Multifunctional automobile ceiling handle and fabrication process thereof

The technology of automobile ceiling and ceiling handle, which is applied in the field of auto parts, can solve the problems of increasing the cooling time in the mold, long production cycle of the handle, and much material consumption, and achieves the effects of accelerating the crystallization speed, accelerating the molding, and reducing the consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

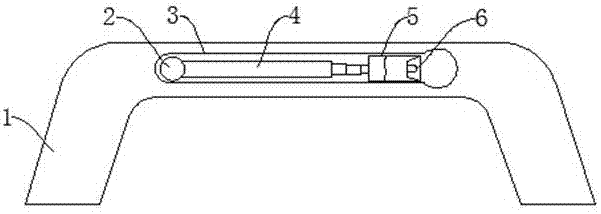

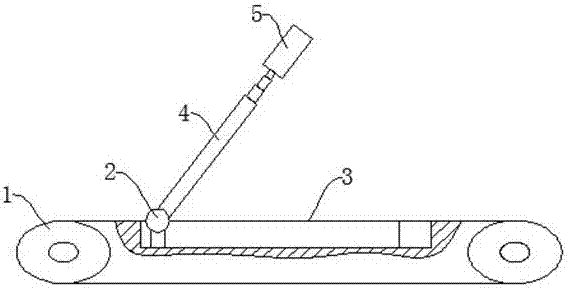

[0030] The present invention will be further described below in conjunction with accompanying drawing:

[0031] Such as Figure 1-Figure 2 As shown, a multifunctional car ceiling handle includes a handle body 1, a groove 3 is arranged on the handle body 1, a rotating seat 2 is installed in the groove 3, and a telescopic rod is installed on the rotating seat 2 4. A lampshade 5 is installed on the top of the telescopic rod 4, and a lamp bead 6 is installed inside the lampshade 5.

[0032] In this embodiment, the handle body 1 is injection molded from PP or PE plastic.

[0033] In this embodiment, the groove 3 is a long groove, and one end of the long groove close to the lampshade 5 is provided with a circular groove connected with the long groove, and the groove 3 is used to store the telescopic rod 4 and the lampshade 5.

[0034] In this embodiment, the swivel seat 2 is a spherical universal swivel seat, which is fixed on the bottom of the groove 3 by bolts. The swivel seat ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com