Suction filtration purification device of benzalkonium chloride

A technology of benzalkonium chloride and liquid suction pump, which is applied in the direction of filtration and separation, gravity filter, fixed filter element filter, etc. It can solve the problems of insufficient purification, not suitable for large batches of enterprises, and liquids that cannot be removed in time. Achieve the effect of simple structure and saving cleaning agent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

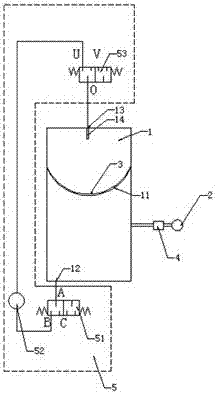

[0021] Such as figure 1 As shown, the benzalkonium chloride suction filtration purification device of the present invention is mainly composed of a cylindrical purification kettle 1 and an air pump 2, wherein a hemispherical filter with evenly distributed small round holes is fixedly installed inside the purification kettle 1. A grid frame 11, and the upper surface of the filter grid frame 11 is covered with a microporous filter membrane 3. On the side wall of the purification kettle 1, there is a ventilation hole relative to the below of the filter screen frame 11, and the ventilation hole is connected with the air inlet of the air pump 2, and the bottom of the purification kettle 1 is provided with a liquid outlet 12 that can be closed. The top cover of the purification kettle 1 is provided with an interconnected liquid inlet 13 and a spray head 14. When suction filtration and purification are required, the crystals are placed on the microporous filter membrane 3, the liquid...

Embodiment 2

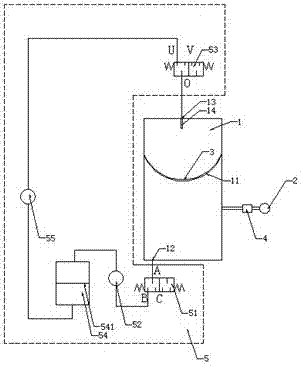

[0027] Such as figure 2 As shown, on the basis of Embodiment 1, the waste liquid circulation device 5 in this embodiment also includes a two-position three-way solenoid valve B53, a cylindrical cooling crystallization chamber 54 and a liquid suction pump B55. The liquid outlet of described suction pump A52 links to each other with the inlet that is arranged on cooling crystallization chamber 54 tops, and the outlet that is arranged on cooling crystallization chamber 54 bottoms links to each other with the liquid inlet of suction pump B55, and the liquid outlet of suction pump B55 It is connected with the U port of the two-position three-way electromagnetic valve B53, and a refrigeration device is installed inside the cooling crystallization chamber 54, and a microporous filter screen 541 is installed in the middle part. The purpose of installing a refrigeration device is to reduce the temperature of the cleaning agent, thereby reducing the solubility of impurities in it, so t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com