Method for designing new processing data by scanning reproduced die edge

A technology for processing data and optical scanning equipment, applied in image data processing, electrical digital data processing, special data processing applications, etc., can solve the problems of occupying equipment resources, wasting labor costs, prolonging the manufacturing cycle, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

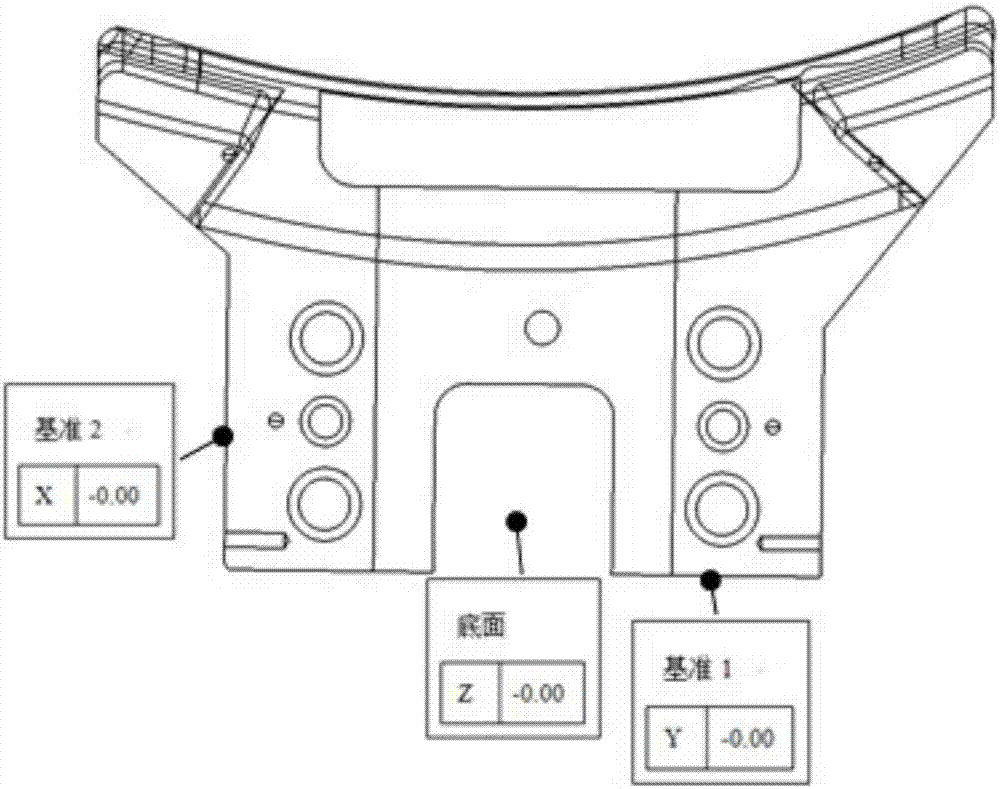

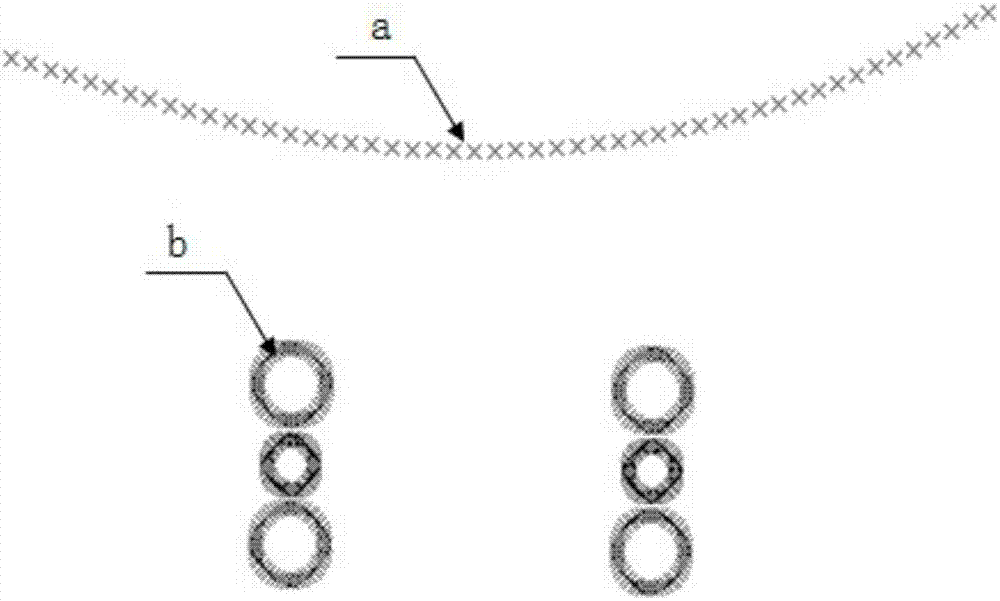

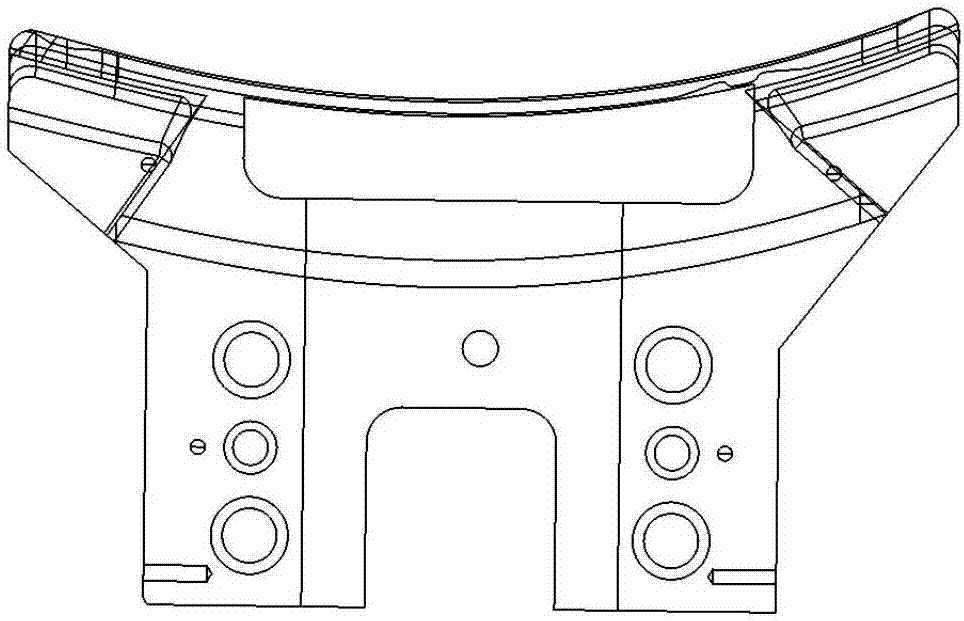

[0047] The present invention will be further described below in conjunction with the accompanying drawings and examples: the mold insert after debugging is worn or damaged in the process of production and use, and needs to be remanufactured, that is, the mold insert to be remade. In order to ensure the quality of the scanned data of the mold insert to be reproduced, it is necessary to process defects such as benchmarks, profiles, and contours of the mold insert to be reproduced before scanning, and then use ATOS optical scanning equipment and three-coordinate measuring machine to treat Scan the remade mold insert to generate the point cloud data of the solid surface of the mold insert to be remade and the point cloud data of the outline and holes. When designing the new processing data of the mold insert to be reproduced, the point cloud data obtained by scanning the mold insert to be reproduced is first imported into the CATIA software environment of the original processing da...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com