Machine used for foundation flattening

A foundation and machine technology, applied in construction, building construction, etc., can solve the problems of high labor intensity, delay in construction period, slow speed, etc., and achieve the effect of reducing labor intensity and speeding up the progress of the project.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

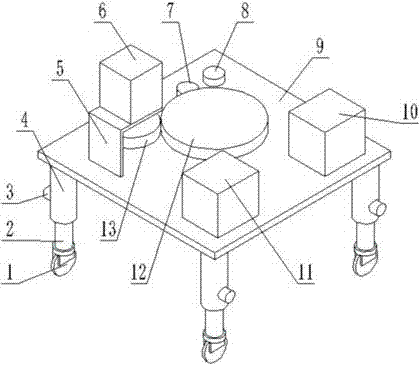

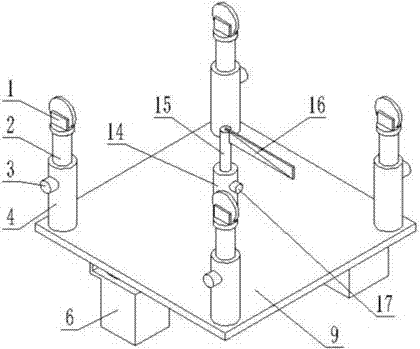

[0017] Combine below figure 1 , 2 Explaining this embodiment, the present invention relates to a construction engineering machine, more specifically a construction ground leveling machine, including: universal wheel 1, telescopic leg 2, set screw I3, telescopic sleeve 4. Motor mount 5, motor 6, forward button 7, reverse button 8, support plate 9, battery I 10, battery 11, driven gear

[0018] 12. The driving gear 13, the sleeve shaft 14, the telescopic rod 15, the scraper 16 and the set screw Ⅱ17 are driven by the motor to rotate the scraper to level the foundation, which speeds up the project progress and reduces the labor intensity.

[0019] The universal wheel 1 is fixedly connected to the lower end of the telescopic leg 2, and the universal wheel 1 provides convenience for the movement of the ground scraper for construction. The upper end of the telescopic leg 2 is inserted into the telescopic sleeve 4, the tightening screw I3 fixes the telescopic leg 2 and the telescopic sleev...

specific Embodiment approach 2

[0021] Combine below figure 1 , 2 This embodiment will be described. This embodiment will further explain the first embodiment. There are four universal wheels 1, telescopic legs 2, set screws I3, and telescopic sleeves 4, and they are evenly distributed on the support plate 9. The four corners make the structure of the building foundation scraper reasonable and ensure the support of the support plate 9 is stable.

specific Embodiment approach 3

[0023] Combine below figure 1 , 2 This embodiment will be described. This embodiment will further explain the first embodiment. The battery I10 and the battery 11 have the same model, and the battery I10 and the battery 11 ensure that the construction ground scraper can continuously work.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap