Method for producing novel rubber protecting wax

A rubber protective wax, a new type of technology, applied in petroleum wax recovery, petroleum wax refining, hydrocarbon oil treatment, etc., can solve the problems of low product yield and long production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

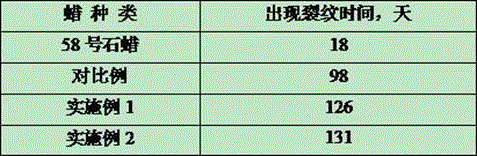

Examples

Embodiment 1

[0059] This embodiment includes: A sweating and B deployment.

[0060] A: sweating

[0061] This part includes: (A1) preparation work, (A2) crystallization, (A3) sweating, (A4) refining and other processes.

[0062] (A1) Preparations

[0063] Connect the jacket of the sweating dish and the movable coil to the circulation system, and fix the coil on the sweating dish; use water as the medium; start the heating function of the circulation system to raise the temperature of the circulating water to 70°C.

[0064] Put water under the sweating dish plate. Install the sealing system on the upper part of the sweating dish and connect it with the pressurized buffer tank and the compressor; install the decompression buffer tank on the lower part of the sweating dish and connect the vacuum pump; start the compressor and keep the pressure in the pressurized buffer tank stable at 3.2 to 3.4 atmospheres (Gauge).

[0065] to 66 # Crude paraffin (Gaoqiao Petrochemical Company, melting p...

Embodiment 2

[0077] This embodiment includes: A sweating and B deployment.

[0078] A: sweating

[0079] This part includes: (A1) preparation work, (A2) crystallization, (A3) sweating, (A4) refining and other processes.

[0080] (A1) Preparations

[0081] Connect the jacket of the sweating dish and the movable coil to the circulation system, and fix the coil on the sweating dish; use water as the medium; start the heating function of the circulation system to raise the temperature of the circulating water to 70°C.

[0082] Put water under the sweating dish plate. Install the sealing system on the upper part of the sweating dish and connect it to the pressurized buffer tank and the compressor; install the decompression buffer tank on the lower part of the sweating dish and connect it to the vacuum pump; connect the pressurized buffer tank emptying system and the exhaust port of the lower part of the sweating dish to the absorption The system is connected well, with 5% NaOH solution as th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com