An intermittent clamping and feeding device and pipe cutting equipment

A technology of clamping feeding and clamping device, applied in pipe shearing device, shearing device, shearing machine equipment and other directions, can solve the problems of expensive equipment, low precision, labor-intensive, etc., saving labor cost and high work efficiency , easy to use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

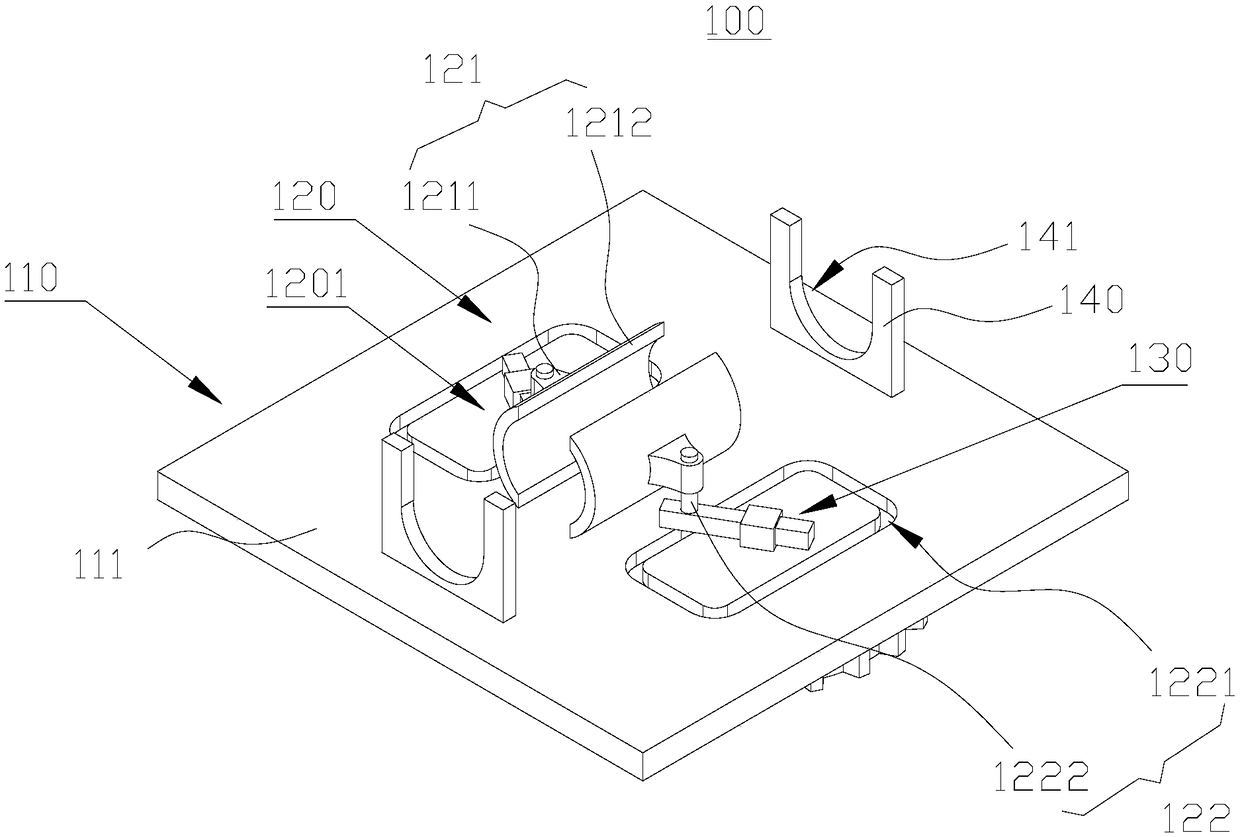

[0034] This embodiment provides an intermittent clamping and feeding device 100, refer to figure 1 As shown, a mounting table 110 and a clamping device 120 disposed on the mounting table 110 are included.

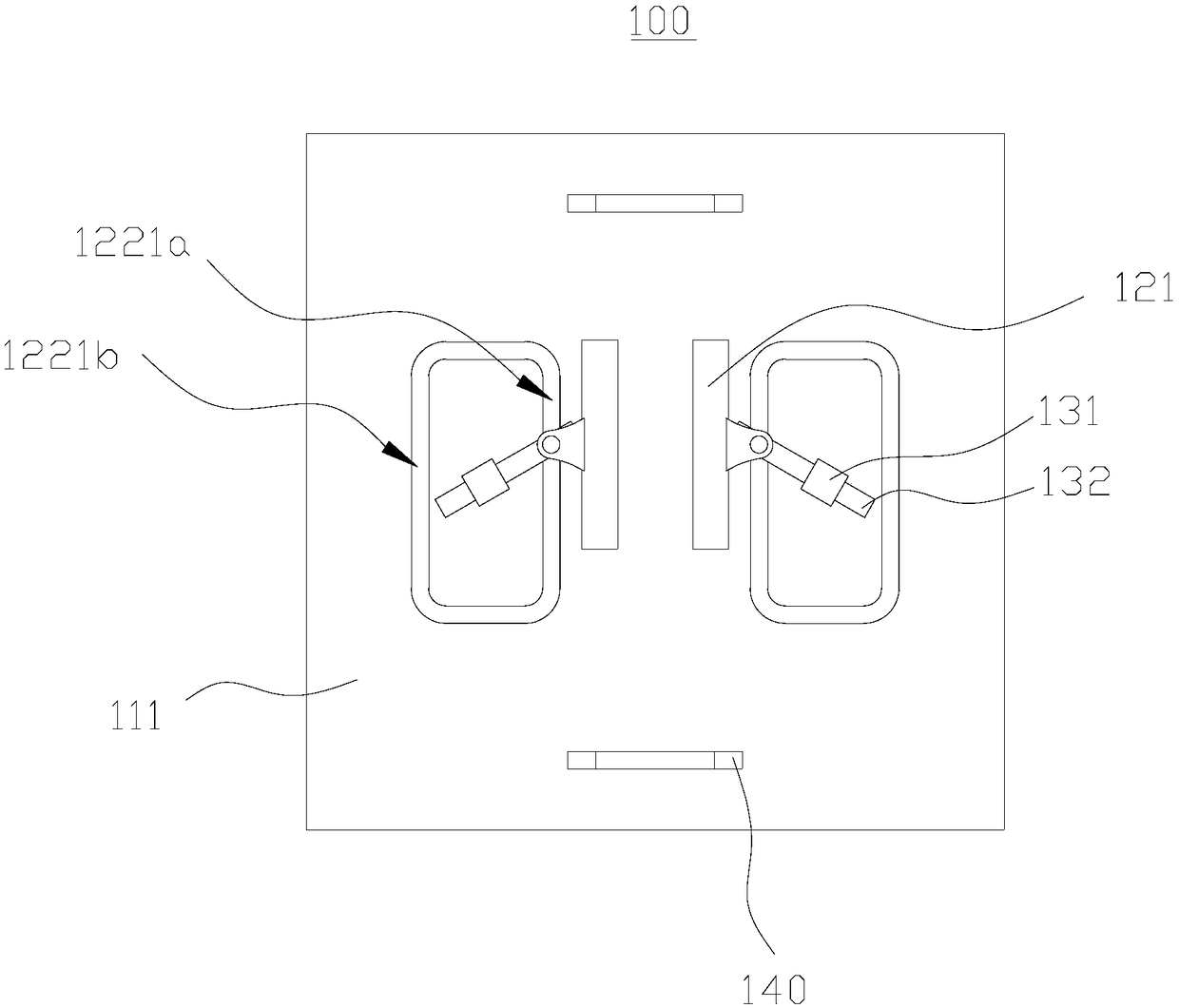

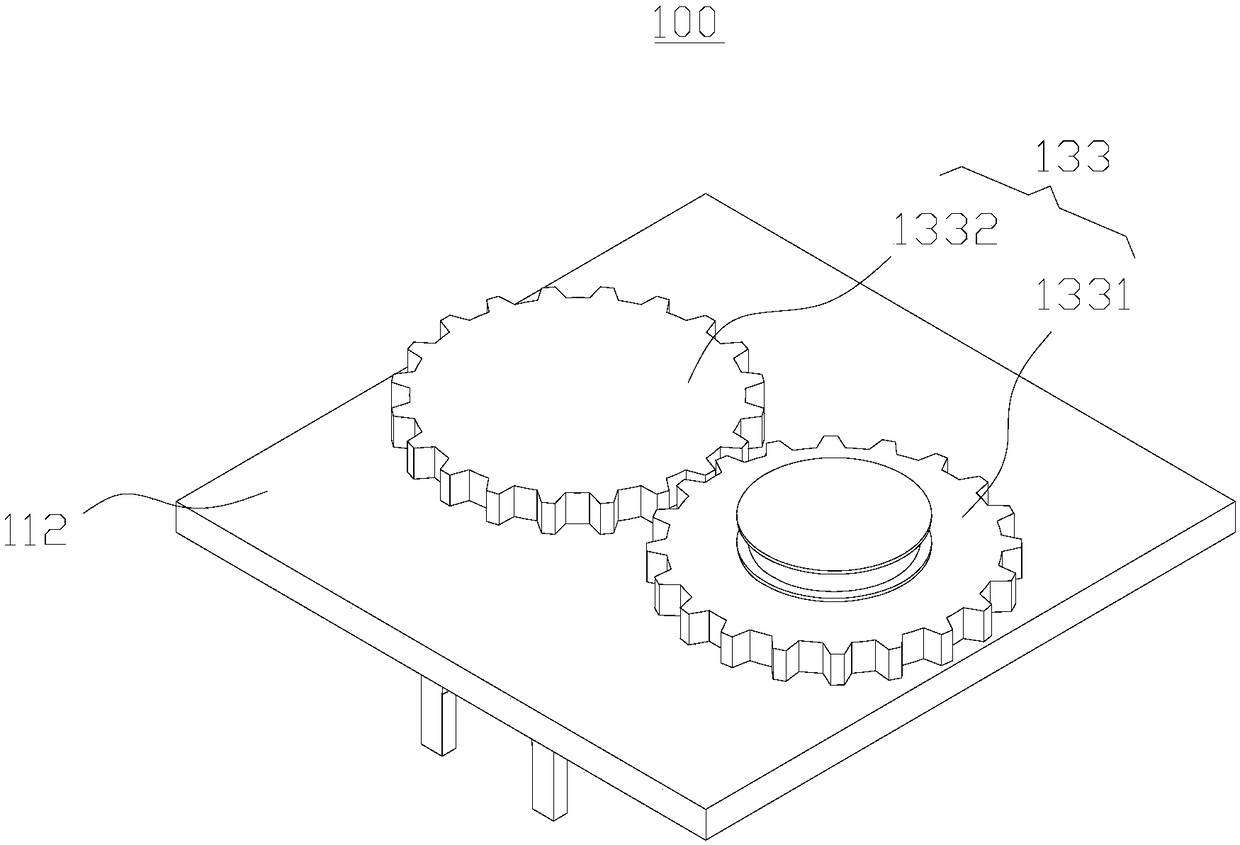

[0035] Such as figure 1 and figure 2As shown, the clamping device 120 includes a pair of clamping pieces 1201 that can approach or move away from each other, wherein each clamping piece 1201 includes a clamping arm 121 and a limiting mechanism 122 for limiting the movement of the clamping arm 121 . Each limiting mechanism 122 includes a limiting slot 1221 on the installation platform 110 and a connecting piece 1222 slidingly matched with the limiting slot 1221 . The limiting groove 1221 is annular, and one end of the connecting member 1222 is slidably embedded in the limiting groove 1221 , and the other end is connected to the clamping arm 121 . At the same time, each clamping part 1201 includes a driving device 130 for driving the connecting part 1222 to move along the...

no. 2 example

[0042] This embodiment provides a pipe cutting device 10, referring to Figure 5 As shown, a cutting device 200 and an intermittent clamping and feeding device 100 are included.

[0043] Such as Figure 5 As shown, the cutting device 200 includes a cutting frame 210 , and a cutting knife 220 and an extruding block 230 mounted on the cutting frame 210 . A cutting chamber 223 for placing pipes is formed between the cutter 220 and the extruding block 230 . The cutting is completed by intermittently clamping and feeding the tubular material into the cutting cavity 223 between the feeding device 100 .

[0044] In this embodiment, the tubular material is cut off by shearing between the cutter 220 and the extruding block 230 . Further, the side of the cutting knife 220 facing the extruding block 230 is bent into a "V" shape in a direction away from the extruding block 230 , forming a first cutting knife 221 and a second cutting knife 222 at a certain angle. During actual shearing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com