Tailing efficient recovery treatment method

A technology for recycling and tailings, which is applied in grain processing, process efficiency improvement, lighting and heating equipment, etc., can solve the problems of insufficient original innovation, high energy consumption, secondary pollution, and difficulty in wide-scale promotion, and achieve reduction Effects of cost and energy consumption, reduction of land occupation, and product quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

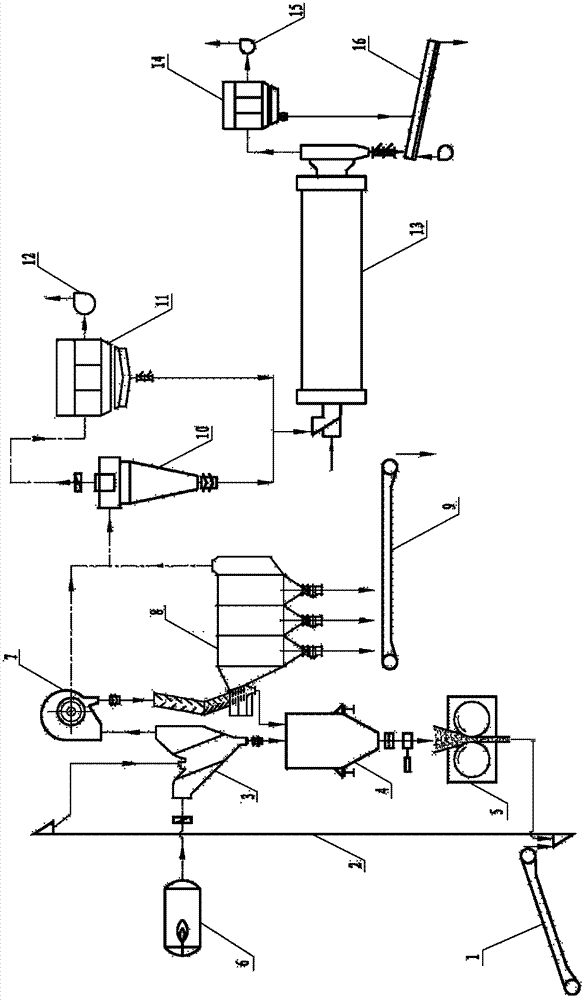

[0027] A method for efficiently recycling tailings, the steps of which are:

[0028] A. The tailings containing moisture are dried online by the hot blast furnace heating and drying system:

[0029] The hot blast stove heating and drying system includes ZDFR25 gas-fired hot blast stove 6, TS9620G dryer 3, and TS3400 classifying powder separator 7.

[0030] The tailings raw materials from the tailings yard are sent to the tailings grinding workshop through the B800 belt conveyor (1), and sent to the TS9620G dryer 3 by the TS1200-52 bucket elevator 2, and the materials are dispersed on the distribution plate. The tailings entering the factory contain a lot of moisture, and the ZDFR25 gas-fired hot air stove 6 is used for heating, and the heat exchange is performed in the TS9620G dryer 3 to dry the tailings. The dried tailings enter the φ3m weighing and steady flow through the slide Bin 4.

[0031] The hot air drying system provides adjustable hot air temperature of 350-450°C, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| thermal efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com