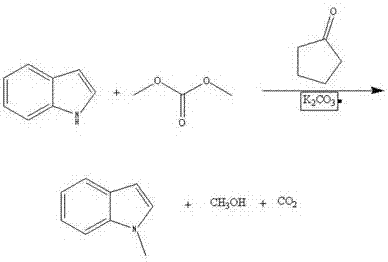

Method for synthesizing 1-methylindole as Tagrisso intermediate

A technology of methyl indole and synthetic method, which is applied in the field of organic synthesis, can solve the problems of being prone to danger, unsuitable for laboratory and industrial production, etc., and achieves the effects of simple post-processing, stable product quality and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Add 140.6g of cyclopentanone, 20g of indole, 10g of potassium carbonate, and 10.3g of dimethyl carbonate into the reaction flask, stir, and raise the temperature to 120°C for a reflux reaction. After 2 hours of reaction, stop heating and wait for no reflux , Sampling detection, the purity of the intermediate state is above 99%; add 5.1g of dimethyl carbonate, heat up to 115°C to reflux, and react for 4 hours; then drop to room temperature and add 3.3g of dimethyl carbonate, heat up to 115°C to Reflux and continue to react for 2 hours; then drop to room temperature and add 3.3 g of dimethyl carbonate, raise the temperature to 115°C to reflux and continue to react for 12 hours; About 90% of the solvent is distilled under high pressure, the pressure is about 0.1MP, and the temperature is about 50-70°C. It must be slow at the beginning, otherwise, add 200g of water to the remaining product, stir for 30 minutes, and stand at 30-35°C Place for 2 hours, separate layers, the lo...

Embodiment 2

[0034] Add 100.4g of cyclopentanone, 16g of indole, 8g of potassium carbonate, and 8.4g of dimethyl carbonate into the reaction flask, stir, and raise the temperature to 120°C for a reflux reaction. Stop heating after 2 hours of reaction, and wait for no reflux. Sampling and testing. The purity of the intermediate state is above 99%; add 4.1g of dimethyl carbonate, raise the temperature to 116°C to reflux, and react for 4 hours; then cool down to room temperature, add 3.1g of dimethyl carbonate, raise the temperature to 116°C to reflux to continue the reaction 2 hours; then lowered to room temperature and added 3.1 g of dimethyl carbonate, raised the temperature to 116°C to reflux and continued to react for 12 hours; stopped heating, waited for no reflux, took a sample for detection, the remaining raw materials were less than 2%, stopped the reaction, and distilled out under reduced pressure About 90% of the solvent, the pressure is about 0.1MP, the temperature is about 50-55°C...

Embodiment 3

[0036] Add 160.7g of cyclopentanone, 22g of indole, 12g of potassium carbonate, and 11.24g of dimethyl carbonate into the reaction flask, stir, and raise the temperature to 120°C for a reflux reaction. Stop heating after 2 hours of reaction, and wait for no reflux. Sampling and testing. The purity of the intermediate state is above 99%; add 6.2g of dimethyl carbonate, raise the temperature to 120°C to reflux, and react for 4 hours; then lower the temperature to room temperature and add 4.1g of dimethyl carbonate, raise the temperature to 120°C to reflux to continue the reaction 2 hour; then drop to room temperature and add 4.1g of dimethyl carbonate, heat up to 120°C to reflux and continue to react for 12 hours; stop heating, wait for no reflux, take a sample for detection, the remaining raw material is less than 2%, stop the reaction, and distill out about 90% solvent, the pressure is about 0.1MP, the temperature is about 65-70°C, it should be slow at the beginning, otherwise,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com