Flame Ionization Detector Having Special Burner Nozzle, And Internal Combustion Engine, Power Station And Burner Nozzle

A flame ionization and detector technology, used in gas fuel burners, burners, burners, etc., can solve the problems of increasing nonlinear characteristics of conversion rate, strong changes in response factors, excessive compensation, etc., and achieve increased applications. Effective range, reduced oxygen error, reduced consumption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

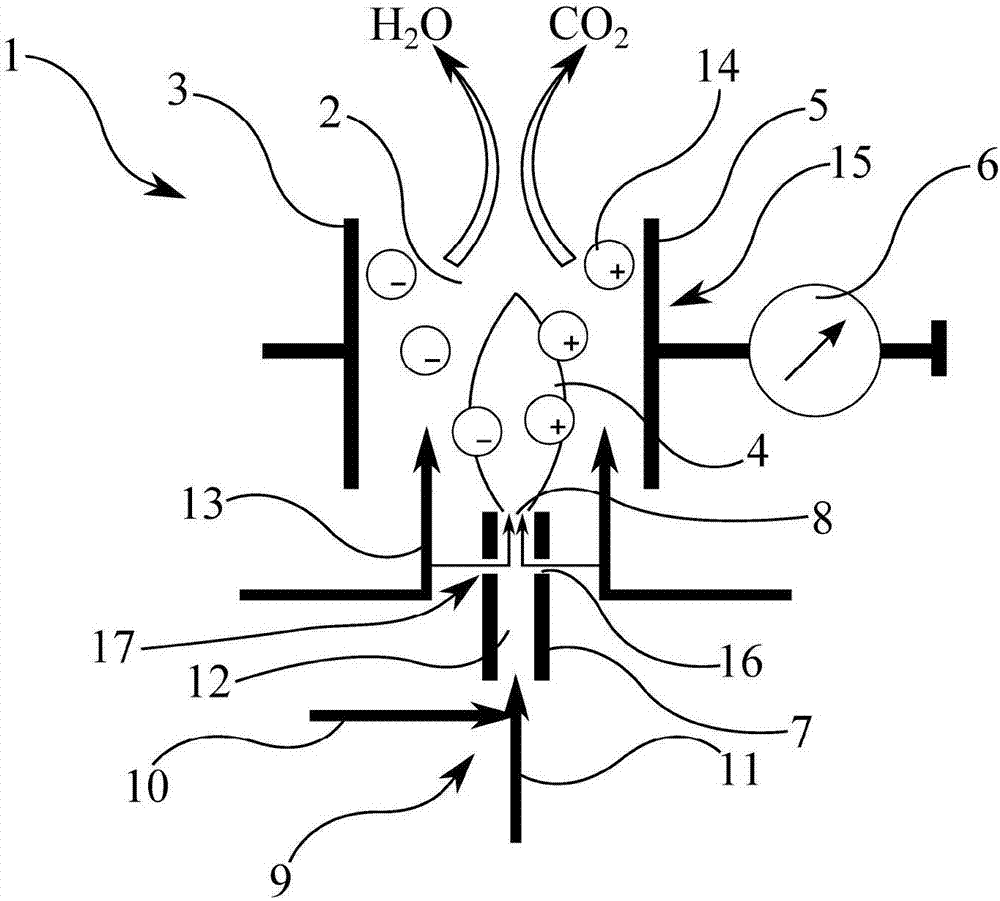

[0029] figure 1 The FID 1 is shown in FIG. 1 with a combustion chamber 2 in which an electrode device 3 is arranged to measure the current from the gas flame 4 to the electrode 5 of the electrode device 3. Here, the current measuring device 6 includes an amplifier not shown further, so that the generally very small current from the gas flame 4 can be measured.

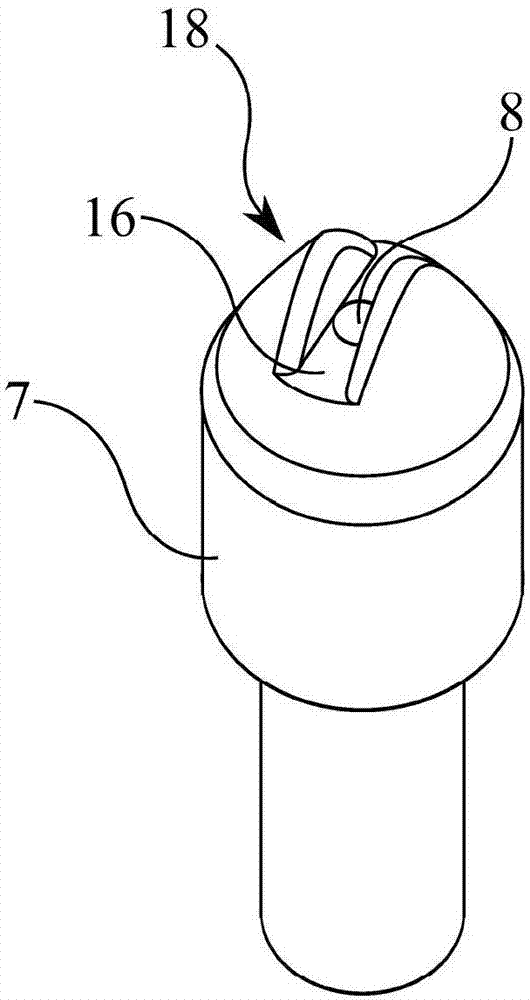

[0030] A burner nozzle 7 with a nozzle 8 on the output side projects out of the combustion chamber 2 to eject a gas mixture 9 to be ignited between the electrode devices 3. The gas mixture 9 is formed on the input side of the burner nozzle 7 by mixing the oxygen-containing combustion gas 10 and the carbon-containing measurement gas 11 and transporting them to the nozzle 8 through the transmission channel 12.

[0031] Additionally, outside the burner nozzle, oxygen-containing combustion air 13 is introduced into the combustion chamber 2. This leads to reaction with the combustion gas 10, thereby forming water (H 2 O) and ca...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap