Four-channel distribution and initiation cabinet with function of supplying air for novel protection air curtain

A four-channel, triggering cabinet technology, applied in the direction of combustion product treatment, combustion method, solid residue removal, etc., can solve problems such as corrosion of soot blowing equipment, and achieve the effect of eliminating the impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

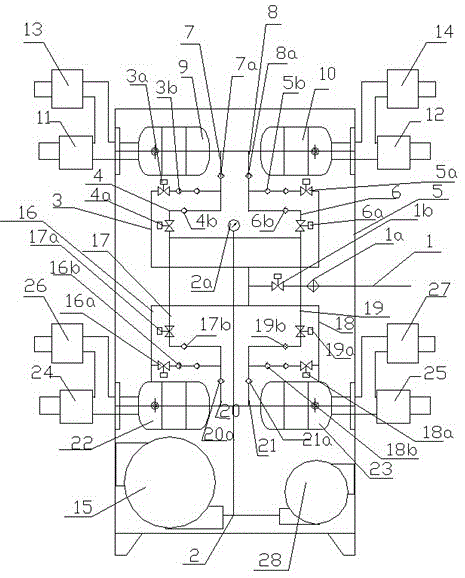

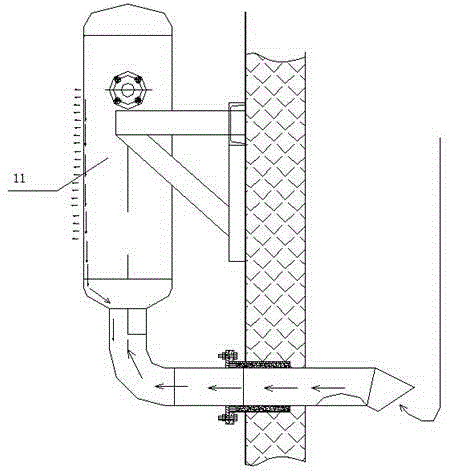

[0021] Such as figure 1 As shown, a new four-channel self-supply air supply and gas distribution induction cabinet for a new type of protective air curtain, including acetylene supply main pipe 1, air supply main pipe 2, acetylene supply branch one 3, air supply branch one 4, acetylene supply branch two 5, air supply Branch pipe two 6, acetylene supply branch pipe three 16, air supply branch pipe three 17, acetylene supply branch pipe four 18, air supply branch pipe four 19, mixed air pipe one 7, mixed air pipe two 8, mixed air pipe three 20, mixed air pipe four 21, mixed ignition Tank one 9, mixed ignition tank two 10, mixed ignition tank three 22, mixed ignition tank four 23, pulse generator one 11, pulse generator two 12, pulse generator three 26, pulse generator four 27, the acetylene Supply main pipe 1 is connected with acetylene supply branch pipe one 3, acetylene supply branch pipe two 5, acetylene supply branch pipe three 16, acetylene supply branch pipe four 18, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com