Flood season railway culvert roof sheathing method

A technology for culverts and railways, which is applied in the field of railway culvert roofing during the flood season. It can solve the problems of affecting the service life of culverts, affecting the stability of railway equipment, and occupying a large site, so as to meet the requirements of construction progress, reduce construction interference, and facilitate operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

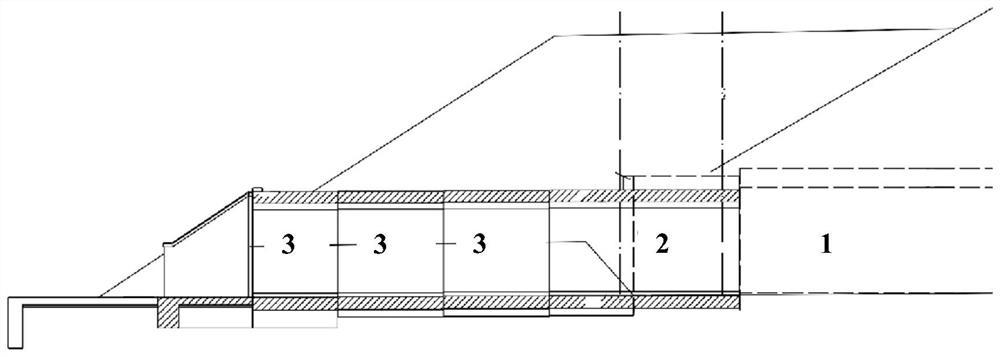

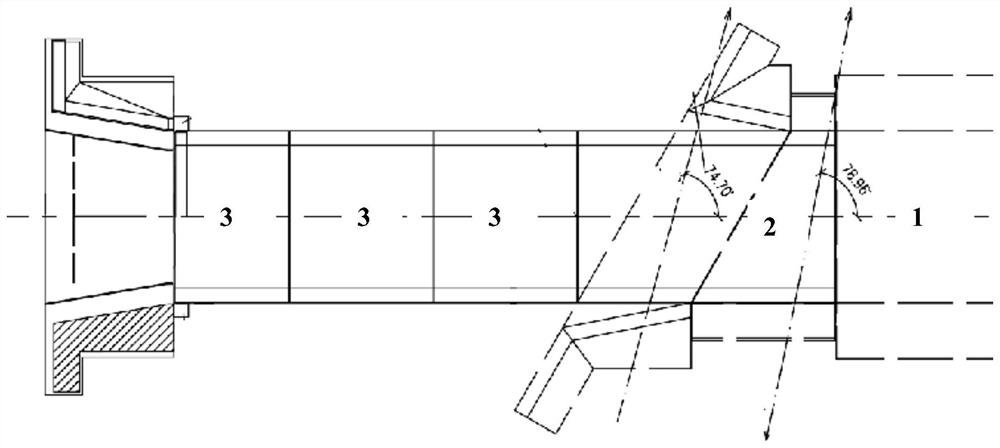

[0022] The existing slab culvert in a special railway line project is a drainage culvert, and the culvert that needs to be newly extended is a 1-5m frame culvert with a length of 23.06m, which is divided into 4 culvert sections, of which the culvert close to the existing slab culvert The length of the first culvert section is 9.0m, and the jacking method is adopted for construction, and the jacking distance is 10.3m. The remaining 3 culvert sections are constructed by in-situ cast-in-place method. The net height of the culvert is 4.45m, the excavation depth of the foundation pit is 2.27m, the thickness of the culvert wall is 0.5m, the thickness of the culvert floor is 0.6m, and the thickness of the roof is 0.55m. The risk is high, and it is a heavy and difficult controlled project. The applicant successfully completed the project by adopting the method for roofing railway culverts in the flood season provided by the present invention.

[0023] The present invention will be des...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com