Hoist segment crane for large shield machine

A shield machine and winch-type technology, which is applied in the direction of cranes, load-hanging components, trolley cranes, etc., can solve the problem that the lifting capacity cannot meet the segment lifting work of large-diameter shield machines, and it is not suitable for fast lifting Problems such as large-diameter segments, unable to meet the rapid construction progress, etc., achieve the effect of high structural protection level, large lifting capacity, and reduced headroom size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

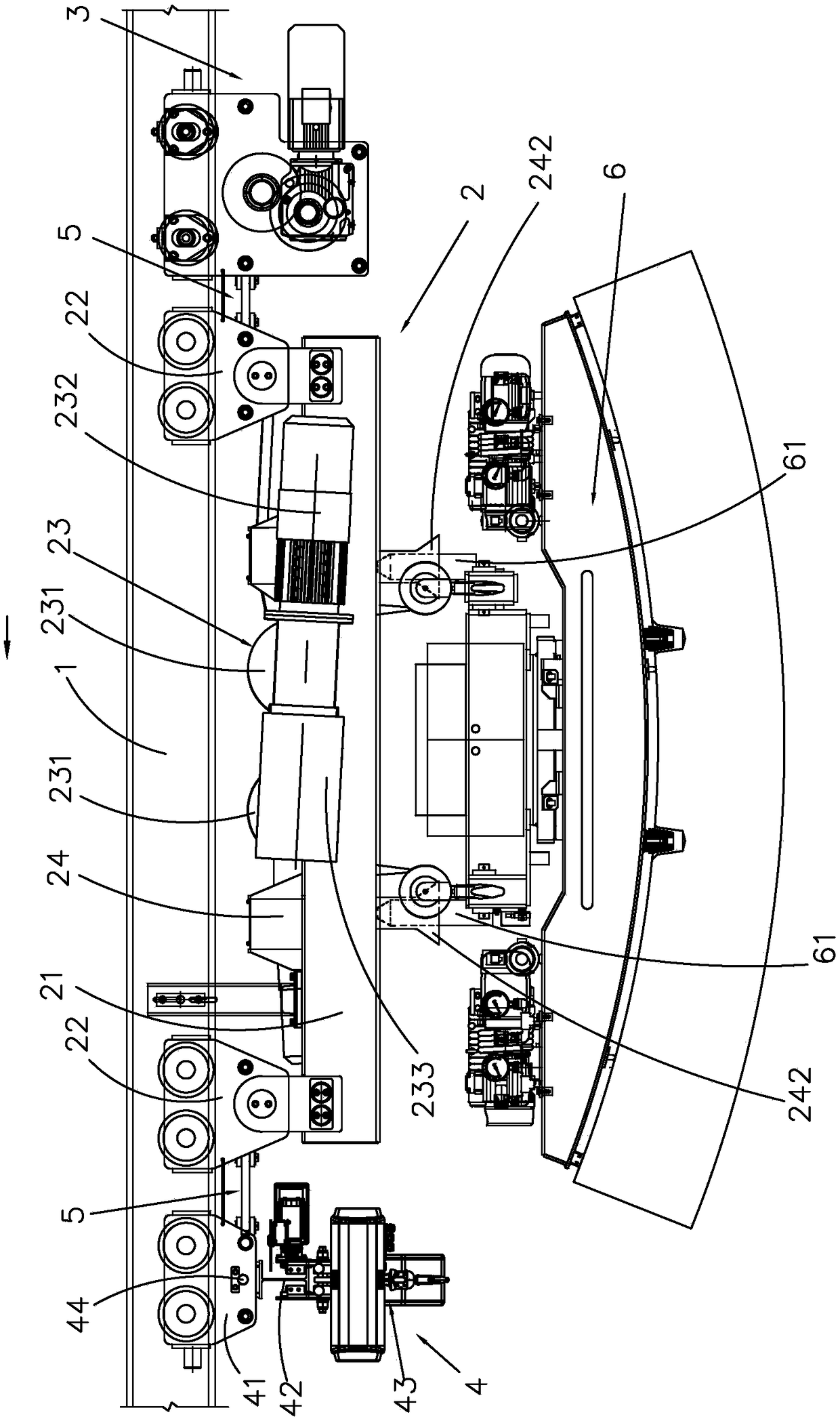

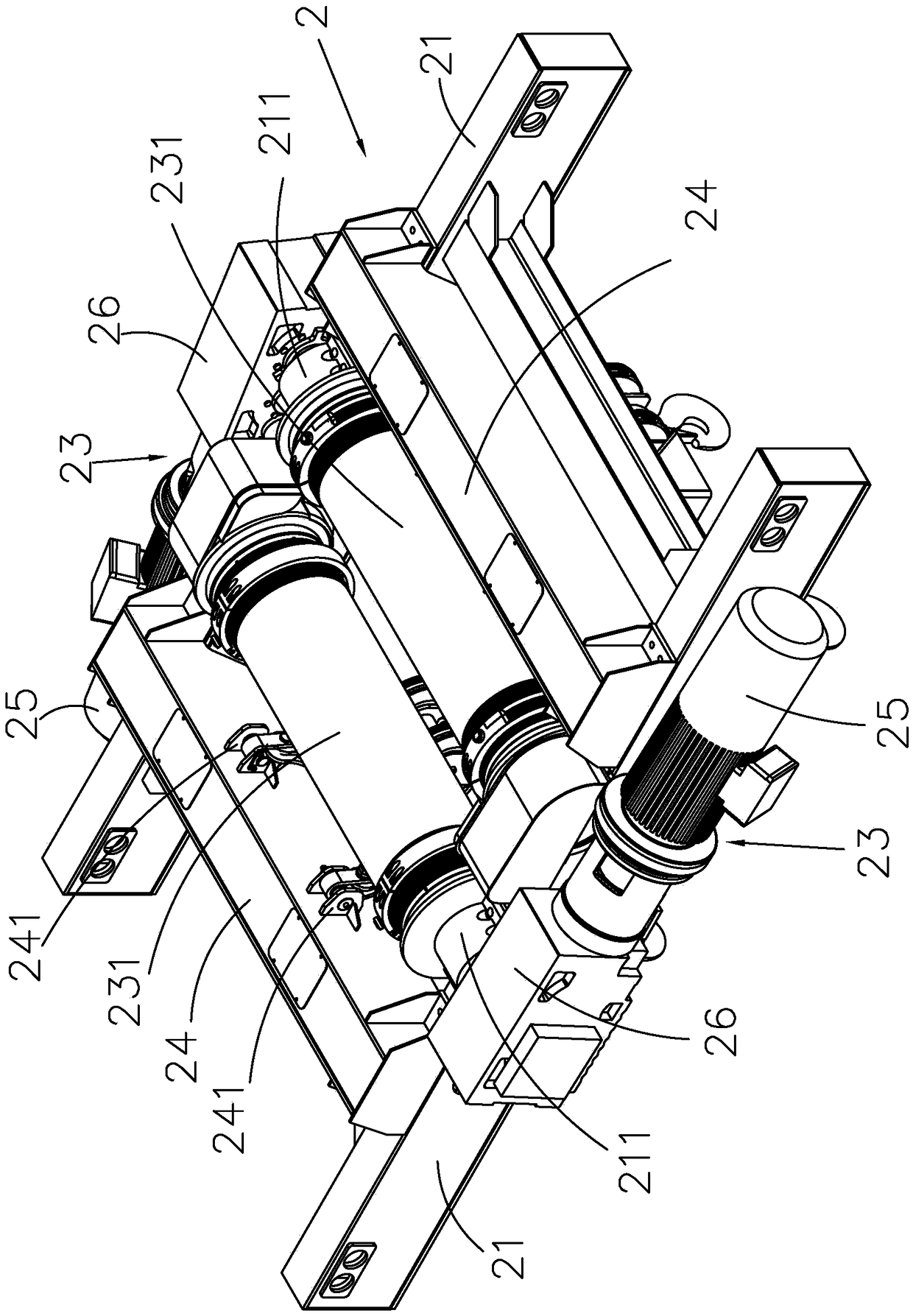

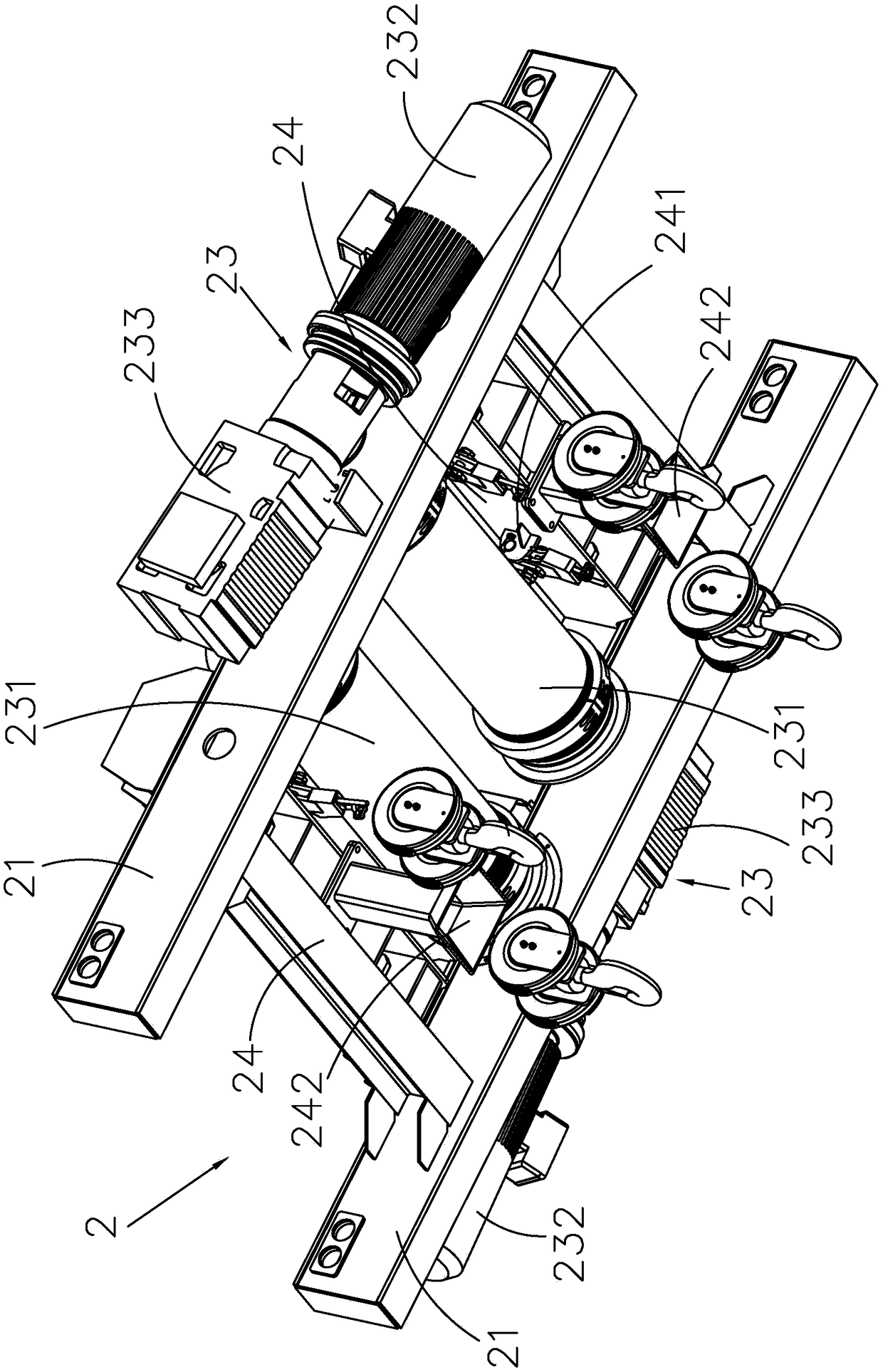

[0025] Referring to the attached drawings, a winch-type segment crane suitable for large-scale shield machines includes a segment hoisting device 2 including a first driven trolley 22 arranged between two parallel running tracks 1 . A power trolley 3 for driving the segment lifting device 2 to move along the running track 1 . The segment hoisting device 2 is used as the hoisting mechanism 23 of the segment crane, and the power trolley 3 is used as the driving part of the segment crane.

[0026] Power trolley 3 is conventional technology: as attached figure 1 As shown: it is mainly composed of driving three-in-one motor, gear transmission, driving sprocket, wall panels arranged on both sides of the running track 1, adjustable wheel sets, etc. The adjustable wheel is to adjust the adjustment nut on the wheel set to adjust the gap between the sprocket and the roller chain, so that the trolley runs smoothly.

[0027] as attached Figure 1-4 As shown, the segment lifting device ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com