Superconducting nanowire structure and preparation method thereof

A technology of superconducting nanowires and substrates, applied in the manufacture/processing of superconductor devices, nanotechnology, nanotechnology, etc., can solve the problems of superconducting nanowire damage, proximity effect of electron beam exposure, etc., to avoid contamination and the effect of etch damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026]In order to make the objectives, technical solutions and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with specific embodiments and with reference to the accompanying drawings. The following embodiments are only used to illustrate the technical solutions of the present invention more clearly, and cannot be used to limit the protection scope of the present invention.

[0027]On the one hand, the purpose of the present invention is to prepare superconducting nanowires in a bottom-up manner, adopting sidewall technology and isolating media for selective epitaxy and isolation of superconducting nanowires, and to provide a superconducting nanowire structure and its Preparation.

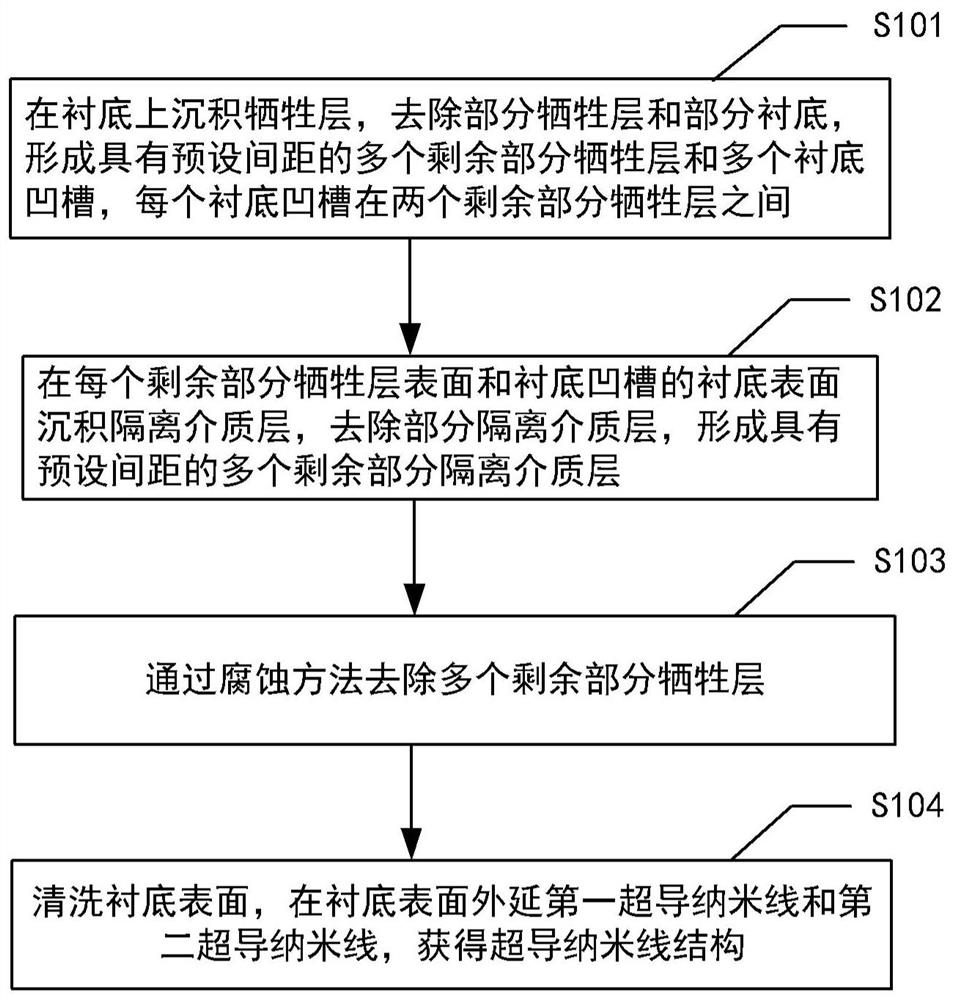

[0028]figure 1 A schematic flow chart of a method for preparing a superconducting nanowire structure according to an embodiment of the present invention is schematically shown.

[0029]Such asfigure 1 As shown, the method includes operat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com