Novel rail-guided intelligent assembly vehicle

A technology for assembling trolleys and new guide rails, applied in transportation and packaging, mechanical conveyors, conveyors, etc., can solve the problems of RGV trolleys being unable to freely enter the assembly line of the assembly line, lack of detection and protection functions, and insufficient personnel protection. Reliability advantage, high reliability, long service life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

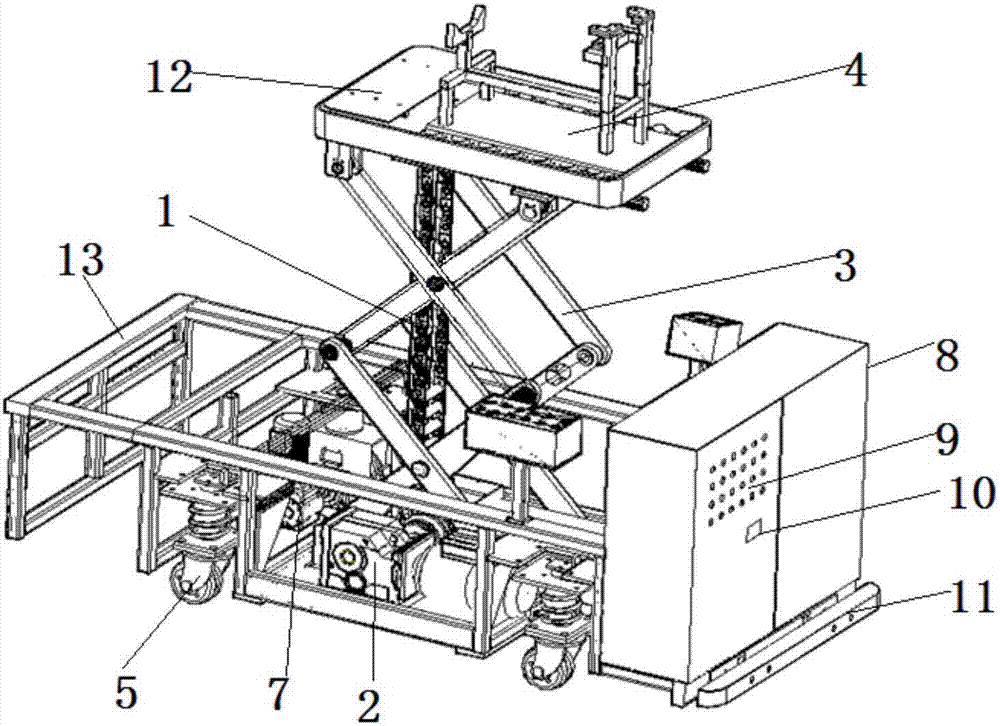

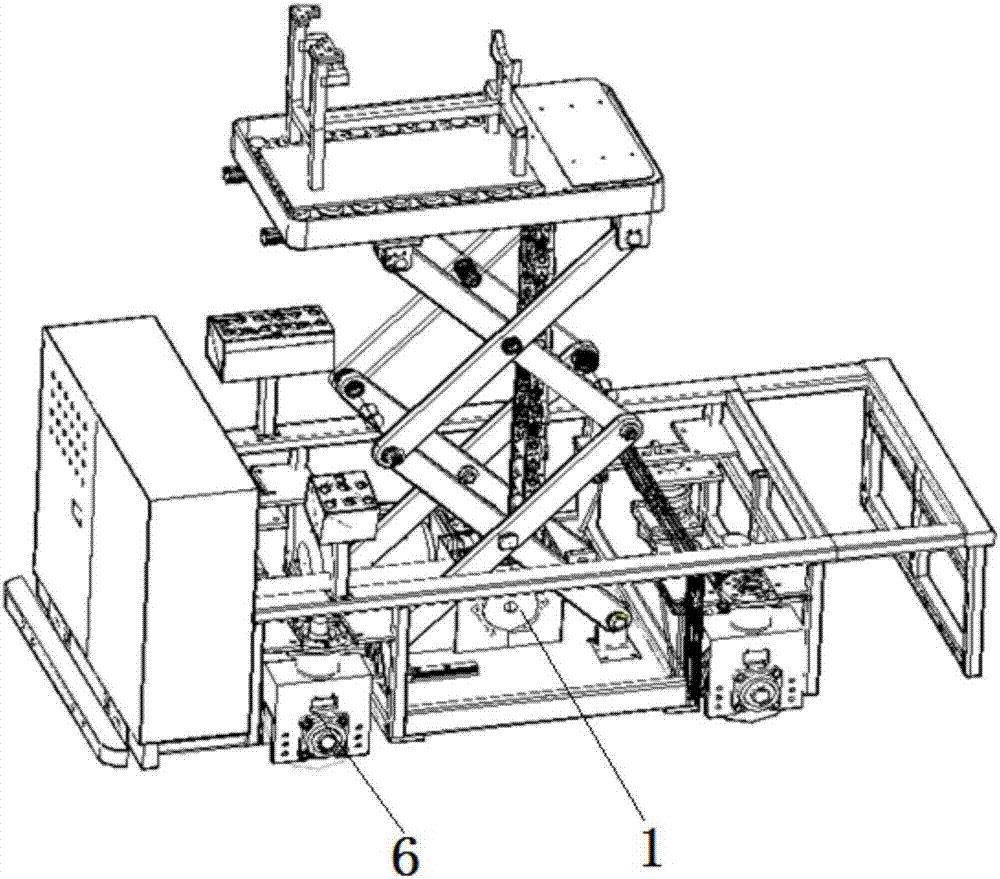

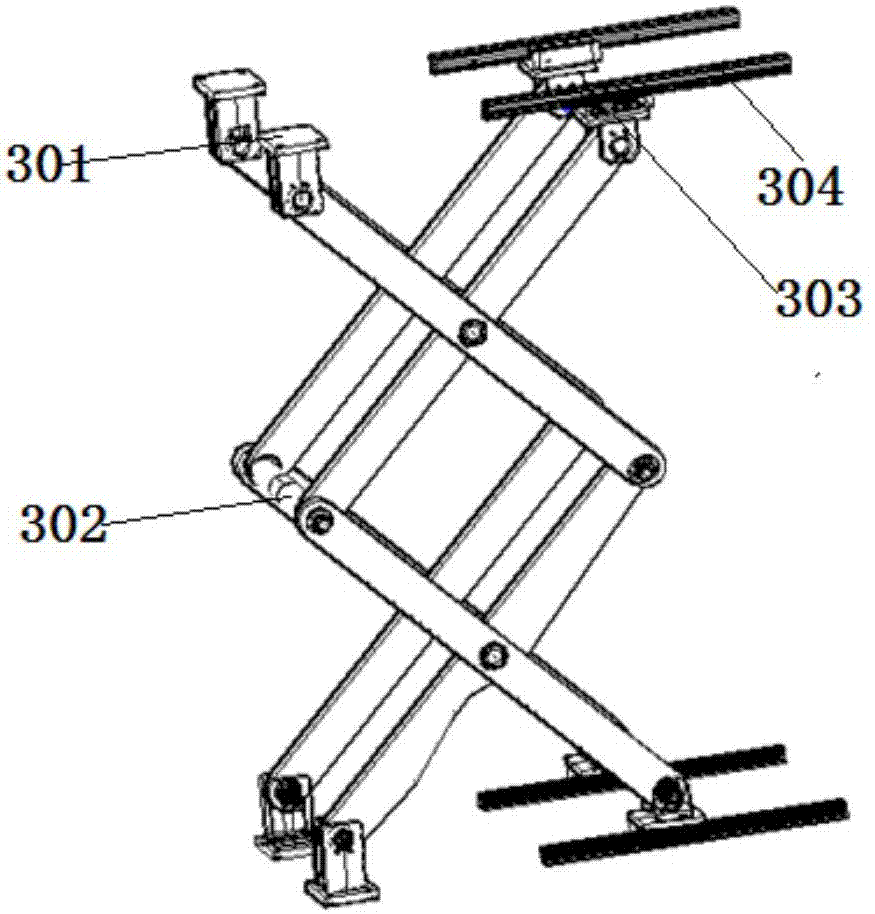

[0025] Such as figure 1 and figure 2 As shown, the present invention includes a base 13, a rigid chain lifting device arranged on the base, a pallet 4 arranged above the rigid chain lifting device, and shears for balancing the pallet 4 arranged on both sides of the rigid chain lifting device. Frame 3 and tray 4 are provided with brackets for supporting auto parts such as engines. It also includes a protective device for protecting the new guide rail intelligent assembly trolley, running wheels 5 and 6 arranged under the base, and a traveling motor 7 for driving the running wheels 5 and 6 to travel.

[0026] In addition, a control system 8 is also provided at one end of the base 13, and the control system is provided with a two-way wireless IO module for controlling the new guide rail intelligent assembly trolley. Through a standard two-way ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com