Barrel cover pre-coiling and glue spraying machine

A technology of glue spraying machine and barrel cover, which is applied in the direction of spraying device, other household appliances, household appliances, etc., can solve the problems of increasing the wear amount of pre-rolling molds, waste of glue liquid, and poor surface quality of curling, so as to ensure the glue spraying. Thickness, improve transfer efficiency, save operation time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

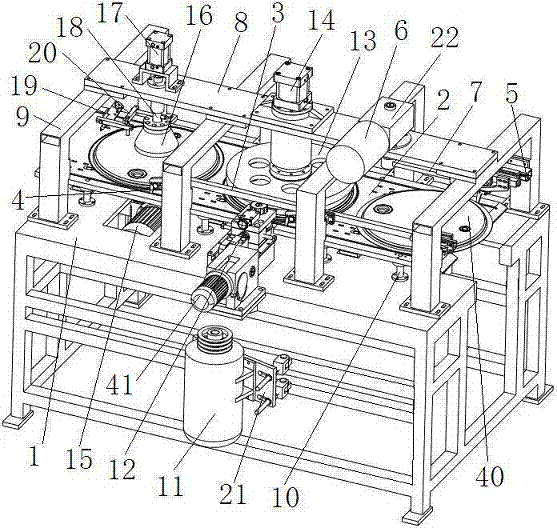

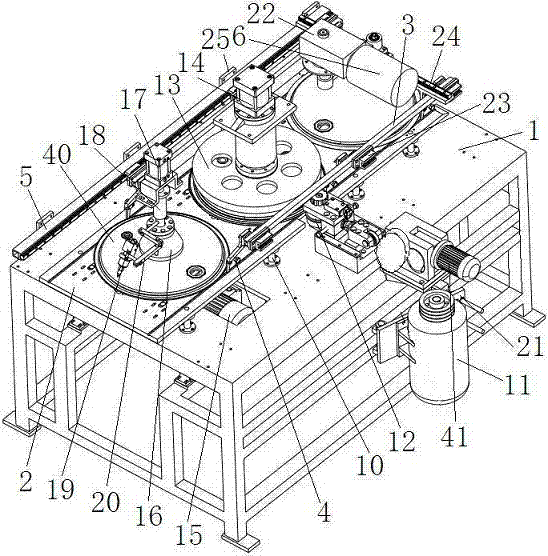

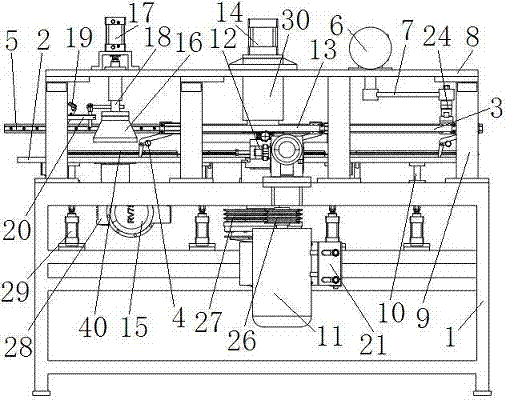

[0051] combine Figure 1~Figure 9 As shown, the present invention includes a frame 1, the top of the table top of the frame 1 is movably connected with a supporting plate 2 up and down, and the bung 40 is positioned on the top surface of the supporting plate 2 for transmission, and the supporting plate 2 is transported along the bung Direction is provided with through hole A34, through hole B35 and through hole C37 successively, and the size of described through hole A34, through hole B35 and through hole C37 is all smaller than the size of bung 40, and on described frame 1, corresponds to through hole A34 , the through hole B35 and the through hole C37 positions are respectively provided with a material preparation station, a pre-rolling station and a glue spraying station, and the top of the supporting plate 2 is provided with a transfer device for the bung 40, and the transfer device and the frame 1 The fixed frame at the top is movably connected, and the supporting plate 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com