Iterative-ADP-algorithm-based optimal control method for wastewater treatment

A technology of sewage treatment and optimal control, applied in the direction of adaptive control, general control system, control/regulation system, etc., can solve the problems of large error, low control precision of sewage treatment, large power consumption and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

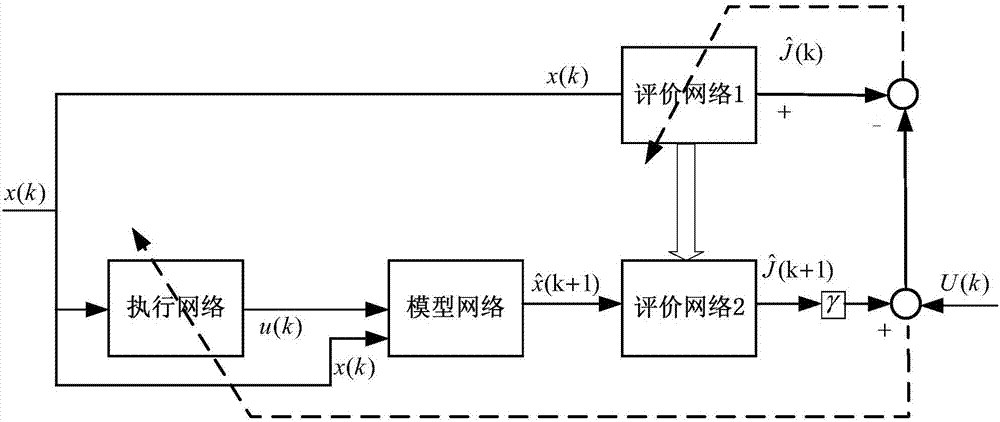

Method used

Image

Examples

Embodiment Construction

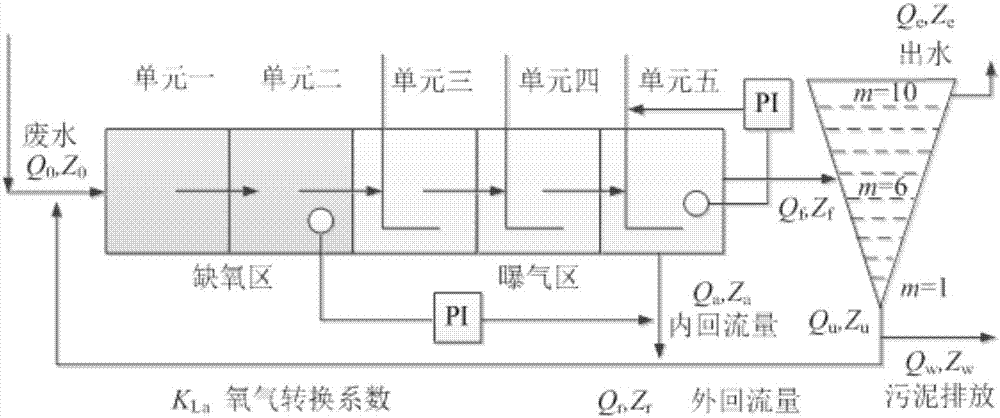

[0097] The BSM1 model is a standard model proposed by the International Water Association (IWA) for testing control strategies in wastewater treatment processes (such as figure 1 shown), it consists of a biochemical reaction tank and a secondary sedimentation tank. The biochemical reaction tank is divided into five zones, the first two zones are anoxic zones, and the last three zones are aerobic zones. The biochemical reaction tank adopts the IAWQ proposal The ASM1 mathematical model is used for simulation. The sewage from the biochemical reaction tank enters the secondary sedimentation tank for mud-water separation. After the separation, the upper layer is treated as effluent and discharged into the receiving water body. The other part is discharged as excess sludge.

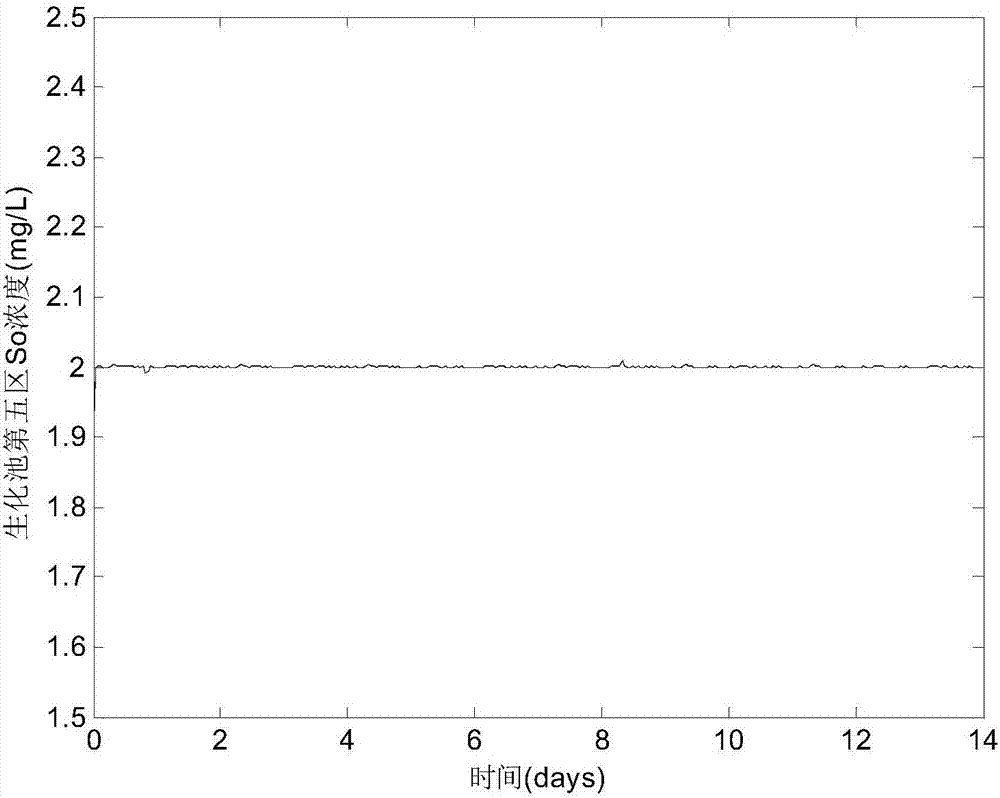

[0098] The control target of this BSM1 simulation experiment is the dissolved oxygen concentration S of the fifth zone O,5 and the nitrate nitrogen concentration S of the second partition NO,2 Respectively m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com