Guiding type embedded drill bushing

An embedded and drill sleeve technology, applied in the field of machinery, can solve problems such as inability to assemble parts, difficult positioning, and deviation of drilling direction, and achieve the effects of improving assembly accuracy, simple structure, and accurate positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in combination with specific embodiments.

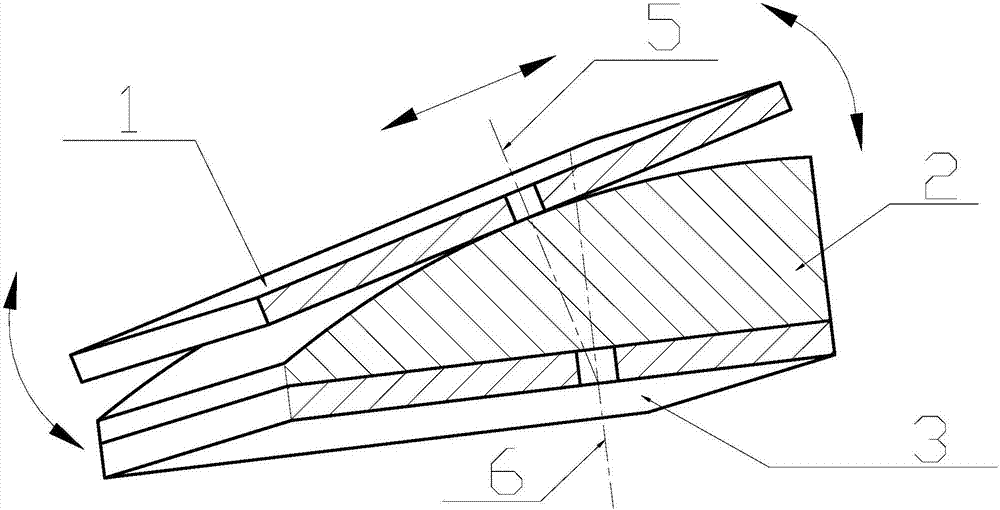

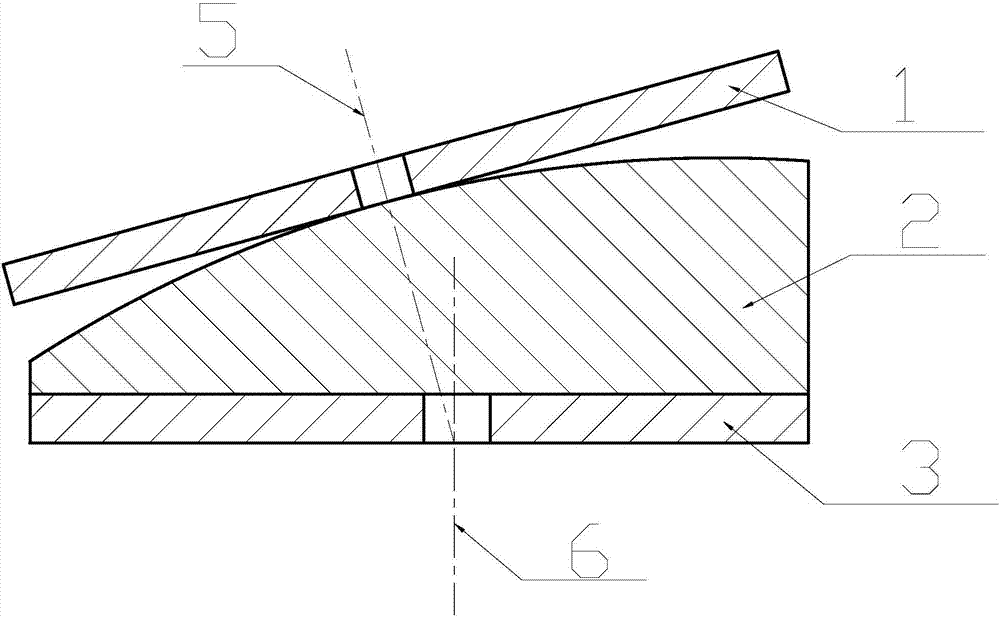

[0018] Fig. 1(a) and Fig. 1(b) are the front view and front view of the traditional model drill bushing. In the figure 1 is the traditional model made on the curved surface, 2 is the part with one side of the curved surface, and 3 is the traditional no-angle Drill sleeve, 5 is the theoretical vector line of the part drilling, 6 is the vector line of the actual process hole.

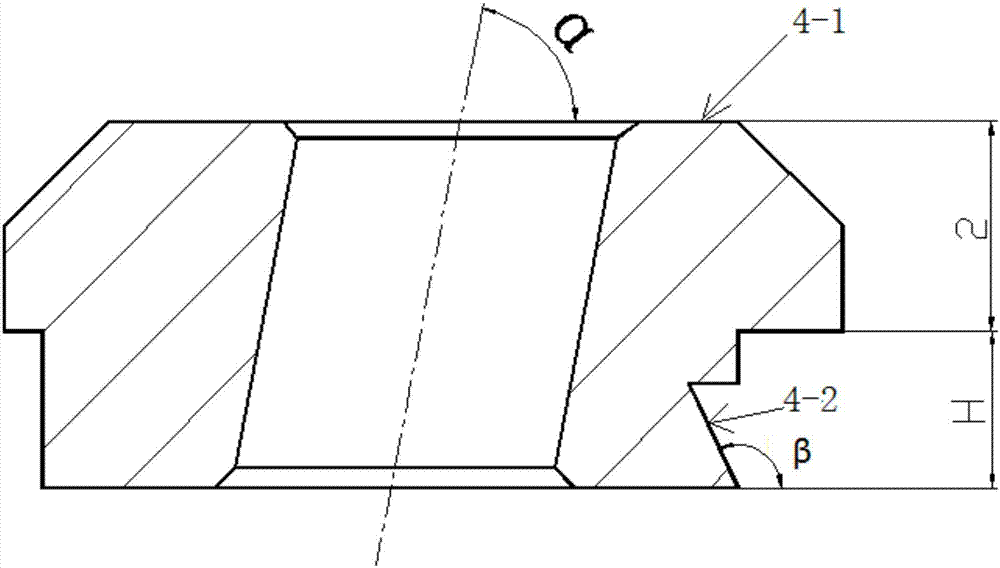

[0019] A guide type embedded drill sleeve, the main body of the drill sleeve is cylindrical, with a sleeve cap 4-1 with a thickness of 2mm, and a groove on the cylindrical surface that is in contact with the traditional sample plate 1 made on the curved surface 4-2, the cross section of the groove 4-2 is triangular, the wedge angle formed by the outer surface of the groove 4-2 and the vertical surface is 75°, and the drill sleeve and the template 2 are interference fit.

[0020] Under MBD technical co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com