Combined type battery frame assembly of electric automobile

A technology of electric vehicles and battery frames, applied in the direction of electric power devices, power devices, vehicle components, etc., can solve problems such as unreasonable structural design and fixing methods, occupying the upper space of the frame, and unreasonable layout design, etc., to achieve load lifting ability and long-distance driving ability, strong ability to withstand vertical loads, and the effect of realizing lightweight design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

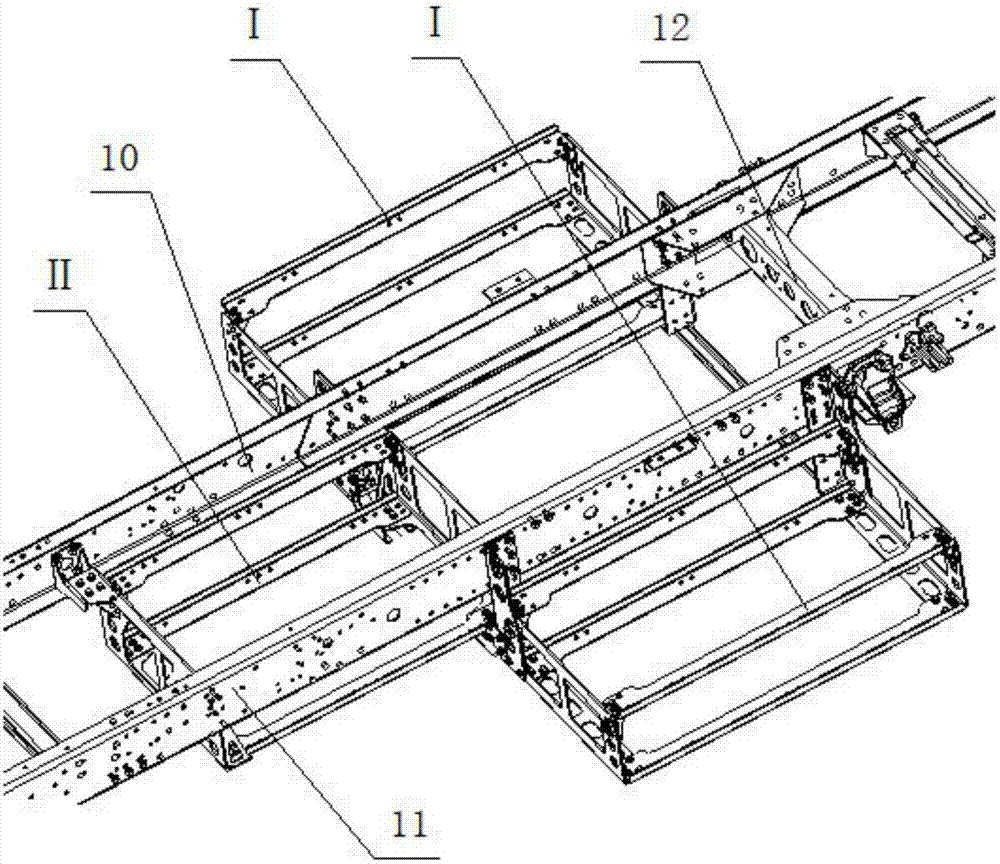

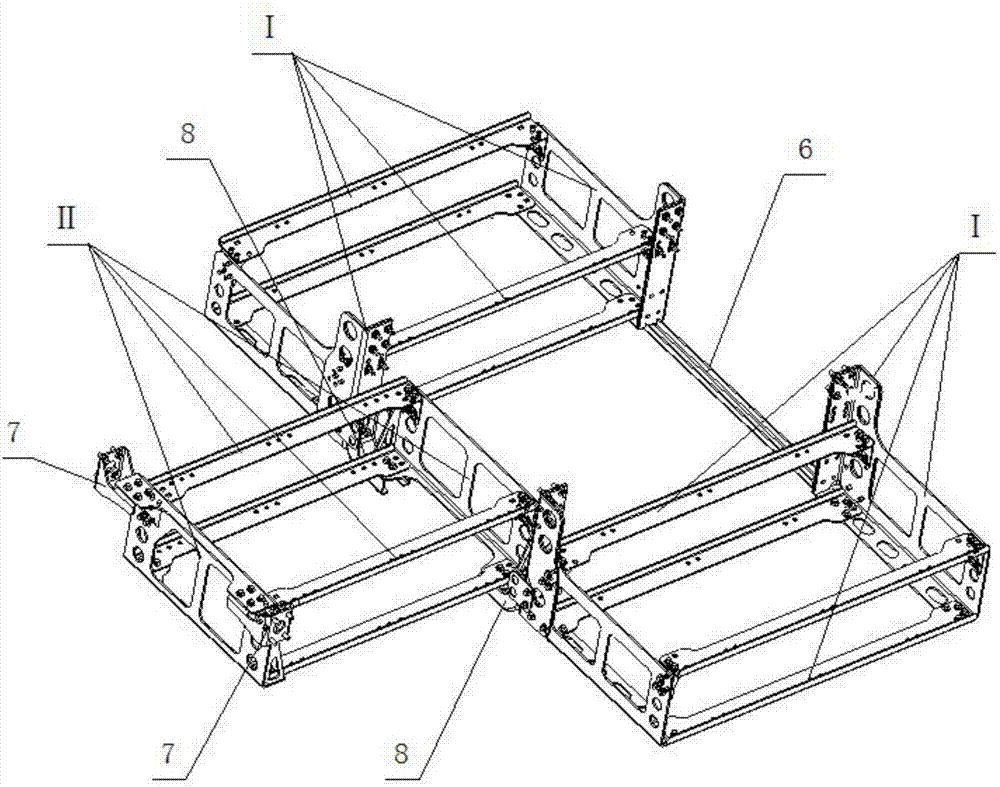

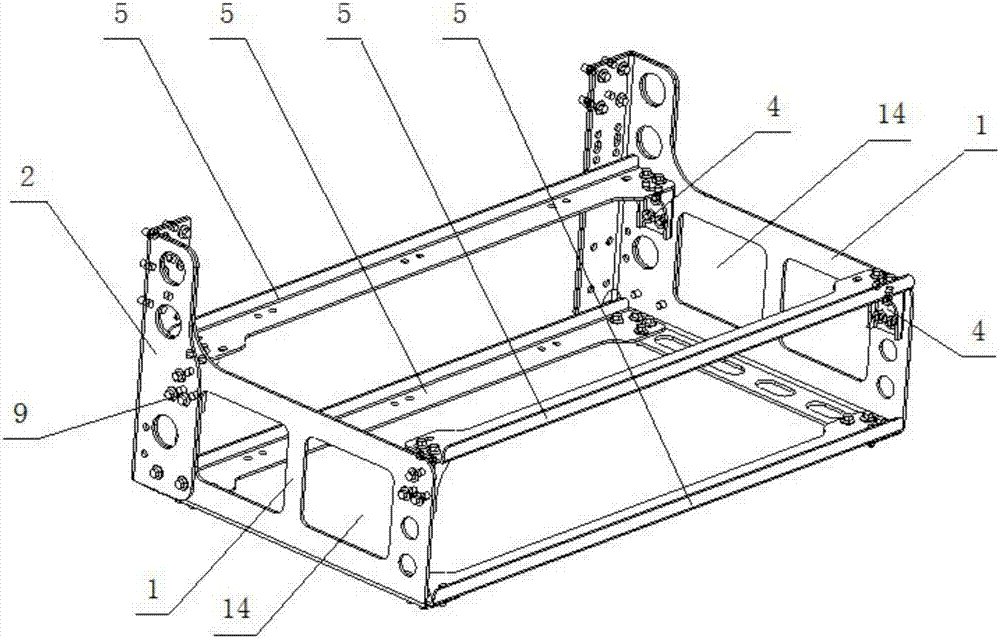

[0049] Such as Figure 1 to Figure 2 As shown, a combined battery frame assembly for an electric vehicle includes two side battery frames I fixed on the outside of the left longitudinal beam 10 and the right longitudinal beam 11 of the vehicle frame as mirror images, and the middle battery frame I fixed between the left and right longitudinal beams of the vehicle frame. Box II. The two sides of the front end of the middle battery frame II are respectively fixed to the left longitudinal beam 10 and the right longitudinal beam 11 of the frame through two upper brackets 7, and the two sides of the rear end of the middle battery frame II are connected to the side battery through two lower brackets 8. Both sides of the front end of the frame I are fixed, and between the battery frames I on both sides, a horizontal support rod 6 is provided near the rear end, and the support rod 6 is specifically arranged at the bottom of the battery frame I on both sides.

[0050] Such as figure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com