Anti-cavitation device and construction method for hydraulic structures

A technology for hydraulic structures and construction methods, applied in construction, protection devices, water conservancy projects, etc., can solve the problems of unavoidable cavitation damage, aggravated cavitation and cavitation, and prone to cracking, etc. The effect of low construction difficulty and easy batch processing and production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

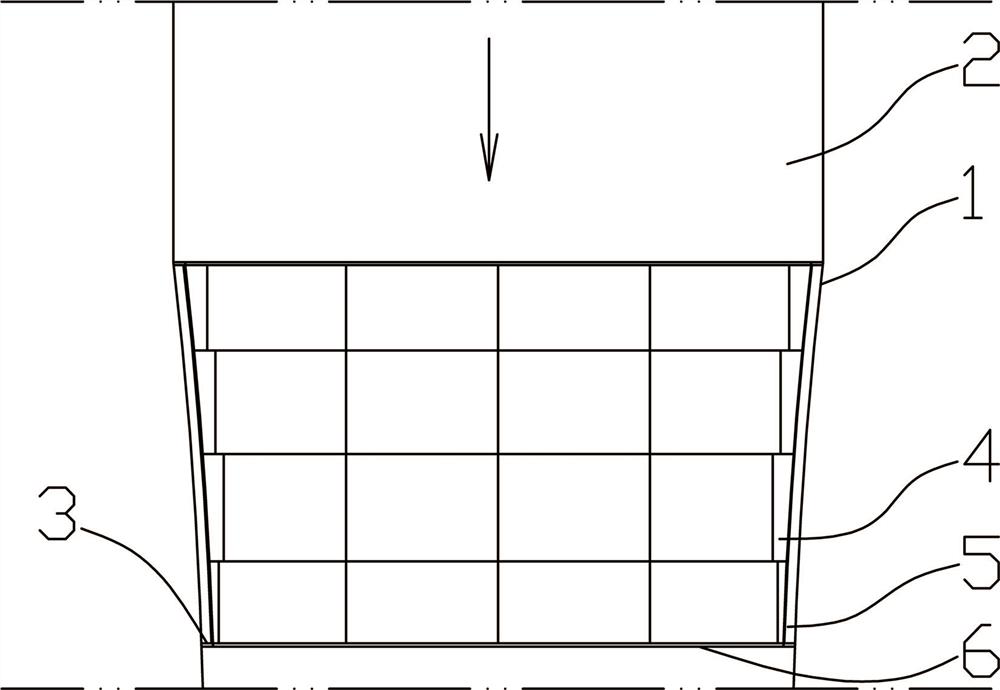

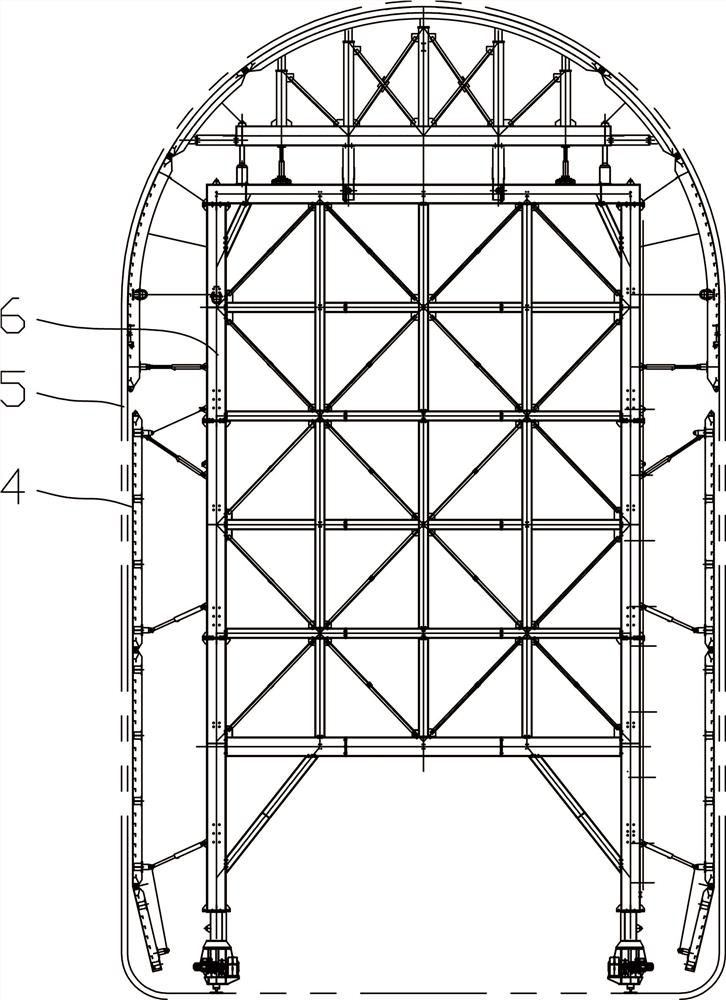

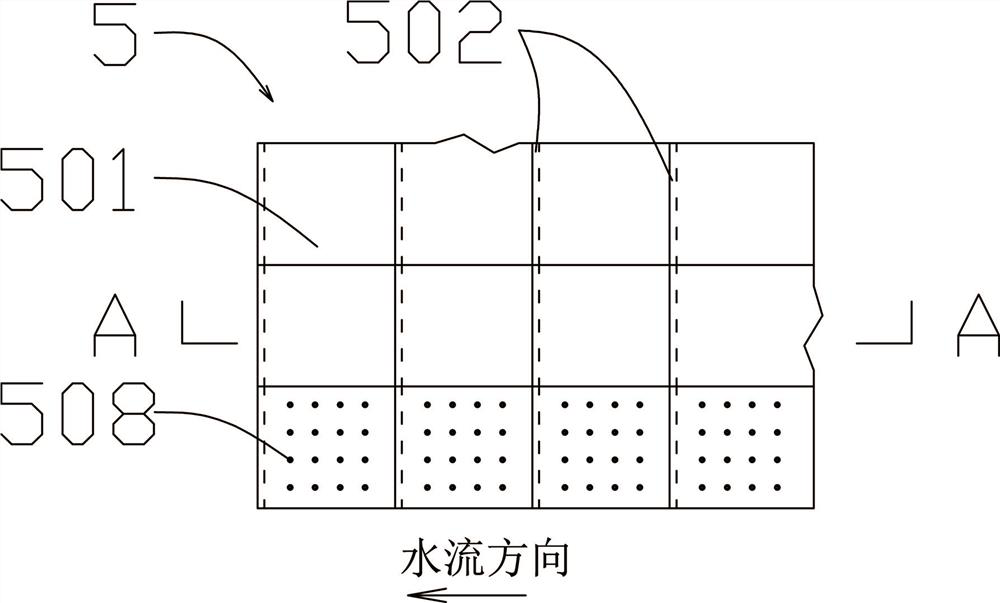

[0037] as Figure 1 、 3 , 4, a hydraulic building air defense erosion device, air defense corrosion device 5 includes a fixed frame 504 embedded in concrete, fixed frame 504 is connected to the bearing layer 506, air defense erosion panel 501 is fixedly connected to the bearing layer 506. Thus the structure, so that the air defense erosion panel 501 is reliably fixed to the inner wall of the hydraulic tunnel 2, to alleviate the cavitation damage at this location.

[0038] Preferred schemes such as Figure 4 In, the air defense corrosion panel 501 is a cavitation-resistant alloy material, including a stainless steel material or titanium alloy material. When the overcurrent flow rate is less than 14m / s. For example, when the overcurrent flow rate is 8m / s, a smooth and flat defect-free cavitation-resistant alloy material is used, and a titanium alloy material is preferred in this example. The bearing layer 506 adopts a polymer material with certain elasticity. For example, ultra-high m...

Embodiment 2

[0048] as Figure 1 、 2 , one of the above-described construction methods of the hydraulic building anti-aircraft erosion device, comprising the following steps:

[0049] S1, in the variable section section 1 select a single lining trolley 6, the lining trolley 6 according to the preset hydraulic tunnel 2 inner wall contour shape of the template 4 vertical mold;

[0050]S2, in the lining trolley 6 template paste double-sided adhesive, the air-defense corrosion device 501 of the air-defense erosion device 501 through the double-sided adhesive bonding connection; In the preferred embodiment, when installing the anti-aircraft corrosion device 5, a steel wire is buried in the double-sided adhesive, and the steel wire is arranged along the axis direction of the variable section section 1, for cutting the double-sided adhesive with steel wire when dismantling the mold, so as to facilitate the removal of the mold.

[0051] S3, the fixed frame 504 of the anti-corrosion device 5 is fixed by...

experiment example 1

[0061] On the overcurrent section side of the variable section section 1 with an overcurrent flow rate of 8m / s, as the experimental side, the air defense corrosion device 5 arranged in the array is installed, the air defense corrosion panel 501 adopts titanium alloy material, and the bearing layer 506 adopts a polymer material with certain elasticity; On the other side is the original overcurrent section of concrete with a certain roughness, which acts as the control side. Hydrophones and high-speed cameras are used to monitor the vaping of the nascent and development of cavitation on both sides, respectively, such as Figure 6 As shown in , when cavitation is detected on the control side, no cavitation occurs on the experimental side.

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com