A method for reducing the minimum eutectic point of low-heat Portland cement clinker

A technology of Portland cement and eutectic point, which is applied in the field of building materials, can solve the problems of unfavorable construction progress and project quality of concrete projects, hinder the large-scale application of hydraulic dams, and low early strength of low-heat Portland cement, etc., to achieve the lowest reduction Eutectic point, make up for the lack of early strength, and improve the effect of early strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

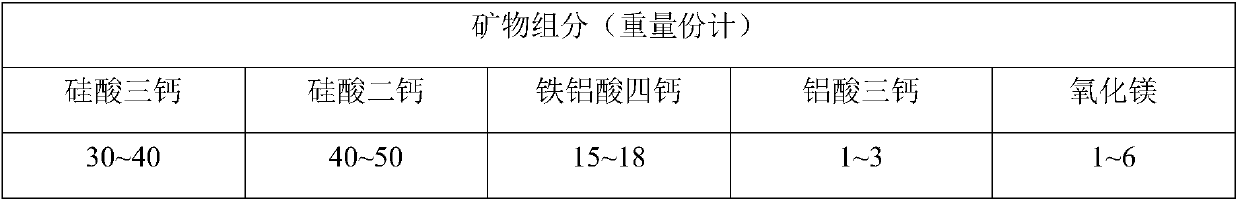

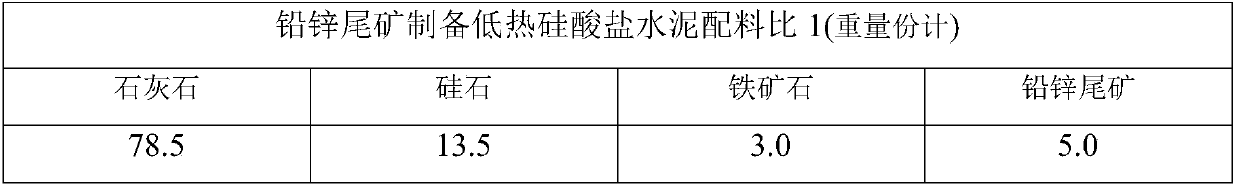

[0028] Limestone, silica, lead-zinc tailings, and iron ore are used as raw materials (see Table 1 for chemical composition). According to the mineral composition of the low-heat Portland cement clinker designed in Table 2, the lime saturation coefficient of the low-heat Portland cement clinker is 0.78; the silicon rate is 2.6; the aluminum rate is 0.68, the chemical composition of the clinker is calculated, and the batching is carried out. The results are in parts by weight, and the ratio of raw materials is shown in Table 3. These raw materials are put together into a ball mill and ground to 80 μm square hole sieve with ≤12% of the raw meal powder, and the raw meal powder is burned to melt and cooled to obtain low-heat portland cement clinker. The raw meal powder is placed in a video-type sintering point tester to raise the temperature, and the heating rate is controlled at 50°C / min when the temperature is below 850°C; it is controlled at 5°C / min when it is above 850°C. The ...

Embodiment 2

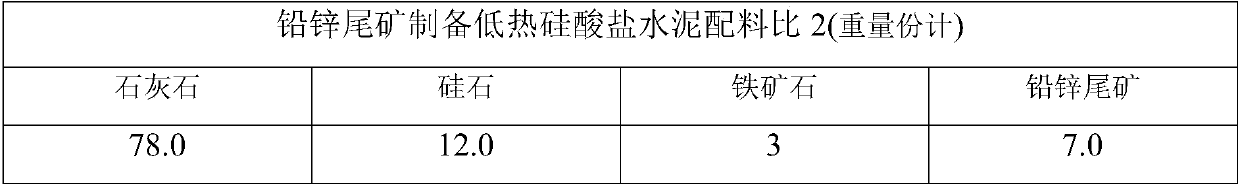

[0039] Limestone, silica, lead-zinc tailings, and iron ore are used as raw materials (see Table 1 for chemical composition). According to the mineral components of the low-heat Portland cement clinker designed in Table 2, the lime saturation coefficient of the low-heat Portland cement clinker is 0.82; the silicon rate is 2.8; the aluminum rate is 0.72, the chemical composition of the clinker is calculated, and the batching is performed. The results are in parts by weight, and the ratio of raw materials is shown in Table 5. Put these raw materials together and grind them until the raw meal powder with a residue of ≤11% is sieved through an 80 μm square hole sieve. The raw meal powder is placed in a video-type sintering point tester to raise the temperature, and the heating rate is controlled at 50°C / min when the temperature is below 850°C; it is controlled at 5°C / min when it is above 850°C. The lowest eutectic point was determined by a video sintering point tester.

[0040] L...

Embodiment 3

[0046] Limestone, silica, lead-zinc tailings, and iron ore are used as raw materials (see Table 1 for chemical composition). According to the mineral components of the low-heat Portland cement clinker designed in Table 2, the lime saturation coefficient of the low-heat Portland cement clinker is 0.79; the silicon rate is 2.7; the aluminum rate is 0.69, the chemical composition of the clinker is calculated, and the batching is performed. The results are in parts by weight, and the ratio of raw materials is shown in Table 7. Put these raw materials together into an experimental ball mill and grind until ≤10% raw meal powder is sieved through an 80 μm square hole sieve. The raw meal powder is placed in a video-type sintering point tester to raise the temperature, and the heating rate is controlled at 50°C / min when the temperature is below 850°C; it is controlled at 5°C / min when the temperature is above 850°C. The lowest eutectic point was determined by a video sintering point te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com