Multi-ball board standard for multi-sensor measurement system and joint error detection method

A multi-sensor, measurement system technology, applied in the standard field, to achieve the effect of simple layout, guaranteed accuracy, simple and controllable sampling strategy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

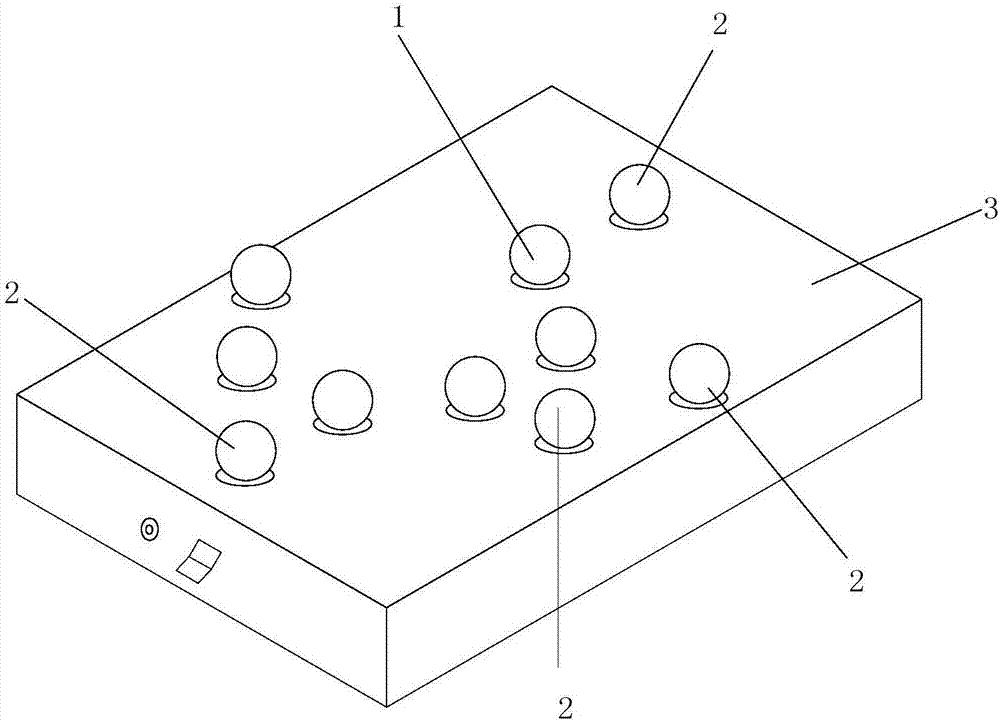

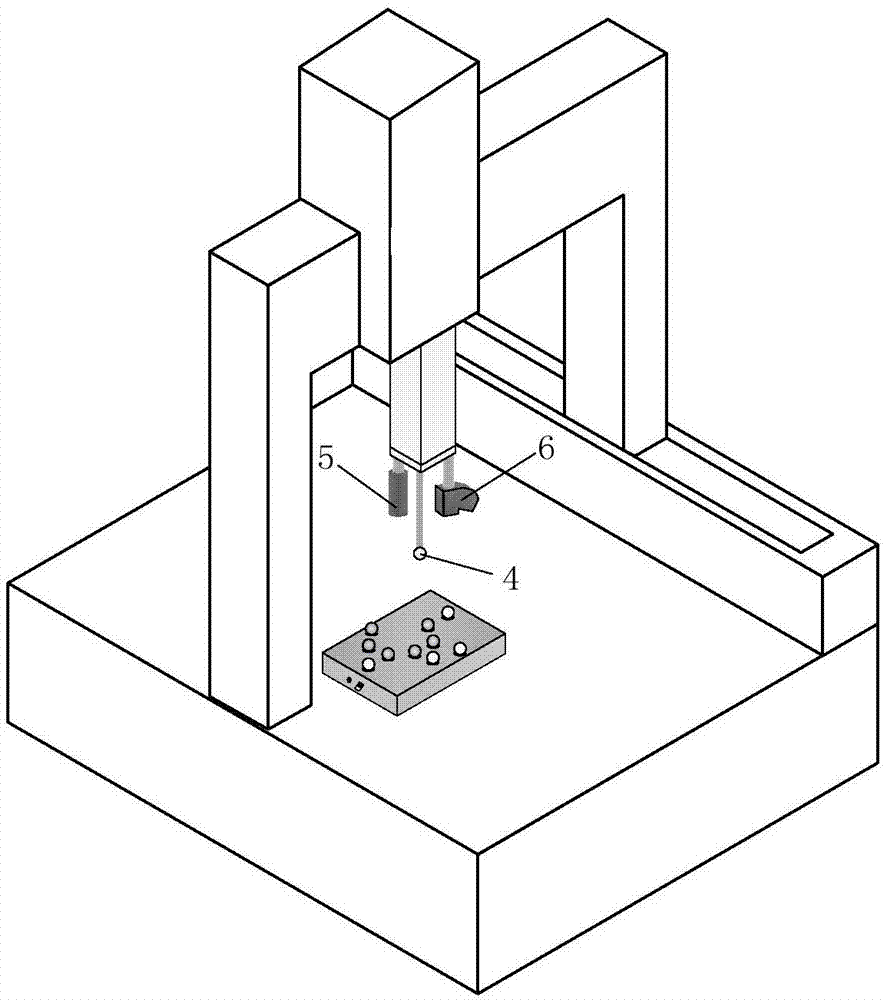

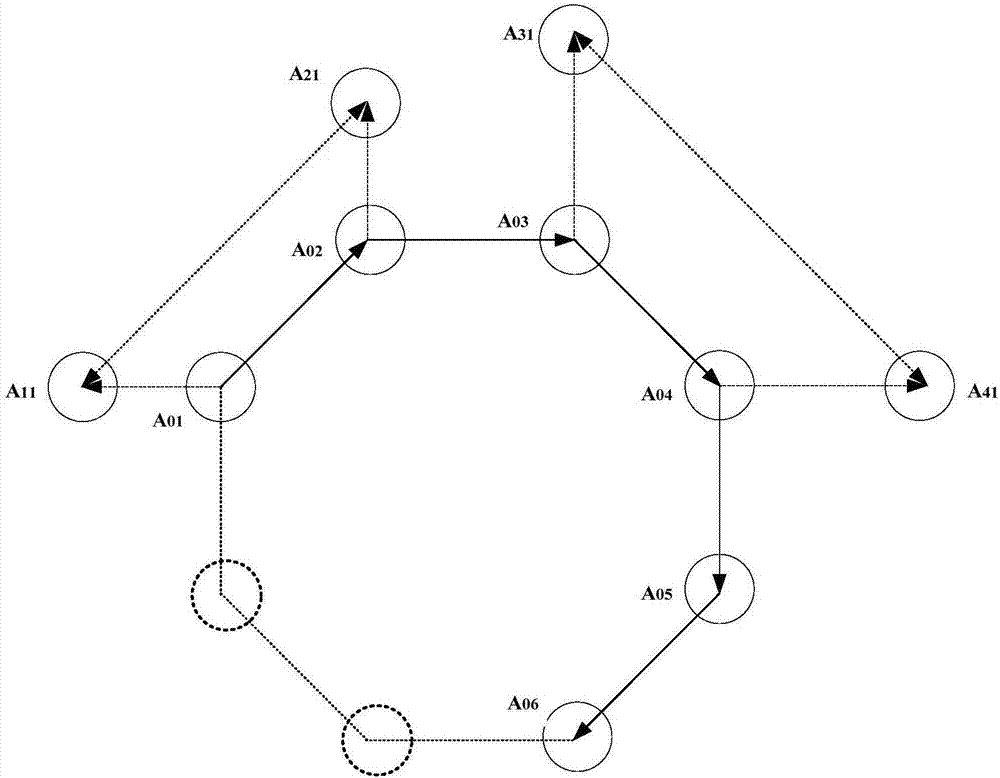

[0046] Such as figure 1 and image 3 As shown, a multi-ball plate etalon for a multi-sensor measurement system includes a plate body, and standard balls are distributed on the upper surface of the plate body according to a topological structure; the topological structure includes a regular octagonal path extending arrangement The first-level node is located on the vertices of the regular octagon; the first-level node derives at least a second-level node according to the following rules: take two adjacent upper-level nodes as a derived group and derive two The two upper-level nodes in this derivation group derive their own next-level nodes with equal extension distance along the ray direction with itself as the end point and the connection line between them at 135°. level nodes; the standard spheres are fixedly installed on the board corresponding to the positions of each node. The standard ball can be made of ruby, ceramics or high-speed steel. If the standard ball is made o...

specific Embodiment approach 2

[0071] Such as Figure 7 As shown, a multi-ball plate etalon for a multi-sensor measurement system includes a plate body, and standard balls are distributed on the upper surface of the plate body according to a topological structure; the topological structure includes a first-order node extending according to a regular quadrilateral path , the first-level node is located on the vertices of a regular quadrilateral; the first-level node derives at least a second-level node according to the following rules: two adjacent upper-level nodes are used as a derived group and two lower-level nodes are derived outward First-level nodes, the two upper-level nodes in this derived group are respectively derived from the respective lower-level nodes with equal extension distance along the ray direction with itself as the end point and the connection line between them at 135° ; The standard spheres are fixedly installed on the board corresponding to the positions of the nodes.

[0072] In th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com