Internet-of-things-based intelligent management system for kitchen waste vehicle

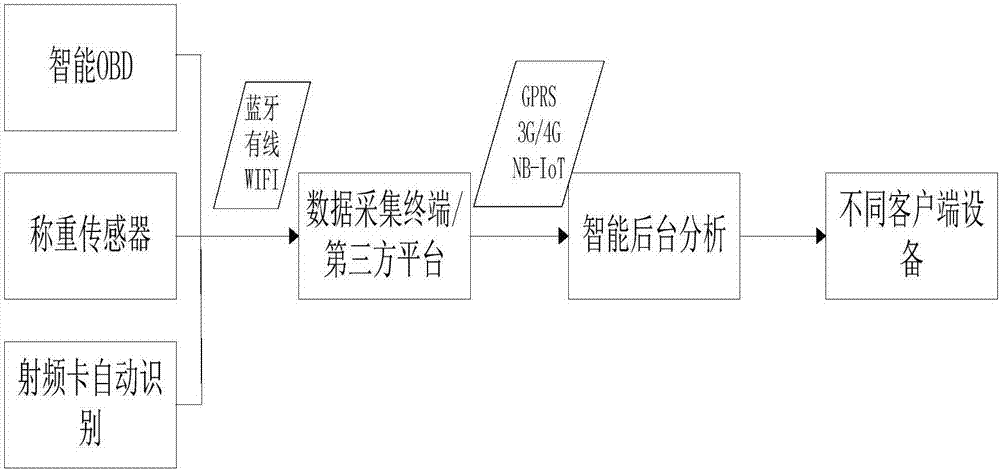

An intelligent management system and technology for garbage trucks, applied in the field of intelligent management systems based on Internet of Things kitchen garbage trucks, can solve the difficulty of vehicle equipment supervision, the authenticity, accuracy, and timeliness of sanitation field operation data, and equipment maintenance costs. Increase and other problems, to achieve the effect of reducing sanitation operating costs, improving the quality of sanitation operations, and moving smoothly and consistently

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

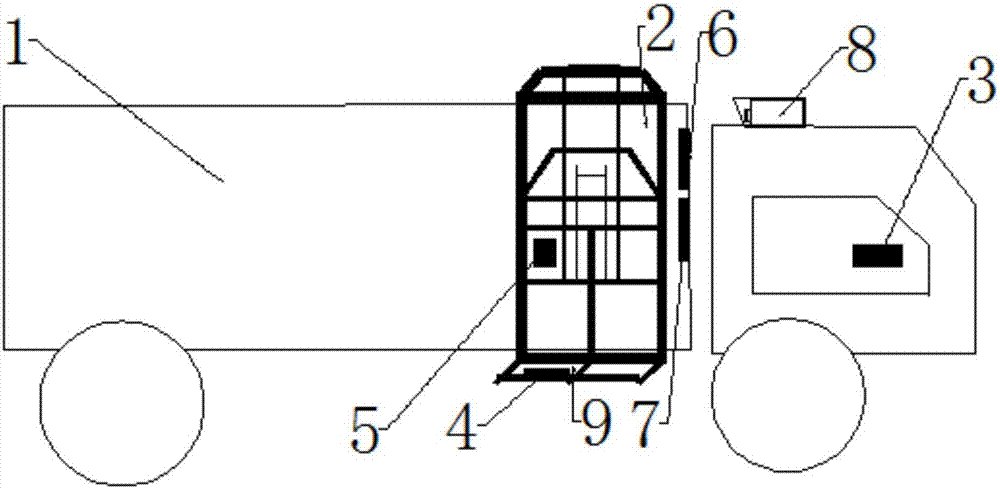

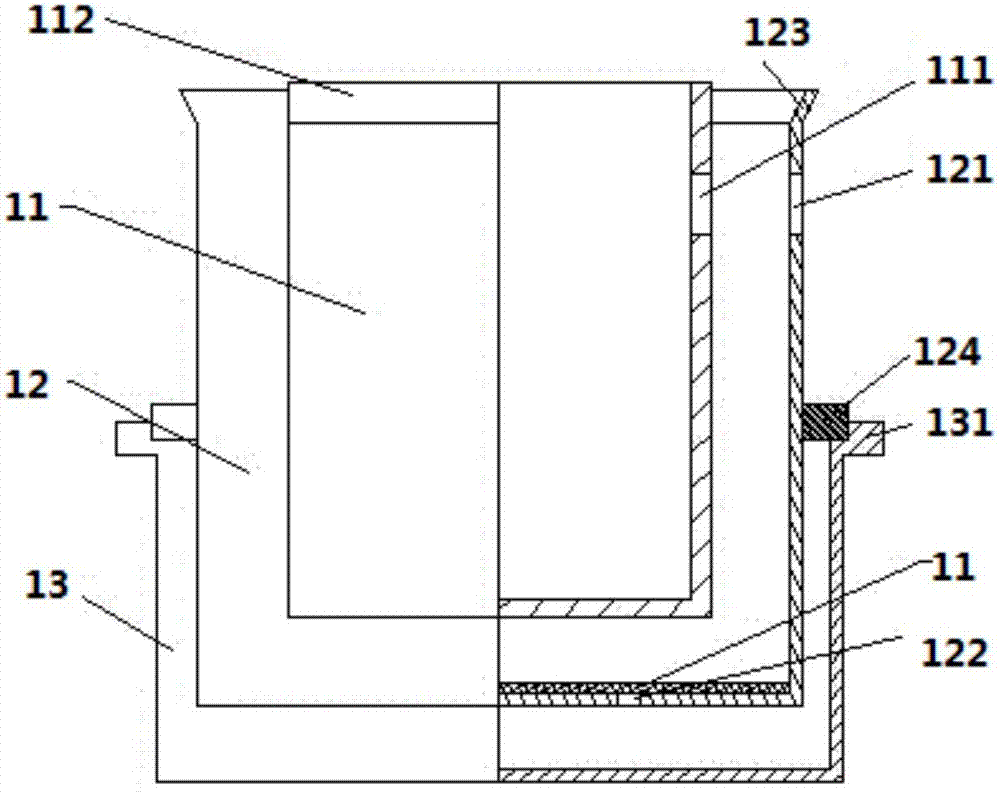

[0059] Taking a restaurant as an example, the garbage can number 0031 is obtained through identification, which is a garbage can in xx street. The garbage can weighs 12kg and has a volume of 120L. The restaurant it belongs to is xx restaurant at 19:30 on September 1, 2016. The weighing sensor 4 weighs 138kg, the photoelectric sensor 6 measures the volume of the garbage volume as 100L, the odor gas detector 7 measures the odor concentration of the kitchen waste as <10, the camera 8 shows it as normal kitchen waste, and the vehicle-mounted OBD The box records the basic information of the garbage truck. The sensor network transmits the real-time data transmission to the fixed data collection terminal on the vehicle through Bluetooth, and the data collection terminal transmits the data to the intelligent background for analysis through GPRS. Through the data in the background, it can be analyzed that the restaurant has 3 garbage cans, and the amount of garbage in one day is 250kg,...

Embodiment 2

[0061] This embodiment provides a trial example of a dump truck in a certain area of Wuhan.

[0062] The operating mode of dump garbage truck, garbage bin and information control system is the same as that of Example 1.

[0063]When the garbage can is hung on the automatic lifting and loading device 2, the identifier of the radio frequency card 10 recognizes the radio frequency card 10, and the number of the garbage can is 0003 through identification, which is a garbage can of the xx business unit. For xx business unit, time 2016.09.02 17:25, at the same time, the weighing sensor 4 on the baffle weighed 265kg, the photoelectric sensor 6 measured the volume of the garbage volume was 220L, and the odor gas detector 7 measured the kitchen waste The odor concentration is <10, the camera 8 displays normal kitchen waste, and the vehicle-mounted OBD box records the basic information of the garbage truck. The sensor network transmits the real-time data transmission to the fixed dat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com