Non-lubricated railway turnout slide plate

A sliding bed plate, lubrication-free technology, applied in the direction of roads, tracks, buildings, etc., can solve the problems of short lubrication cycle, short lubricant lubrication cycle, large fluctuations in the deployment ratio, etc., to achieve high safety factor and clean solid lubricating materials Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

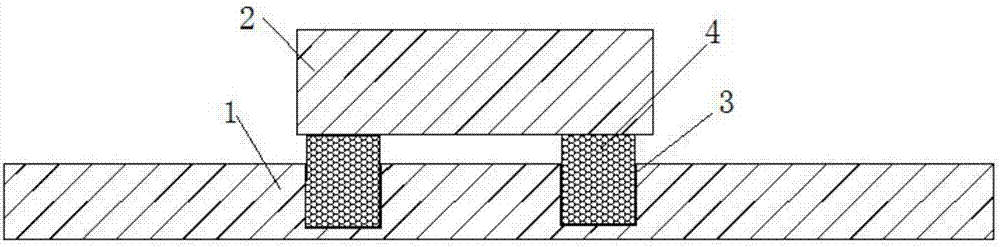

[0025] Such as figure 1 One of the shown embodiments is a lubrication-free railway turnout sliding bed, including a sliding bed 1 and a point rail 2 moving on the sliding bed 1, and also includes a support block 4, on the surface of the two ends of the sliding bed 1 A support hole 3 with a square cross section is set, and the support hole 3 is strip-shaped and the inside is fitted with a lubricating support block 4. The height of the lubricating support block 4 is higher than the height of the surface of the sliding bed plate 1, and the The bottom surface of the point rail 2 is horizontally attached to the top surface of the lubricating support block 4; the lubricating support block 4 is a square column made of solid lubricating material, and the solid lubricating material is one of graphite, molybdenum disulfide or Teflon .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com