Method for improving oxidation ablation resistant performance of material based on surface micro-structure modifying

A technology of ablation performance and anti-oxidation, applied in the coating process and coating of metal materials, etc., can solve the problems of easily damaging the matrix material, aggravating the degree of material ablation, etc., so as to reduce the final thickness and improve the anti-oxidative ablation performance. , the effect of strong adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further elaborated below through specific embodiments in conjunction with the accompanying drawings.

[0033] A. Polish the surface of the substrate to make the surface of the substrate clean and dry. Put the aqueous solution of aluminum dihydrogen phosphate with a concentration of 75% in a beaker, put it into a vacuum box to evacuate, and extract the gas in the solution. Then the vacuumized aluminum dihydrogen phosphate solution is coated on the substrate surface.

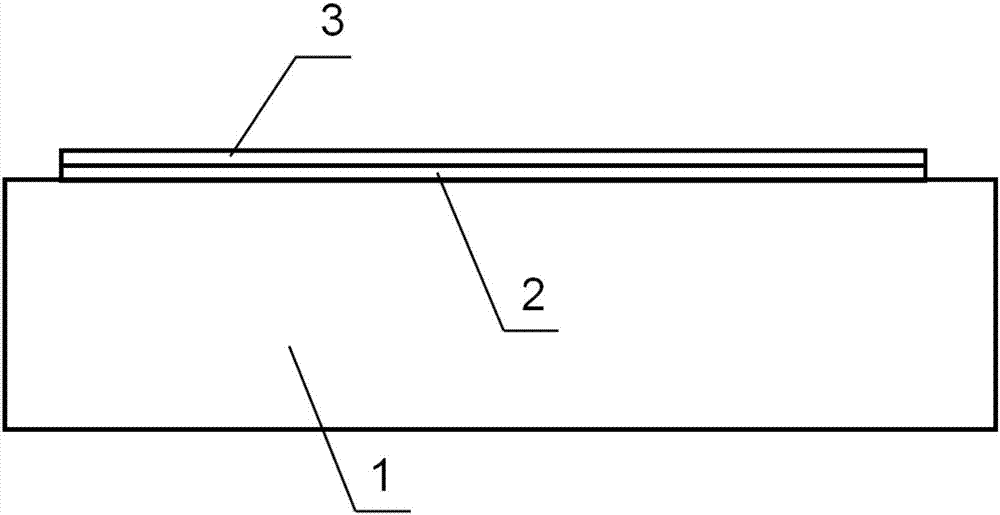

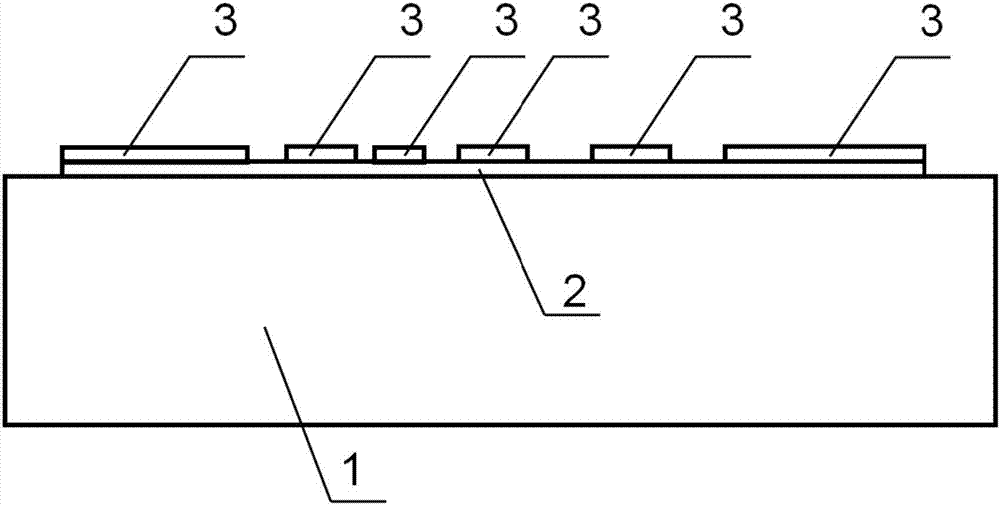

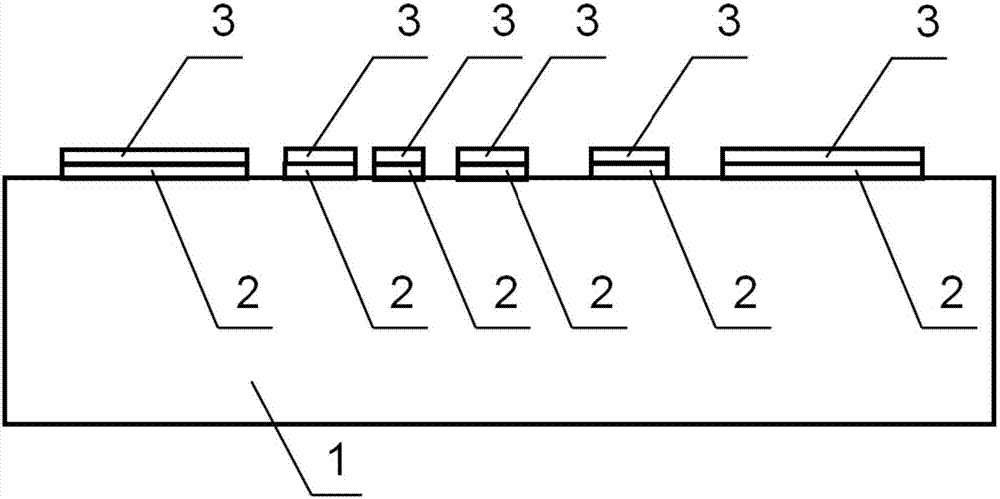

[0034] B. Put the substrate coated with aluminum dihydrogen phosphate into a vacuum heating oven and dry it at 35°C-45°C until the liquid evaporates completely, and the aluminum dihydrogen phosphate becomes solid and sticks to the surface of the substrate. At this point, the photoresist is coated on the surface of aluminum dihydrogen phosphate, and the obtained microstructure schematic diagram is as follows figure 1 as shown, figure 1 It includes substrate 1, aluminum dihyd...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com