Method for tenderizing beef

A technology for tenderizing and beef, applied in the functions of food ingredients, food science, application, etc., can solve the problems of poor taste, poor quality of beef meat, unsafe chemical methods, etc., achieve fast speed, good meat quality, and improve effect of tenderness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

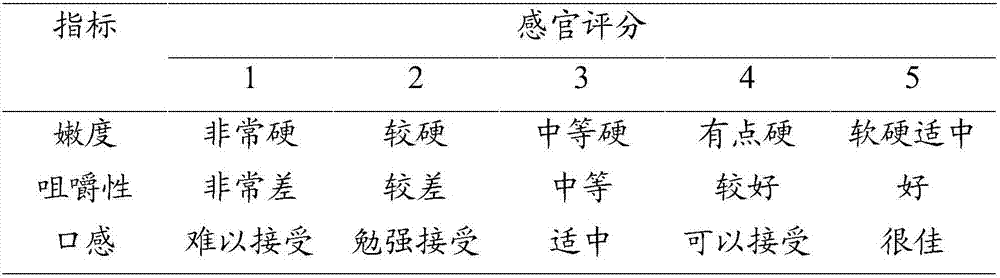

Examples

Embodiment 1

[0025] A method for tenderizing beef, comprising the steps of:

[0026] Step 1, prepare a 0.1g / 100ml papain solution with a phosphate buffer solution with a pH of 5.7 as a solvent, and store it at 55°C for later use;

[0027] Wherein, the phosphate buffer solution is a phosphate buffer solution with a pH of 5.7 at 0.1mol / L;

[0028] Step 2, remove the fascia and fat from the outer tenderloin of fresh beef, trim the edges neatly, and cut into slices, the size of the slices is 8cm×10cm×1.2cm;

[0029] Step 3, inject the papain solution into the meat slices, inject 10ml of the papain solution per 100g of the meat slices, then place the meat slices in a sealed bag, and enzymatically hydrolyze them for 10 minutes to obtain the enzymatic hydrolyzed meat slices;

[0030] Step 4, put the enzymatically hydrolyzed meat slices together with the sealed bag into the tumbler of the vacuum tumbler for vacuum tumbling, the vacuum degree is -0.08MPa, the temperature is 8°C, the continuous tum...

Embodiment 2

[0032] A method for tenderizing beef, comprising the steps of:

[0033] Step 1, prepare a 0.05g / 100ml papain solution with a phosphate buffer solution with a pH of 5.7 as a solvent, and store it at 55°C for later use;

[0034] Wherein, the phosphate buffer solution is a phosphate buffer solution with a pH of 5.7 at 0.2mol / L;

[0035] Step 2, remove the fascia and fat from the outer tenderloin of fresh beef, trim the edges neatly, and cut into slices, the size of the slices is 8cm×10cm×1.2cm;

[0036] Step 3, injecting the papain solution into the meat slices, injecting 10ml of the papain solution per 100g of the meat slices, then placing the meat slices in a sealed bag, and enzymatically hydrolyzing them for 8 minutes to obtain the enzymolyzed meat slices;

[0037] Step 4, put the enzymatically hydrolyzed meat slices together with the sealed bag into the tumbler of the vacuum tumbler for vacuum tumbling, the vacuum degree is -0.08MPa, the temperature is 8°C, the continuous tu...

Embodiment 3

[0039] A method for tenderizing beef, comprising the steps of:

[0040] Step 1, prepare a 0.15g / 100ml papain solution with a phosphate buffer solution with a pH of 5.7 as a solvent, and store it at 55°C for later use;

[0041] Wherein, the phosphate buffer solution is a phosphate buffer solution with a pH of 5.7 at 0.1mol / L;

[0042] Step 2, remove the fascia and fat from the outer tenderloin of fresh beef, trim the edges neatly, and cut into slices, the size of the slices is 8cm×10cm×1.2cm;

[0043] Step 3, injecting the papain solution into the meat slices, injecting 10ml of the papain solution per 100g of the meat slices, then placing the meat slices in a sealed bag, and enzymatically hydrolyzing them for 15 minutes to obtain the enzymolyzed meat slices;

[0044] Step 4, put the enzymatically hydrolyzed meat slices together with the sealed bag into the tumbler of the vacuum tumbler for vacuum tumbling, the vacuum degree is -0.08MPa, the temperature is 8°C, the continuous t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shear force | aaaaa | aaaaa |

| Shear force | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com