Process for machining cold-forging plunger latch head

A processing technology and latch technology, which is applied in the processing field of lock heads, can solve the problems of size, concentricity and parallelism, inconsistency between brightness and chamfering, affecting product quality and output, size, and brightness instability, etc. Eliminate machining time and processing machinery costs, improve yield and quality, and achieve considerable results in materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

[0031] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

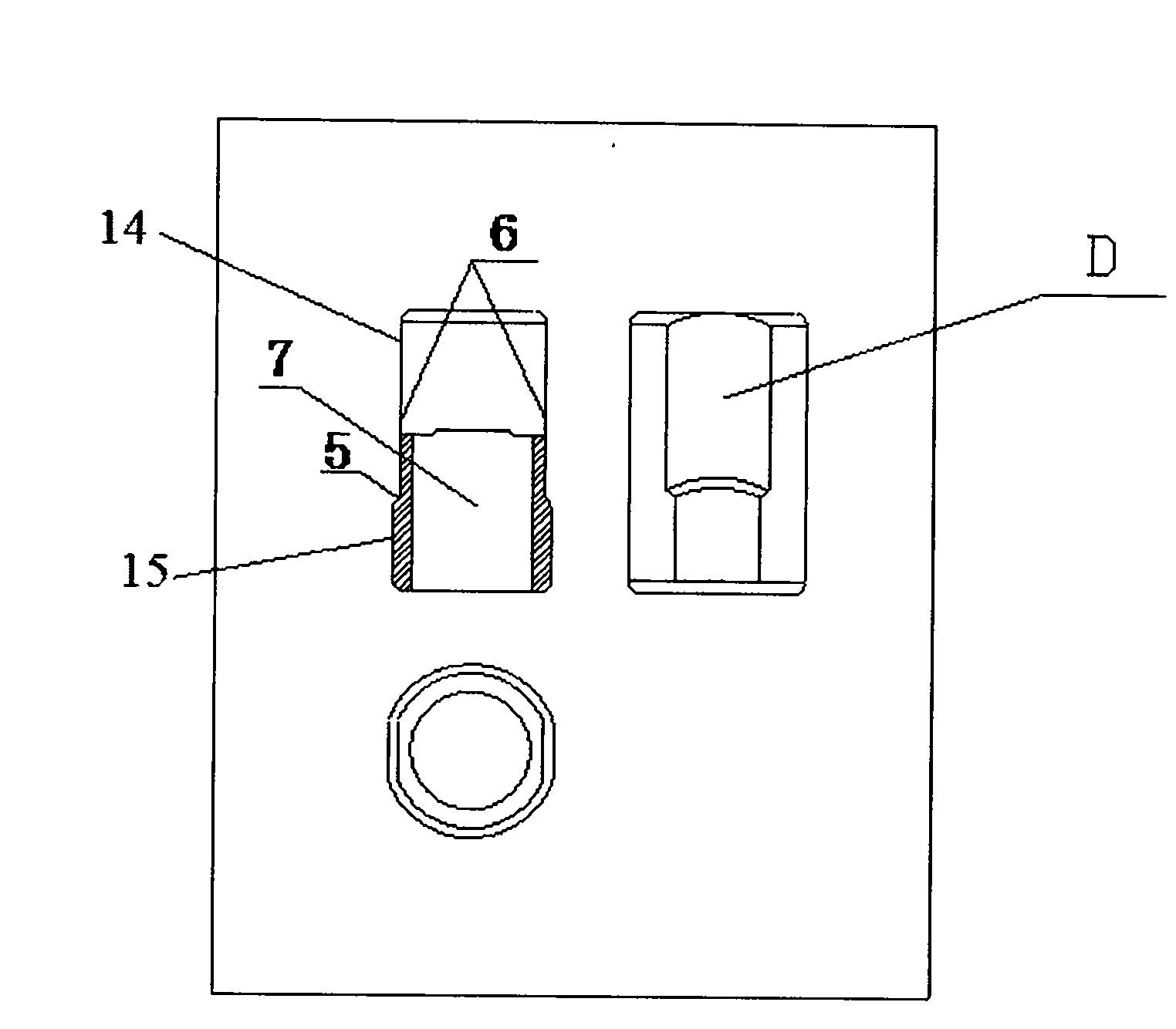

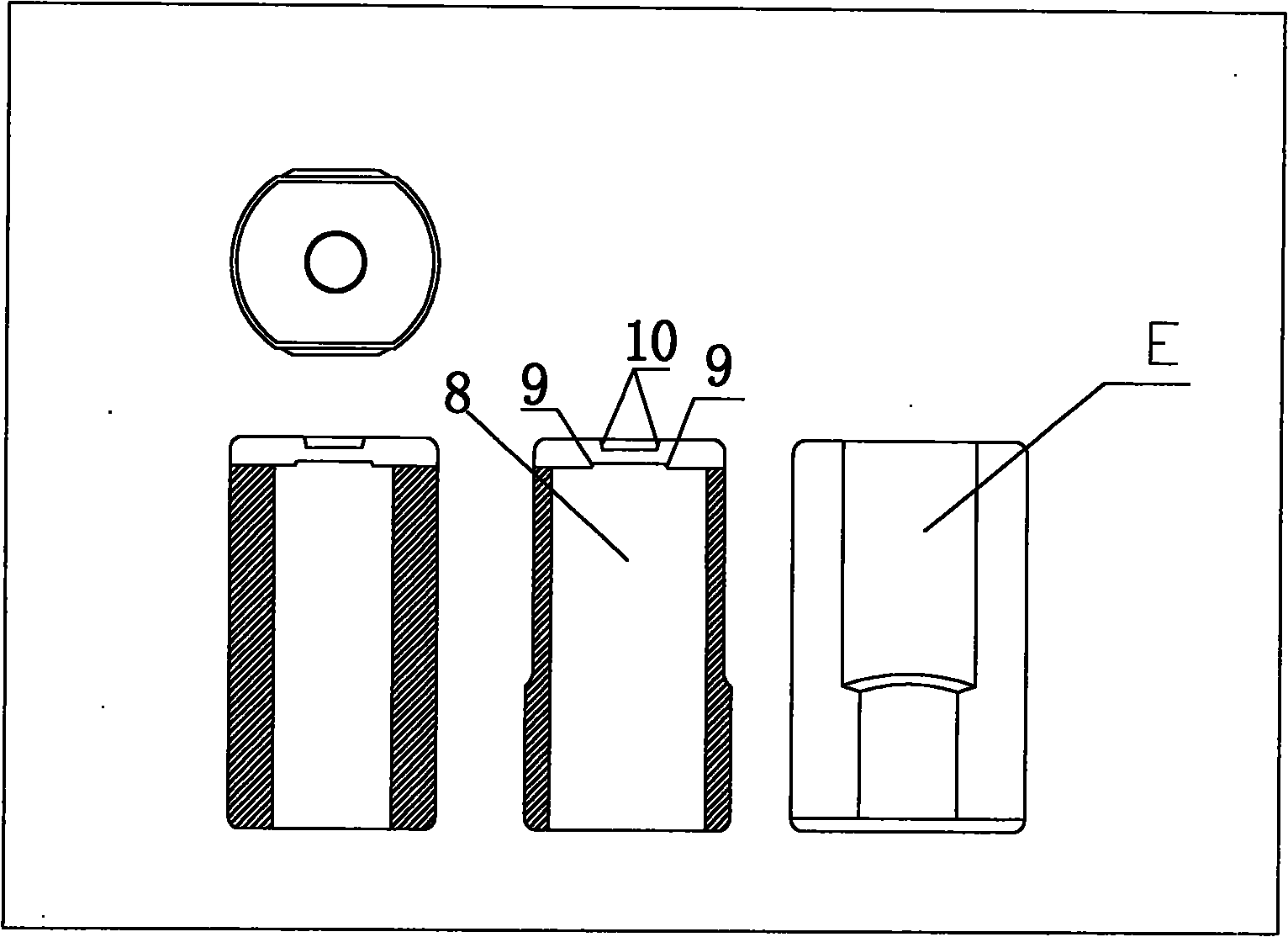

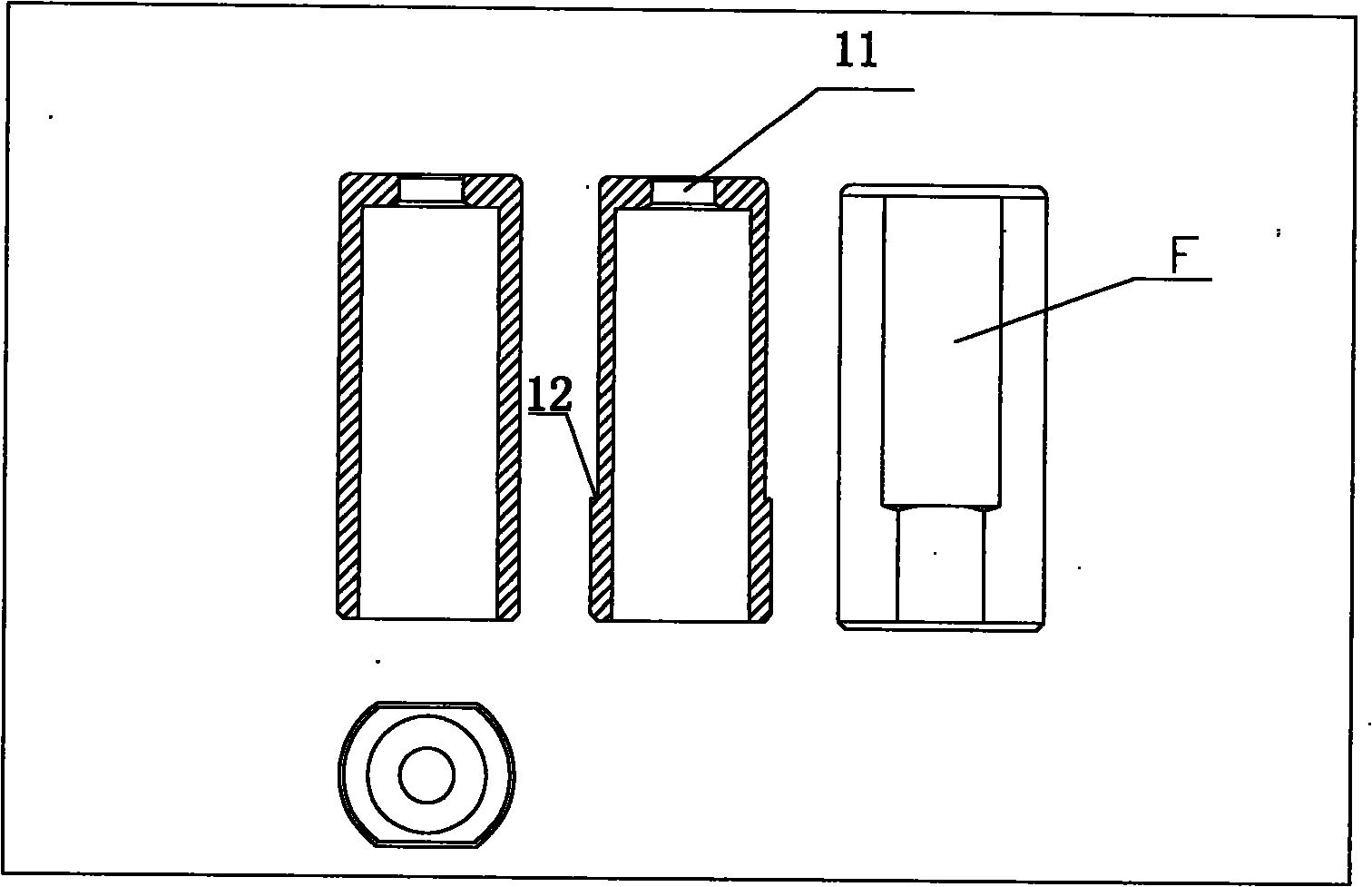

[0032] see Figure 9 : the present invention's lock bolt head processing technology has adopted a multi-station cold forging machine, and comprises the following steps: (1) cutting material; (2) extruding chamfering; (3) extruding flat shape and chamfering; (4) ) beam flattening and inner hole stretching; (5) stretching and inner and outer chamfering; (6) bottom small hole punching and step extrusion; (7) small hole punching on both sides.

[0033] In this implementation, the processing technology of the bolt head of the lock of the utility model mainly completes the manufacture of the bolt head through the foll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com