Method for preparing double-faced growth efficient wide-spectrum absorption multi-junction solar cell

A multi-junction solar cell, double-sided growth technology, applied in circuits, electrical components, final product manufacturing, etc., can solve the problems of material chip warpage, large series resistance, and reduced chip success rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

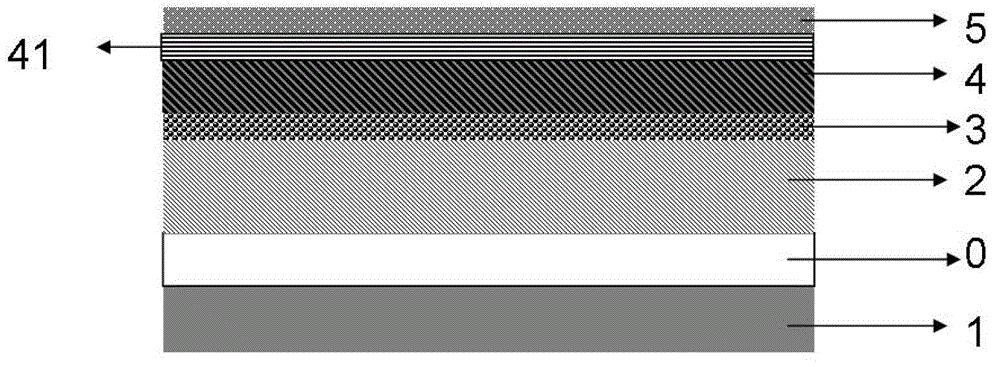

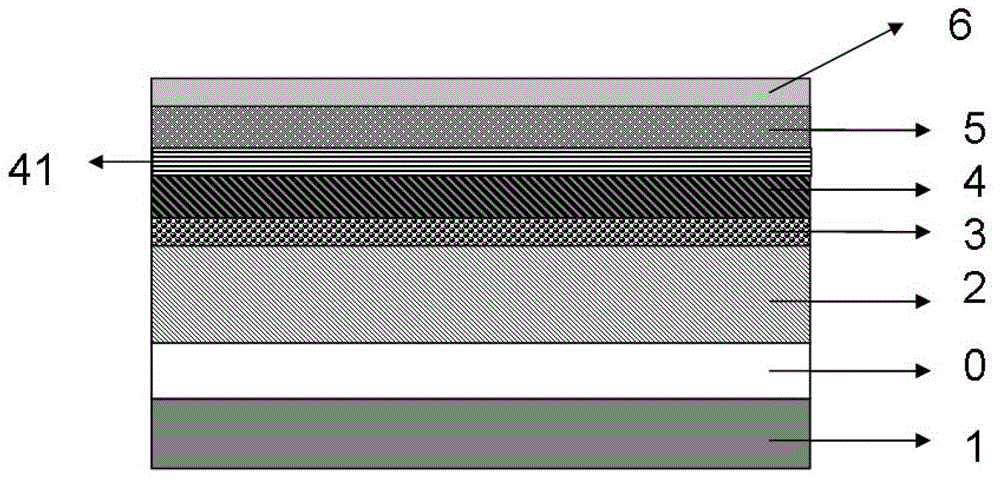

[0028] As mentioned above, the inventor in this case aims to provide a high-efficiency and broad-spectrum absorption multi-junction solar cell manufacturing process to address the shortcomings of the existing multi-junction solar cell manufacturing process. In a nutshell, the present invention applies nanopatterning technology to the epitaxy of GaAs-based InP materials (the lattice mismatch of the two reaches 3.81%, the thermal mismatch is small, and both are zinc blende cubic structures) (GaAs thermal expansion coefficient 5.73 *10 -6 ℃ -1 , InP thermal expansion coefficient 4.6*10 -6 ℃ -1 , the coefficient of thermal expansion of Si is 2.6*10 -6 ℃ -1 , the coefficient of thermal expansion of Ge is 5.9*10 -6 ℃ -1 ), and adopt a double-sided growth method in order not to affect the growth quality of each lattice matching material, so as to obtain GaInP / GaAs / InGaAsP / (InGaAs) wide-spectrum high-efficiency multi-junction cells.

[0029] Further speaking, the process of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com