Aluminum-coated plastic energy-saving fire-resistant window and fire protection method thereof

A technology of fire-resistant windows and refractory materials, which is applied in fire-resistant doors, windows/doors, and door/window applications. The effect of preventing the passage of open flames and preventing collapse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

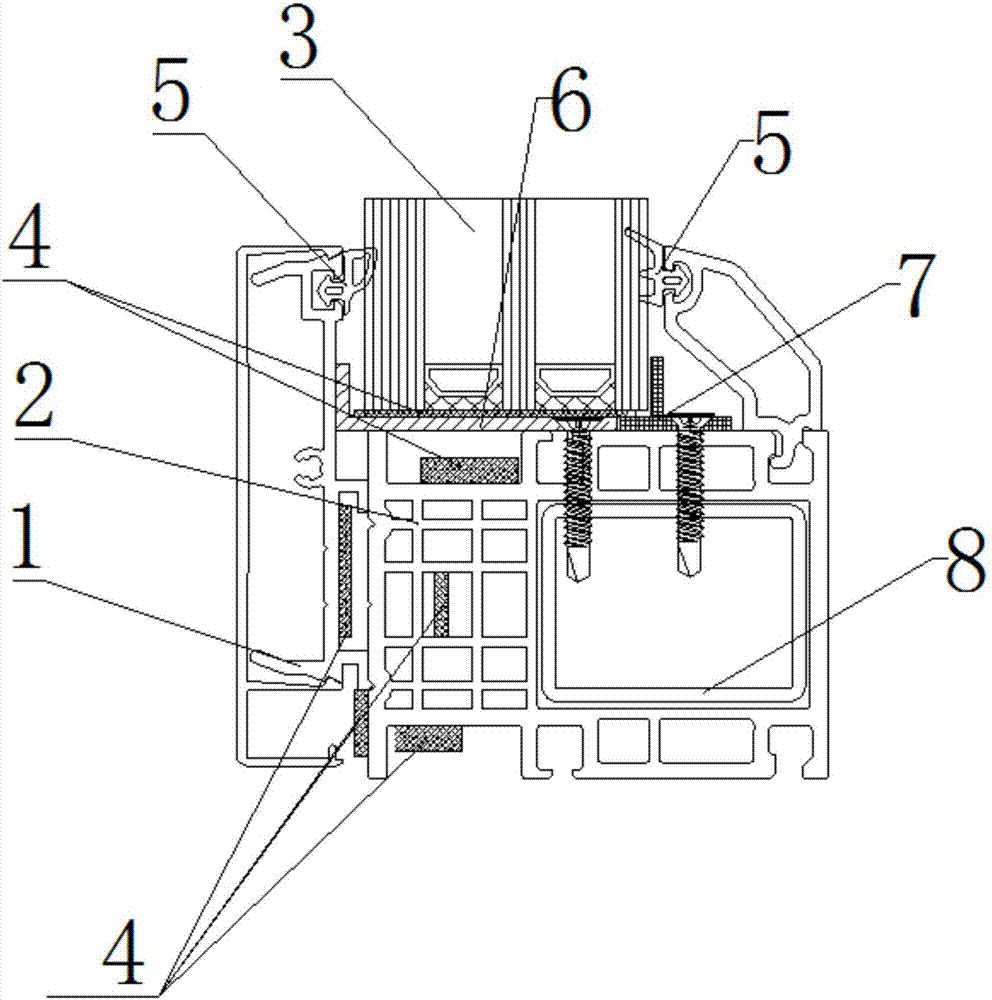

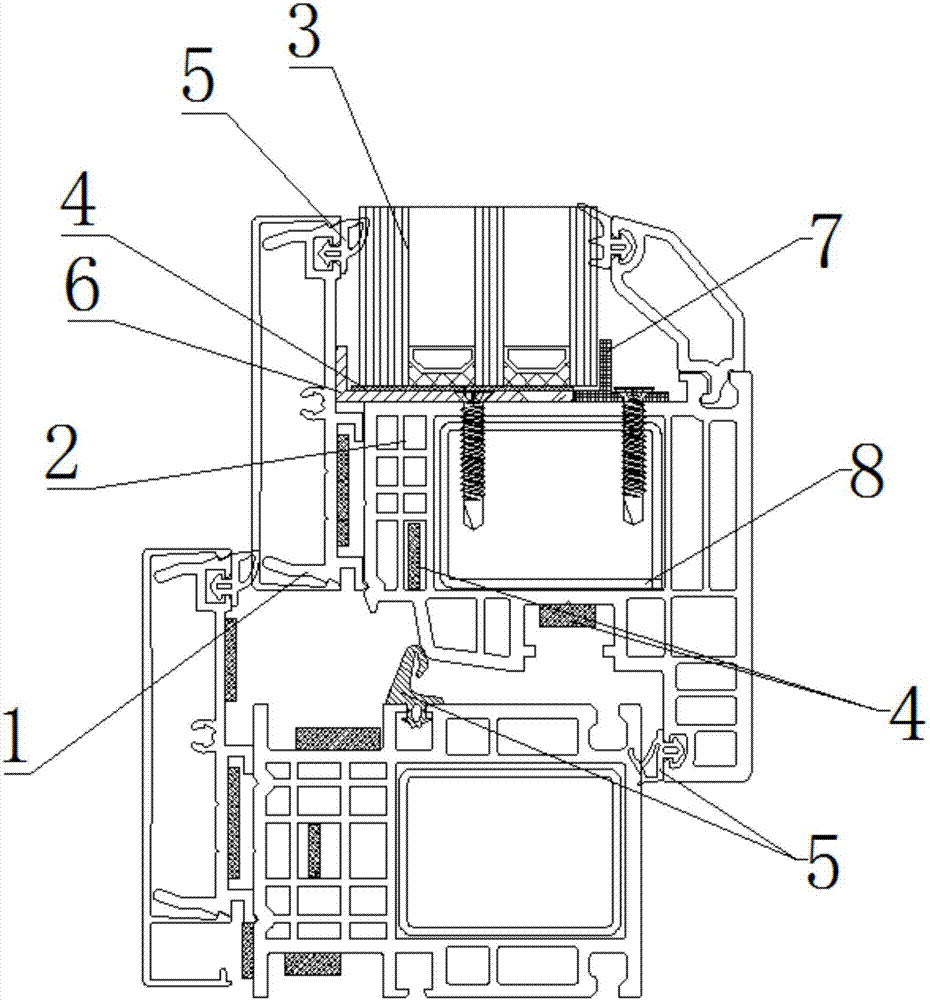

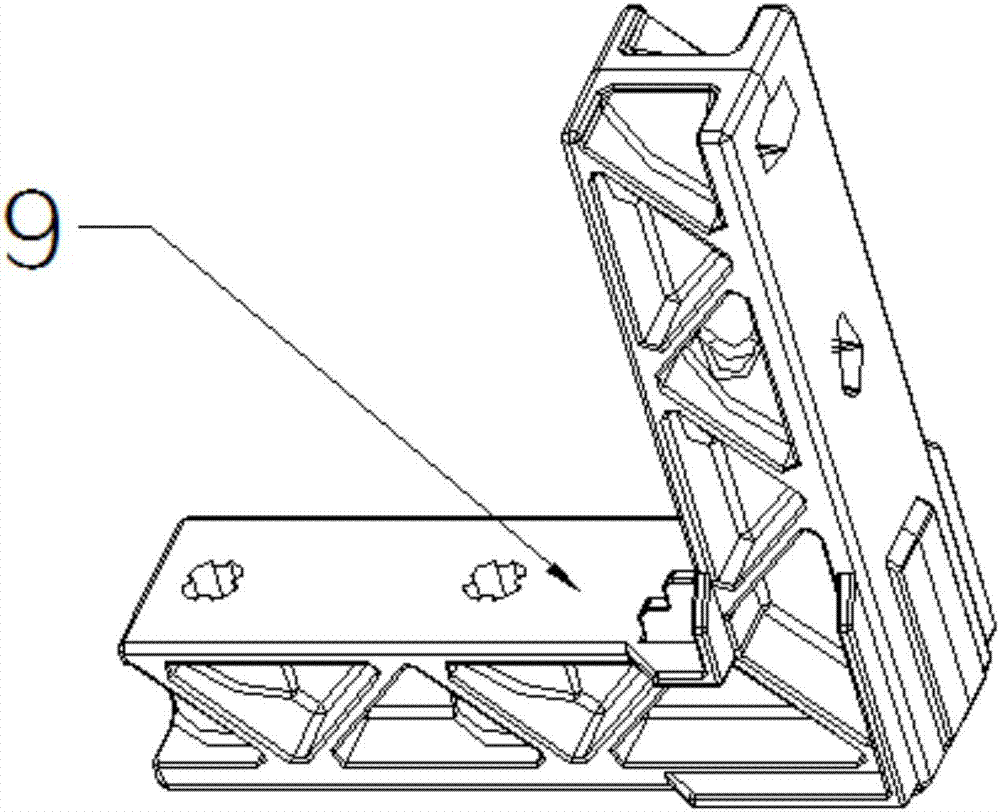

[0017] Referring to the accompanying drawings, an aluminum-coated plastic-coated energy-saving fire-resistant window of the present invention is characterized in that: the square steel 8 is fixedly installed in the chamber of the PVC profile 2, and the structural aluminum profile 1 is fixed on the PVC profile 2 and the square steel 8. A refractory material 4 is attached to the chamber of the PVC profile 2 and the outer surface of the PVC profile 2. The refractory material is an expanded graphite sealing strip. The refractory material 4 in the chamber of the PVC profile 2 is pasted before the window frame is assembled, and the refractory material on the outer surface 4 Paste after the window frame is assembled to ensure continuity. After the PVC profile 2 and the structural aluminum profile 1 are assembled, install the L-shaped glass support plate 6 on the PVC profile 2, and then paste a The refractory material 4 of the ring, the refractory material 4 covers the L-shaped glass s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com