An eccentric fixture and a method for producing eccentric shafts by using the eccentric fixture

A technology of eccentric shaft and eccentric clamp, which is applied in the direction of eccentric shaft, clamping, clamping device, etc., can solve the problems such as unsatisfactory eccentricity, and achieve the effect of simple structure, small eccentricity error of parts, and convenient production and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

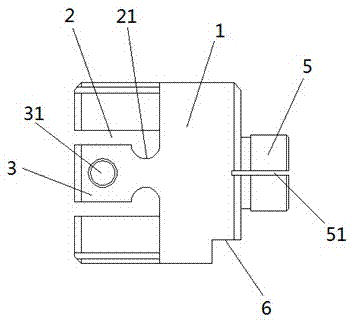

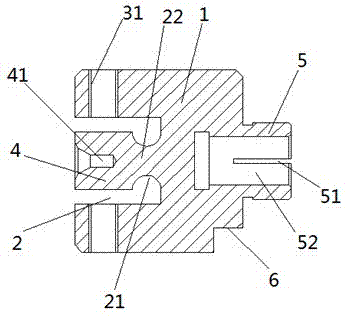

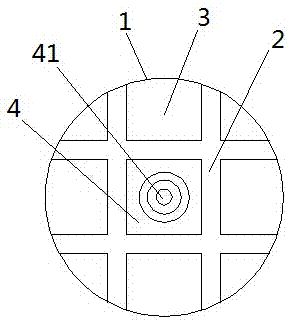

[0024] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, the embodiment of the present invention provides an eccentric clamp, which is used to clamp both ends of the eccentric shaft 32, and the eccentric shaft 32 is installed between the headstock and the tailstock of the machine tool. The eccentric clamp includes a clamp body 1, Clamping ring 7, preferably, the clamping body 1 is in the shape of a cylinder, and its left end face is provided with a top hole 41 along the central axis, and the left end face of the clamping body 1 is divided into two parts by a "well"-shaped groove 2 on the left end face of the clamping body 1. A central block 4 and four eccentricity-adjusting top blocks 3, the central block 4 is located in the middle of the left end face of the clamp body 1, the eccentricity-adjusting top block 3 is distributed around the center block 4, the top hole 41 is located at the center of the center block 4, and the center of the hole The axi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com