Composite floor construction method

A construction method and flooring technology, applied in the processing of building materials, floors, buildings, etc., can solve the problems of easy wear and tear of tiles, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

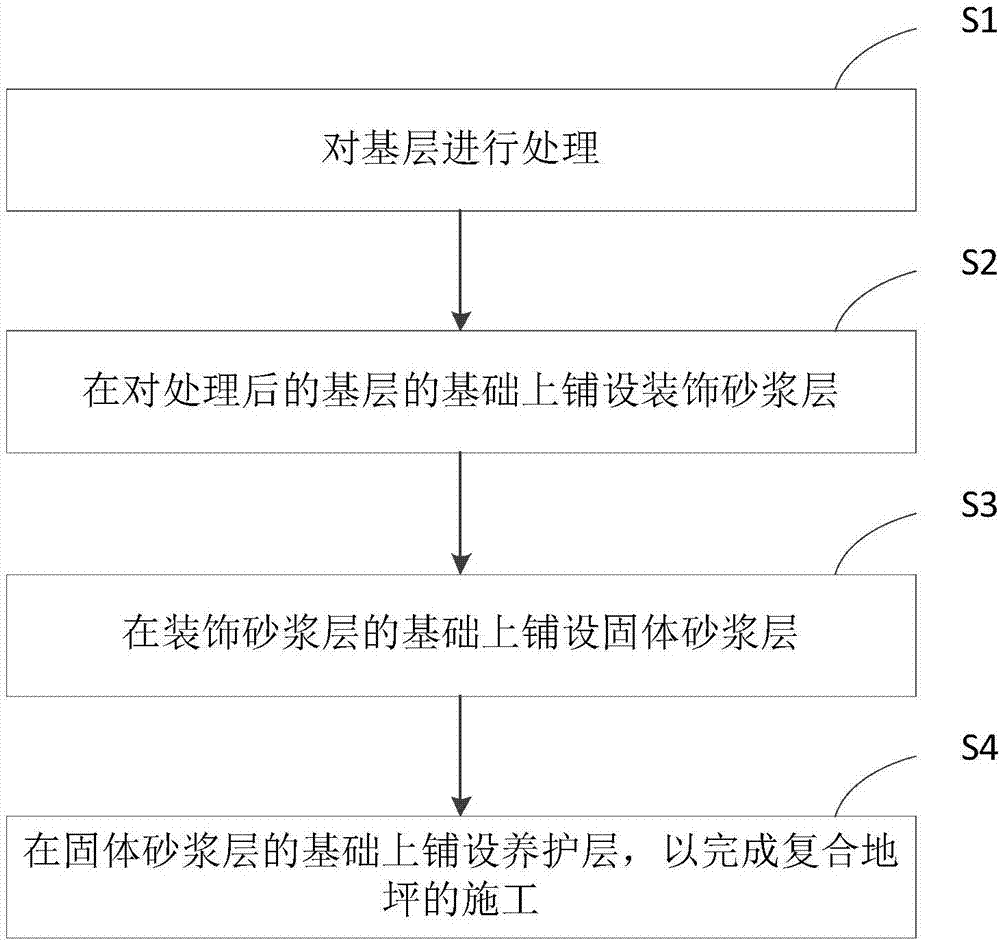

[0051] Embodiment 1 of the present invention discloses a construction method of a composite floor, which is applied to the surface of a concrete base, such as figure 1 As shown, the construction method includes:

[0052] Step S1, processing the base layer;

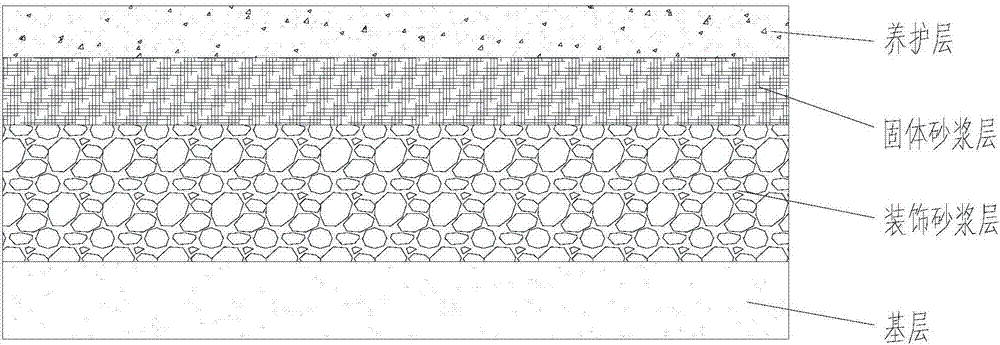

[0053] Step S2, laying a decorative mortar layer on the basis of the treated base;

[0054] Step S3, laying a solid mortar layer on the basis of the decorative mortar layer;

[0055] Step S4, laying a curing layer on the basis of the solid mortar layer to complete the construction of the composite floor.

[0056] In a specific embodiment, step S1 specifically includes the following steps:

[0057] Step S11, removing all the original cement self-leveling layers on the old and new concrete bases;

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com