A kind of preparation method of healable ion gel polymer electrolyte

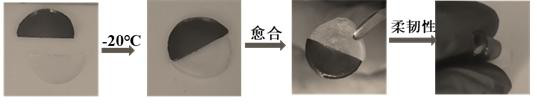

An ion gel, polymer technology, used in non-aqueous electrolyte batteries, sustainable manufacturing/processing, circuits, etc., can solve problems such as long healing time, achieve broad application prospects, large electrochemical window, and excellent autonomous self-healing effect of ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Accurately weigh 0.0718 g lithium bistrifluoromethanesulfonimide (LiTFSI) (0.25 mmol) and 2.5 g 1-ethyl-3-methylimidazole bistrifluoromethanesulfonimide salt (BMImTFSI) (6.4 mmol) Add to the beaker, and add small magnetic particles to the beaker and stir to dissolve at room temperature to obtain ionic liquid solution B doped with 0.1mol / kg LiTFSI

Embodiment 2

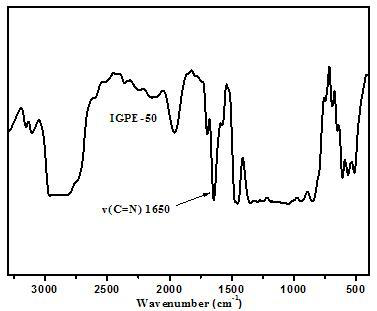

[0030] Weigh 0.0067g of 1,3,5-triformylbenzene (TPB), 0.125g of diaminopolyethylene glycol (PEG-diamine), 0.0328g of doped 0.1mol / kg LiTFSI of ionic liquid solution B, and simultaneously pipette 500 μl of anhydrous acetonitrile solvent to make [amine] 0 = [aldehyde] 0 = 0.25M. Then the mixture was stirred on an intelligent constant temperature timed magnetic stirrer for 1 h to dissolve completely. Once the solution has become homogeneous, use a pipette to slowly transfer it to a Teflon mold to minimize the formation of air bubbles, the top and bottom of the mold are covered with two microscope slides, allowing the mixture to cool at room temperature. Let stand in the mold for 1 hour. The ion gel polymer electrolyte membrane (IGPE-20) was obtained, which was finally put into a vacuum drying oven and dried at 80°C.

Embodiment 3

[0032] Weigh 0.0067g of 1,3,5-triformylbenzene (TPB), 0.125g of diaminopolyethylene glycol (PEG-diamine), 0.0709g of doped 0.1mol / kg LiTFSI of ionic liquid solution B, and simultaneously pipette 500 μl of anhydrous acetonitrile solvent to make [amine] 0 = [aldehyde] 0 = 0.25M. Then the mixture was stirred on an intelligent constant temperature timed magnetic stirrer for 1 h to dissolve completely. Once the solution has become homogeneous, use a pipette to slowly transfer it to a Teflon mold to minimize the formation of air bubbles, the top and bottom of the mold are covered with two microscope slides, allowing the mixture to cool at room temperature. Let stand in the mold for 1.5 hours. The ion gel polymer electrolyte membrane (IGPE-35) was obtained, and finally it was put into a vacuum drying oven and dried at 80°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com