A method of rapid creep aging forming

A technology of creep aging forming and creep aging, applied in the direction of forming tools, manufacturing tools, metal processing equipment, etc., can solve the problems that the forming temperature cannot be simply increased, the forming efficiency is accelerated, and the efficiency is not high, so as to achieve easy control and application Wide range of useful effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

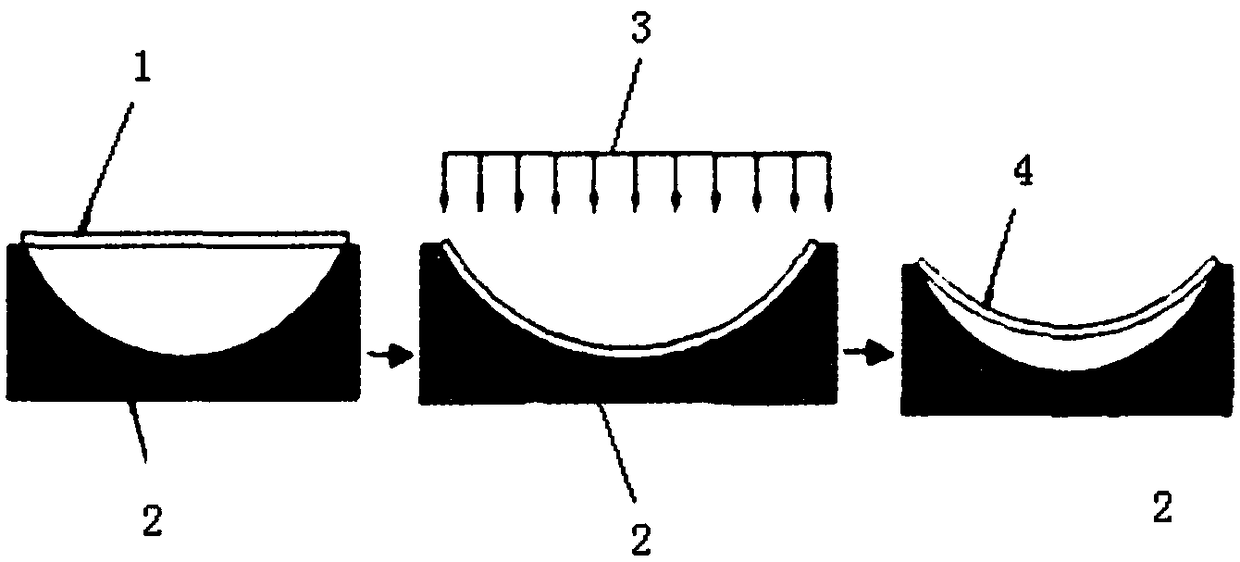

[0047] see Figure 4 , a method for rapid creep age forming, specifically comprising the following steps:

[0048] The first step, the component and the mold in the autoclave are tightly bonded under load, specifically: apply mechanical force to the component to make the component and the mold fit tightly, and then move the component and mold to the hot press under load or put the component and the mold in a vacuum bag first and then vacuumize, then send the component and the mold into the autoclave, and finally pressurize to make the component close to the mold;

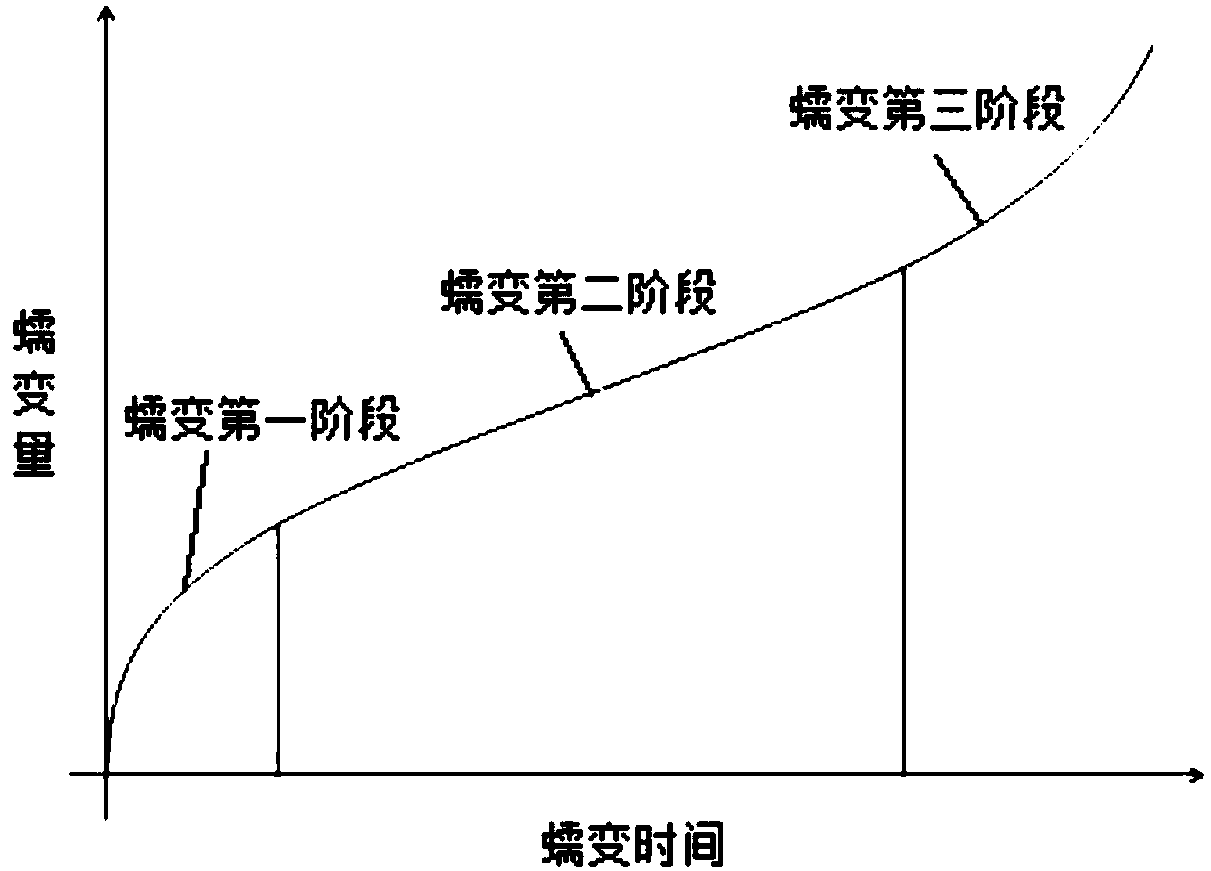

[0049] The second step is to increase the internal temperature of the autoclave to 10°C-50°C above the creep aging temperature T, and keep it warm for 1 hour, and the heating rate during this process is 3°C-5°C / min;

[0050] The third step is to reduce the internal temperature of the autoclave to the creep aging temperature T, and keep it warm for t2 hours, where t2 is 3-4 times of t1, and the cooling rate during t...

Embodiment 2

[0054] In this embodiment, taking 2219 aluminum alloy as an example, the specific method of creep aging forming is disclosed. The details are as follows: specifically, the following steps are included:

[0055] The first step, the component and the mold in the autoclave are closely bonded under the load, specifically: firstly attach the component and the mold to a vacuum bag and then vacuumize, then send the component and the mold together into the autoclave, and finally add Press to make the component close to the mold;

[0056] The second step is to raise the internal temperature of the autoclave to 200°C (the creep aging temperature of 2219 aluminum alloy is 165°C), and keep it warm for 60 minutes. During this process, the heating rate is 3°C-5°C / min;

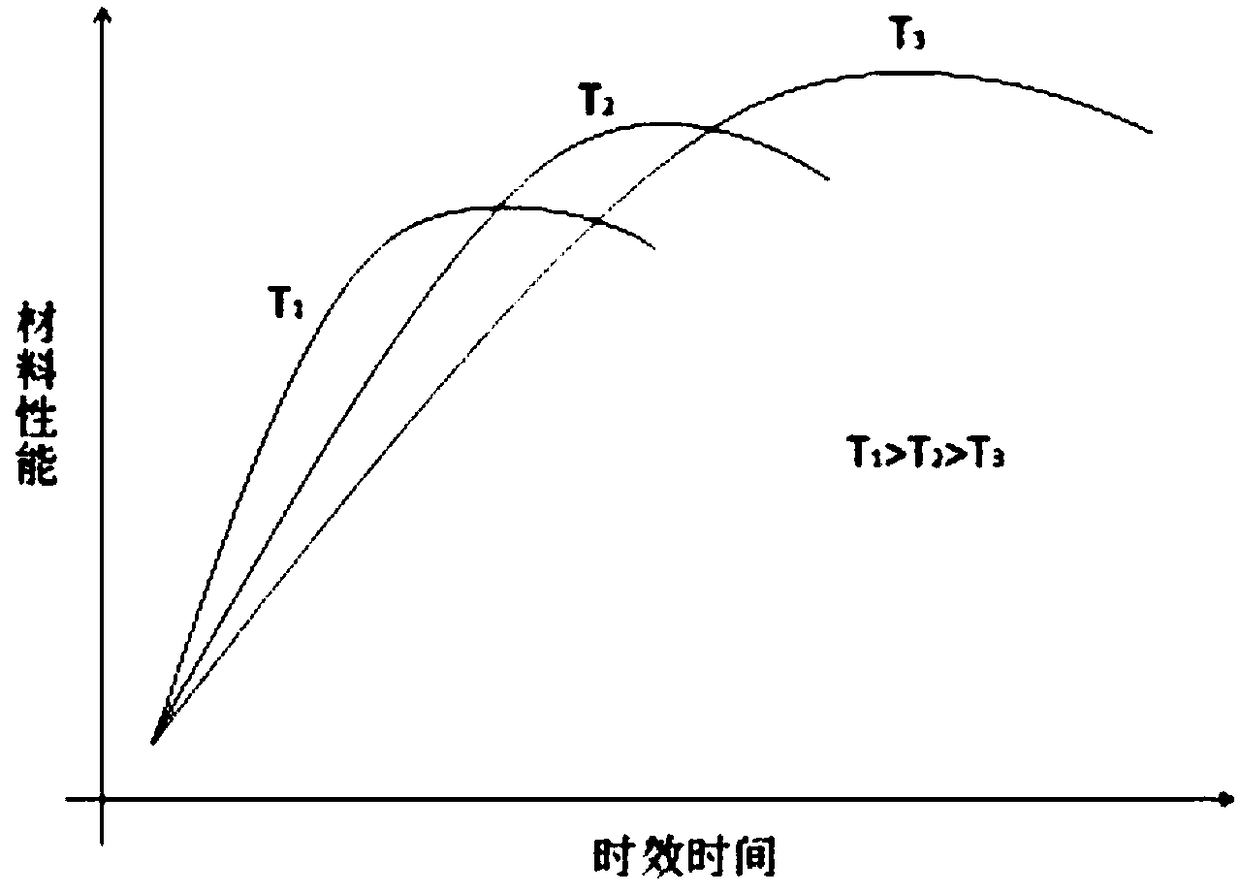

[0057] Step 3: Lower the temperature inside the autoclave to the creep aging temperature of 165°C. For the holding time, see Figure 5-Figure 7 , the cooling rate during this process is 3°C-5°C / min;

[0058] The fourth ste...

Embodiment 3-4

[0062] Embodiment 3-4 differs from embodiment 2 only in that:

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com