A low-temperature method for preparing high-performance ZnO-based transparent conductive oxide films

An oxide thin film, transparent and conductive technology, applied in liquid chemical plating, metal material coating process, coating, etc., can solve the problems of poor photoelectric performance of thin film samples, achieve excellent photoelectric performance, easy composition, and reduce crystal lattice Can effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

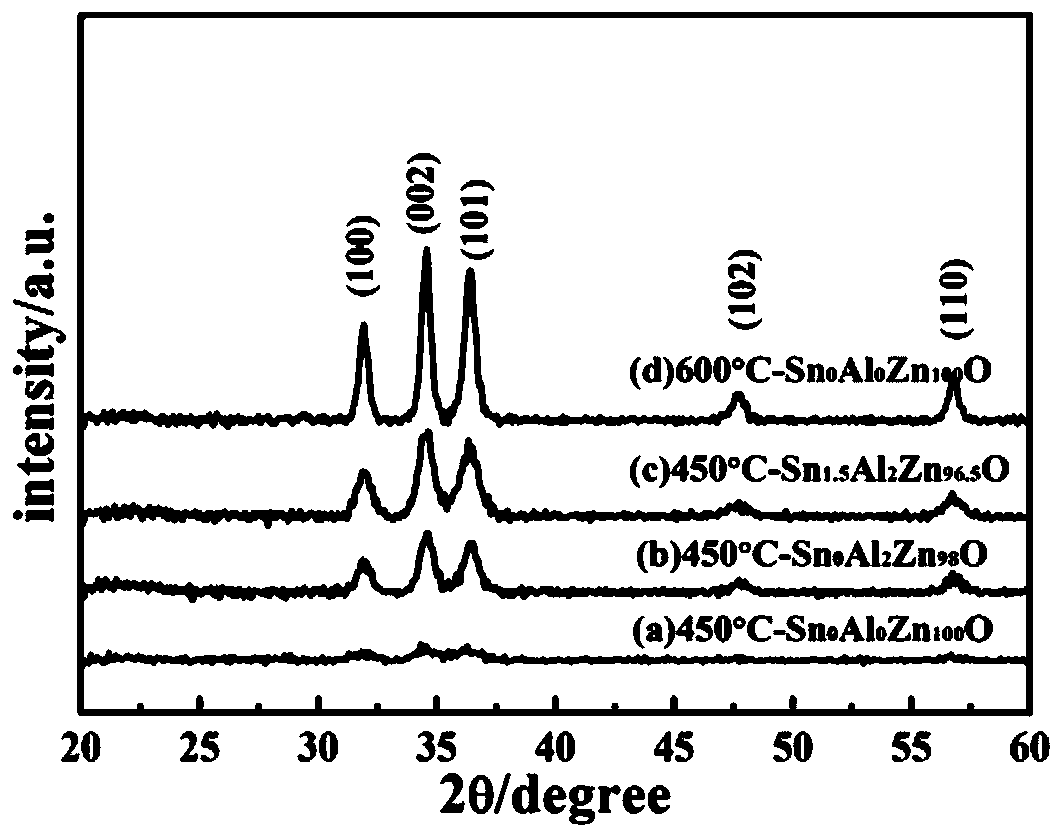

Image

Examples

Embodiment 1

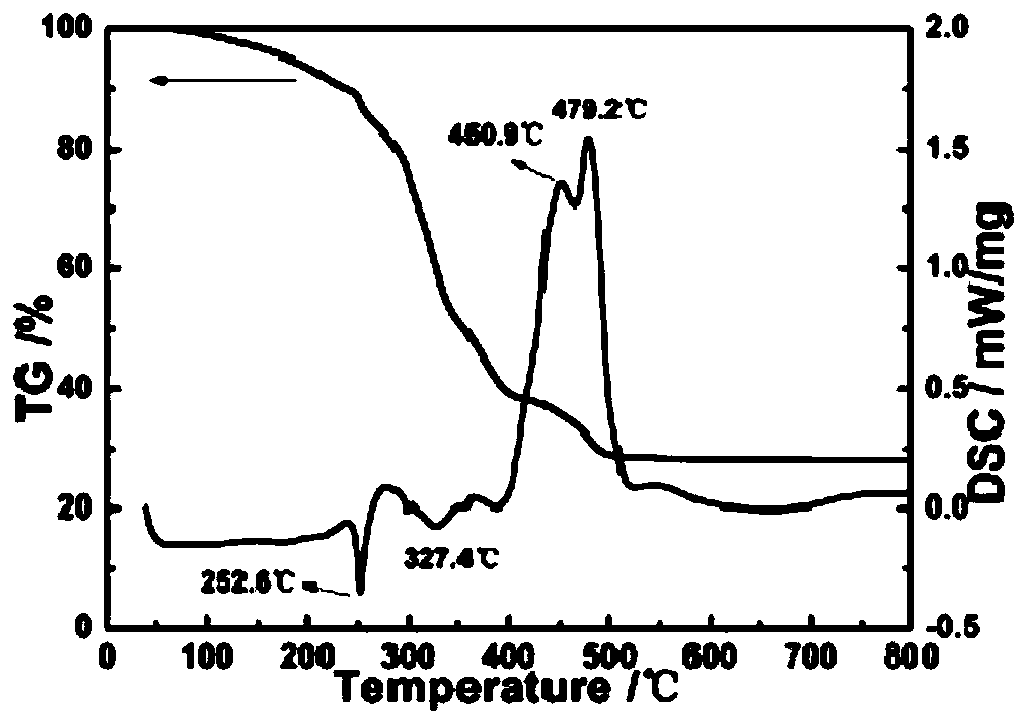

[0043] A method for preparing a low-temperature high-performance transparent conductive oxide film, comprising the following steps:

[0044] (1) According to the chemical composition Al 0.02 Zn 0.98 The stoichiometric ratio of O element weighs 3.2594g zinc acetate dihydrate (Zn(CH 3 COO) 2 2H 2 O) and 0.1137g aluminum nitrate nonahydrate (Al(NO 3 ) 3 9H 2 (2), after being dissolved in 20mL of solvent ethylene glycol methyl ether, 0.9mL of ethanolamine with an equimolar ratio of metal ions is added dropwise in the solution with a dropper, and then constant volume makes the sol concentration be 0.3M / L , heated the prepared solution to 60°C and stirred for 3 hours, then filtered, and the obtained clear solution was allowed to stand at room temperature for 48 hours to allow it to fully age to form a clear and transparent sol for use;

[0045] (2) After the quartz substrate was ultrasonically cleaned in acetone, ethanol and deionized water for 20 minutes, a clean substrate w...

Embodiment 2

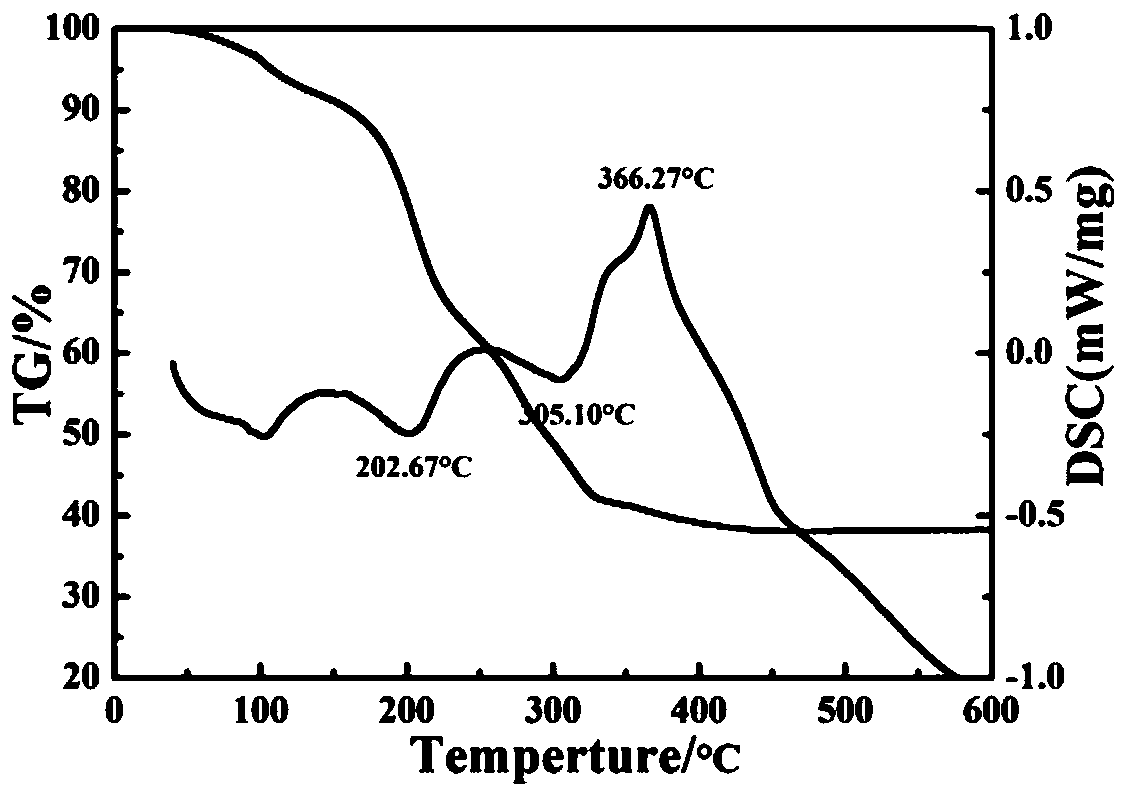

[0050] A method for preparing a low-temperature high-performance transparent conductive oxide film, comprising the following steps:

[0051] (1) According to chemical composition, Al 0.01 Zn 0.99 O(1#), Al 0.03 Zn 0.97 O(2#) and Al 0.04 Zn 0.96 The stoichiometric ratio of the O(3#) element weighs zinc acetate dihydrate (Zn(CH 3 COO) 2 2H 2 O) and aluminum nitrate nonahydrate (Al(NO 3 ) 3 9H 2 (2), the specific dosage is as shown in Table 1. After it is dissolved in 20mL of solvent ethylene glycol methyl ether, 0.9mL ethanolamine with an equimolar ratio to the metal ion is added dropwise in the solution with a dropper, and then the volume is made to make the sol The concentration is 0.3M / L, the prepared solution is heated to 60°C and stirred for 3 hours, then filtered, and the obtained clear solution is allowed to stand at room temperature for 48 hours to allow it to fully age to form a clear and transparent sol for use;

[0052] Table 1

[0053]

[0054] (2) Aft...

Embodiment 3

[0059] A method for preparing a low-temperature high-performance transparent conductive oxide film, comprising the following steps:

[0060] (1) According to the chemical composition Sn 0.015 Al 0.02 Zn 0.965 The stoichiometric ratio of O element weighs 3.2095g zinc acetate dihydrate (Zn(CH 3 COO) 2 2H 2 O), 0.1137g aluminum nitrate nonahydrate (Al(NO 3 ) 3 9H 2 O) 0.1137g and 0.0797g tin tetrachloride pentahydrate (SnCl 4 ·5H 2 (0), after it is dissolved in the solvent ethylene glycol methyl ether of 20mL, the ethanolamine (0.9mL) of equimolar ratio with metal ion is added dropwise in the solution with dropper, then constant volume makes sol concentration be 0.3M / L, heated the prepared solution to 60°C and stirred for 3 hours, then filtered, and the obtained clear solution was allowed to stand at room temperature for 48 hours to allow it to fully age to form a clear and transparent sol for use;

[0061] (2) After the quartz substrate was ultrasonically cleaned in a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com