6 As shown, it includes a bottom plate 1, a first pole 2, a collection frame 3, a crushing box 4, a support plate 6, a crushing frame 7, a mesh plate 8, a first crushing device 12, a first lower hopper 9, and a second lower hopper 10. The throttling device 11 and the first crushing device 12, the four corners of the top of the bottom plate 1 are vertically connected with the first support rod 2 by means of bolt connection, and the top of the bottom plate 1 between the four first support rods 2 is placed There is a collection frame 3, and the tops of the four first poles 2 are connected with a crushing box 4 by means of bolt connection, and a first through hole 5 is opened in the middle of the bottom of the crushing box 4, and the left and right sides of the first through hole 5 The crushing box 4 is connected with a support plate 6 by means of bolt connection. A crushing frame 7 is placed on the sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com