A kind of method for continuously preparing bisoxalate lithium borate

A technology of lithium bis-oxalate borate and oxalate is applied in the field of continuous preparation of lithium bis-oxalate borate, which can solve the problems of high resistance of SEI film, battery capacity attenuation, limitation of working conditions, etc., and achieves good electrochemical stability and thermal stability, The effect of improving electrical conductivity and high thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

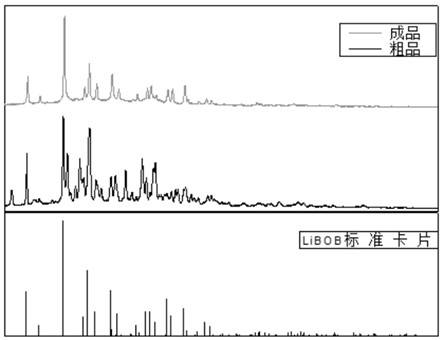

Image

Examples

Embodiment 1

[0024] The present invention provides the following technical solutions: a method for continuously preparing lithium bisoxalate borate, comprising the following steps:

[0025] Step (1): Weigh lithium hydroxide, boric acid and oxalic acid according to Li:B:C2O4 with a molar ratio of 1:1:2.05, and grind them with a ball mill for 45 minutes respectively.

[0026] Step (2): Slowly add the three materials in proportion to the stirring tank at room temperature, and slowly add a small amount of pure water, the amount of water accounts for about 3% of the weight of the solid material, and adjust the material to mix evenly.

[0027] Step (3): Turn on the feeder, add the mixed material obtained in step (2) into the feeding bin of the three-stage temperature zone rotary reaction furnace, and send the material into the reaction furnace at a rate of 0.5kg per hour for reaction. Turn on the nitrogen gas, and keep the pressure inside the furnace tube slightly positive.

[0028] Step (4): T...

Embodiment 2

[0033] The present invention provides the following technical solutions:.

[0034] Step (1): Lithium hydroxide, boric acid and oxalic acid were weighed at a molar ratio of 1:1:2.10 according to Li:B:C2O4, and were milled for 30 minutes by a ball mill.

[0035] Step (2): Slowly add the three materials in proportion to the stirring tank at room temperature, and slowly add a small amount of pure water, the amount of water accounts for about 4% of the weight of the solid material, and mix the materials evenly.

[0036] Step (3): Turn on the feeder, add the mixed material obtained in step (2) into the feeding bin of the three-stage temperature zone rotary reaction furnace, and send the material into the reaction furnace at a rate of 0.7kg per hour for reaction. Turn on the nitrogen gas, and keep the pressure inside the furnace tube slightly positive.

[0037] Step (4): The material passes through the first reaction temperature zone, the temperature is 90°C, the residence time of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com