Support system of steam turbine generator unit

A technology for steam turbine generator sets and generator sets, which is applied to engine components, machines/engines, mechanical equipment, etc., and can solve problems such as large engineering investment, inability to solve expansion and stress problems, and inability to greatly reduce high temperature and high pressure steam pipeline straight pipes, etc. , to achieve the effect of saving investment, reducing pressure loss and reducing usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Such as Figure 4 As shown, it is a schematic diagram of a specific embodiment 1 of a support system of a turbogenerator set of the present invention. Among them, the boiler adopts a tower furnace, and the high-level steam turbine and the boiler (viewed from the right side of the furnace to the left side of the furnace) are arranged in parallel in the horizontal direction.

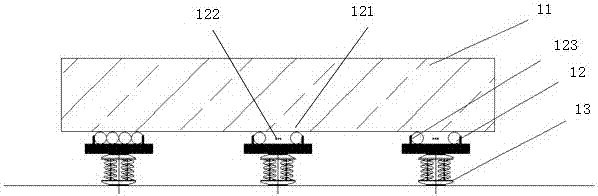

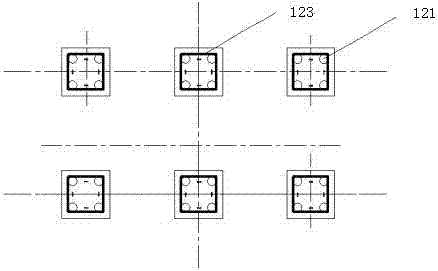

[0029] The high-level steam turbine in this embodiment adopts the support system of the present invention, mainly including support system 1, high-level steam turbine 2, outlet header 3 of the final reheater, outlet header 4 of the final superheater, high-pressure cylinder 5 and medium-pressure cylinder 6 , Hot re-steam pipes 3' and 3'', main steam pipes 4' and 4''.

[0030] Among them, the outlet header 3 of the final stage reheater and the outlet header 4 of the final superheater are all attached to the high-level steam turbine 1. Since the support system 1 adopts the support system of the present...

Embodiment 2

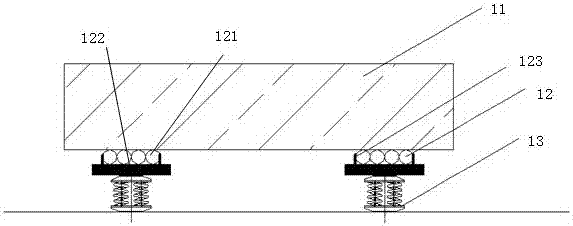

[0034] Such as Figure 5 As shown, it is a schematic diagram of Embodiment 2 of a support system of a turbogenerator set of the present invention. Among them, the boiler adopts a tower furnace, and the high-level steam turbine and boiler (viewed from the right side of the furnace to the left side of the furnace) are arranged vertically in the horizontal direction.

[0035]The high-level steam turbine in this embodiment adopts the support system of the present invention, mainly including support system 1, high-level steam turbine 2, outlet header 3 of the final reheater, outlet header 4 of the final superheater, high-pressure cylinder 5 and medium-pressure cylinder 6 , Hot re-steam pipes 3' and 3'', main steam pipes 4' and 4''.

[0036] Among them, the outlet header 3 of the final stage reheater and the outlet header 4 of the final superheater are all attached to the high-level steam turbine 1. Since the support system 1 adopts the support system of the present invention, that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com