3D printing manufacturing technology of metal porous material with through hole structure

A porous material and 3D printing technology, which is applied in metal processing equipment, additive processing, transportation and packaging, etc., can solve the problems of insufficient performance of porous materials, achieve low production cost, broad application prospects, and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

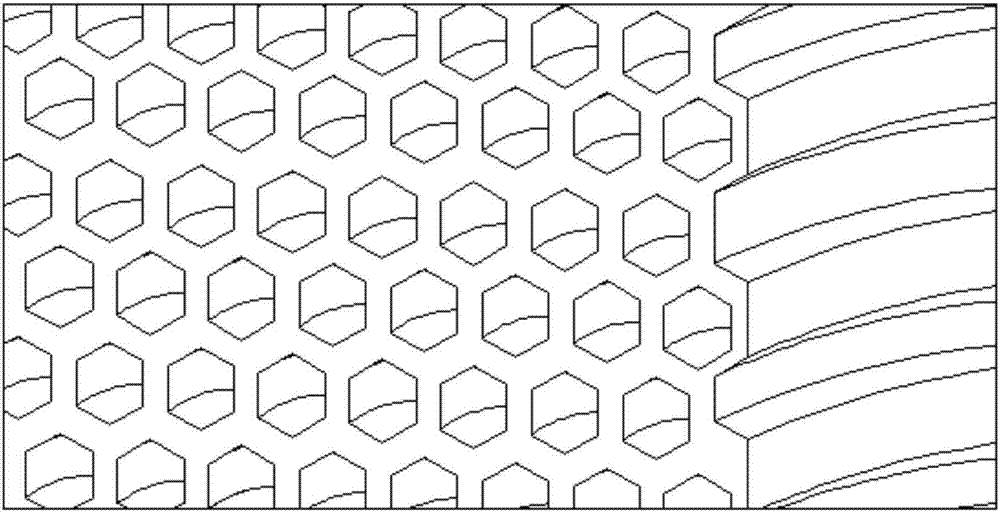

[0021] refer to figure 1 , curved channel honeycomb porous material: this type of porous material has a honeycomb structure, and the channels are curved, and the channel cross section can be of any shape;

[0022] Its 3D printing preparation process includes the following steps:

[0023] S1. Determine the specific structure and size specifications inside the curved channel honeycomb porous material, and conduct research by drawing, use the design software to carry out detailed three-dimensional design of the porous material, and draw the 3D model of the actual size porous material;

[0024] S2. According to the 3D model of the porous material made in step S1, spread the stainless steel powder into a powder layer with a thickness of 0.1 mm in the forming tank of the 3D printing device based on the principle of micro-spraying, and spray according to the solid shape of the layered cross-section of the porous material The mass percentage is 65% UV glue, 27% α-cyanoacrylate glue, ...

Embodiment 2

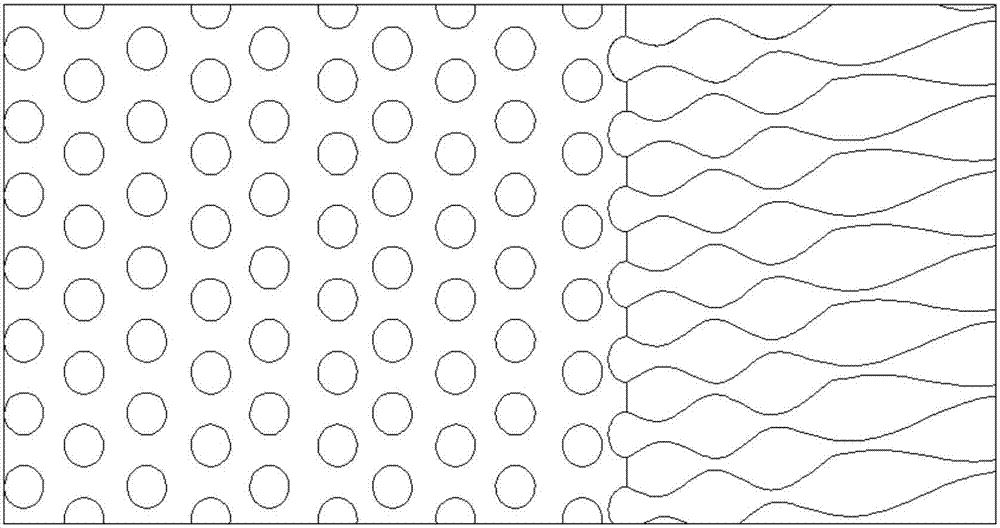

[0029] refer to figure 2 , variable cross-section honeycomb porous material: this type of porous material has a honeycomb structure, and the shape and size of the channel section are variable;

[0030] Its 3D printing preparation process includes the following steps:

[0031] S1. Determine the specific structure and size specifications inside the variable-section honeycomb porous material, and draw for research, use the design software to carry out detailed three-dimensional design of the porous material, and draw the 3D model of the actual size porous material;

[0032] S2. According to the 3D model of the porous material made in step S1, spread the mixed powder of 80% stainless steel powder and 20% carbon fiber powder into a powder with a thickness of 0.2 mm in the forming tank of the 3D printing device based on the micro-jet principle The layer is sprayed according to the solid shape of the layered section of the porous material, which is composed of 55% UV glue, 30% α-cy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com