Production process for thick-specification hot-rolled pickled plate

A hot-rolled pickling and production process technology, applied in metal rolling and other directions, can solve the problems of inability to improve the shape defects of hot-rolled raw materials, and achieve the effect of improving the shape and surface finish, wide range of specifications, and increasing added value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

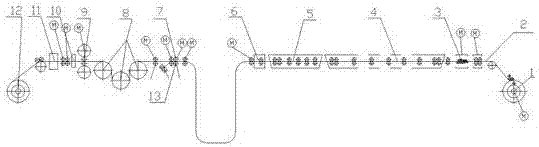

[0019] attached figure 1 It is a specific embodiment of the present invention. The invention is a production process of thick-gauge hot-rolled pickling plate, which includes the following steps:

[0020] 1) A coil preparation station is arranged behind the feeding device to form the coil feeding and pre-coil preparation part of the push-pull pickling unit; the feeding device is mainly responsible for the feeding of hot-rolled raw materials The car lifts the raw material coils to the feeding device, and transports the raw material coils to the weighing device through the walking transport beam. After weighing, the coils are transported to the unbundling position by the coil shuttle car to unbundle; The main function of the coil preparation station is to prepare the uncoiler 1 for the uncoiler 1 by straightening the tape head and cutting off the unsuitable part of the tape head;

[0021] 2) The feeding device and the center line of the steel coil preparation station are vertic...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap