Method for epitaxially growing yttrium iron garnet nanometer thin film with perpendicular magnetic anisotropy

A technology of yttrium iron garnet and epitaxial growth, which is applied in the field of anisotropy regulation of magnetic materials, can solve the problems of simultaneously realizing nanometer thickness and perpendicular magnetic anisotropy, and achieve the effect of high induced magnetic anisotropy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

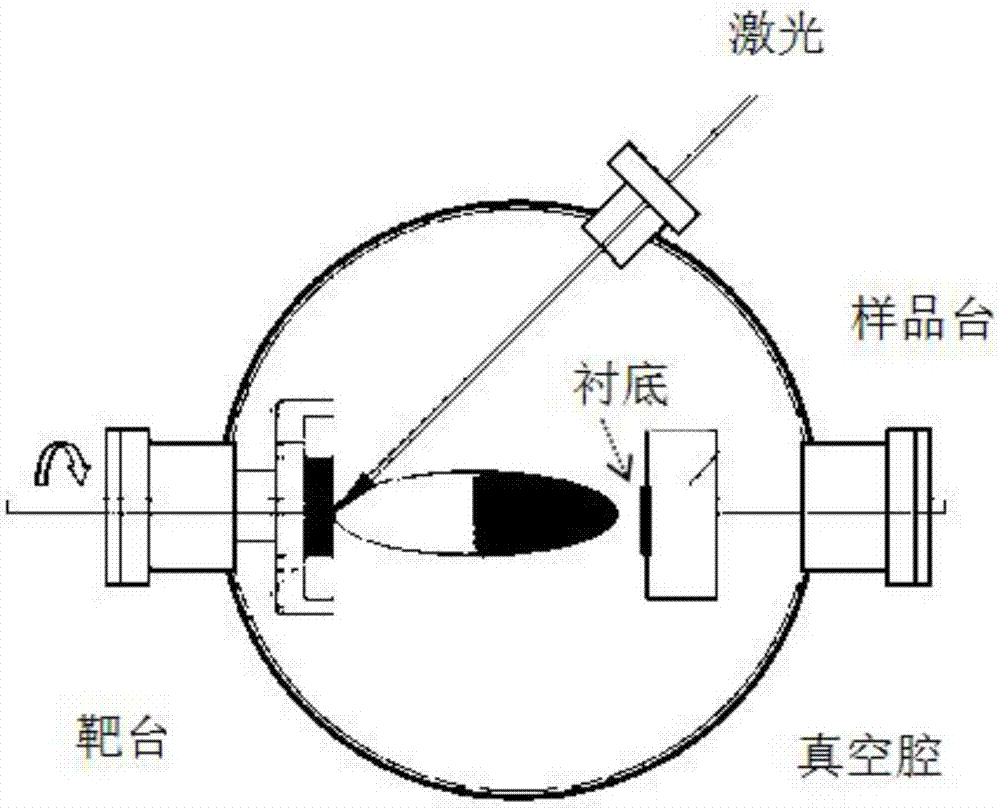

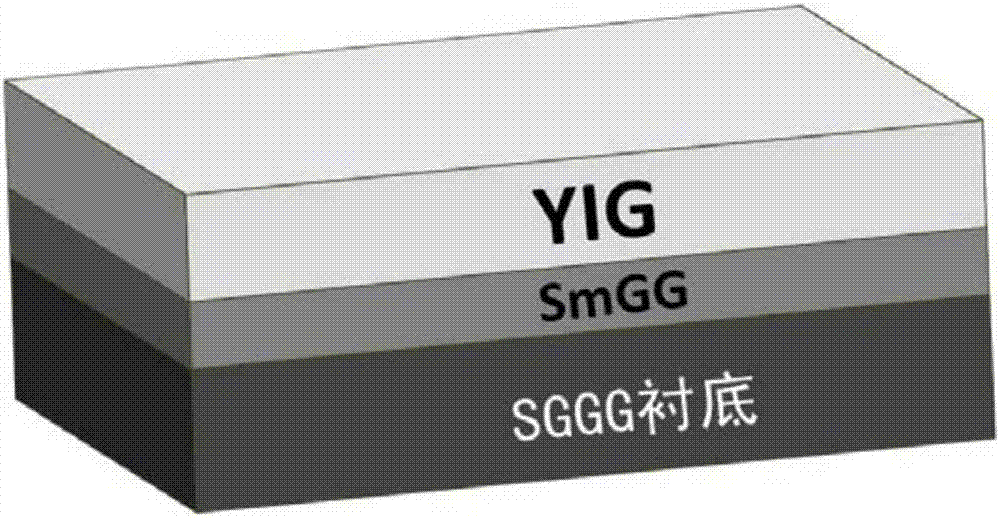

[0029] The steps adopted in this embodiment are as follows:

[0030] 1. Preparation of high-purity yttrium iron garnet (Y 3 Fe 5 o 12) and samarium gallium garnet (Sm 3 Ga 5 o 12 ) target. Set the distance between the target and the substrate as 6cm (this distance will affect the deposition rate). Place the SGGG substrate in a vacuum better than 4×10 -4 Pa vacuum chamber heated to 800-900 ℃ pretreatment.

[0031] 2. Fill the vacuum chamber with high-purity oxygen and adjust the air pressure to 20Pa;

[0032] 3. Under the condition that the substrate is 800-950°C, adjust the laser energy density to about 1.8J / cm 2 , with a pulse frequency of 6 Hz, using a focused pulsed laser beam to bombard a pre-fired samarium gallium garnet target to deposit a buffer layer. The growth thickness of the buffer layer was controlled to 2.5 nm by the number of laser pulses. In-situ annealing was performed for 30 minutes after deposition.

[0033] 4. Under the same conditions as in the...

Embodiment 2

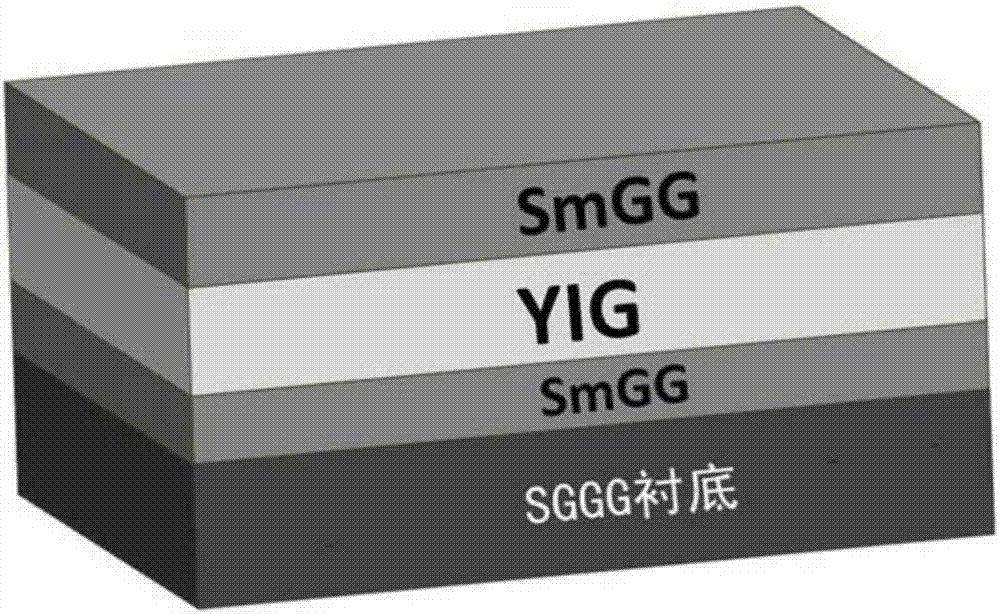

[0037] The steps adopted in this embodiment are as follows:

[0038] 1. Preparation of high-purity yttrium iron garnet (Y 3 Fe 5 o 12 ) and samarium gallium garnet (Sm 3 Ga 5 o 12 ) target. Set the distance between the target and the substrate as 6cm (this distance will affect the deposition rate). Place the SGGG substrate in a vacuum better than 4×10 -4 Pa vacuum chamber heated to 800-900 ℃ pretreatment.

[0039] 2. Fill the vacuum chamber with high-purity oxygen and adjust the air pressure to 20Pa;

[0040] 3. Under the condition that the substrate is 800-950°C, adjust the laser energy density to ~2J / cm 2 , with a pulse frequency of 6 Hz, using a focused pulsed laser beam to bombard a pre-fired samarium gallium garnet target to deposit a buffer layer. The growth thickness of the buffer layer was controlled to 2.5 nm by the number of laser pulses. In-situ annealing was performed for 30 minutes after deposition.

[0041] 4. Under the same conditions as the previous...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com