Operation method of internal combustion engine and internal combustion engine

An operation method and internal combustion engine technology, applied to internal combustion piston engines, combustion engines, machines/engines, etc., to achieve the effects of increasing opening, increasing mass flow, and reducing ventilation loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

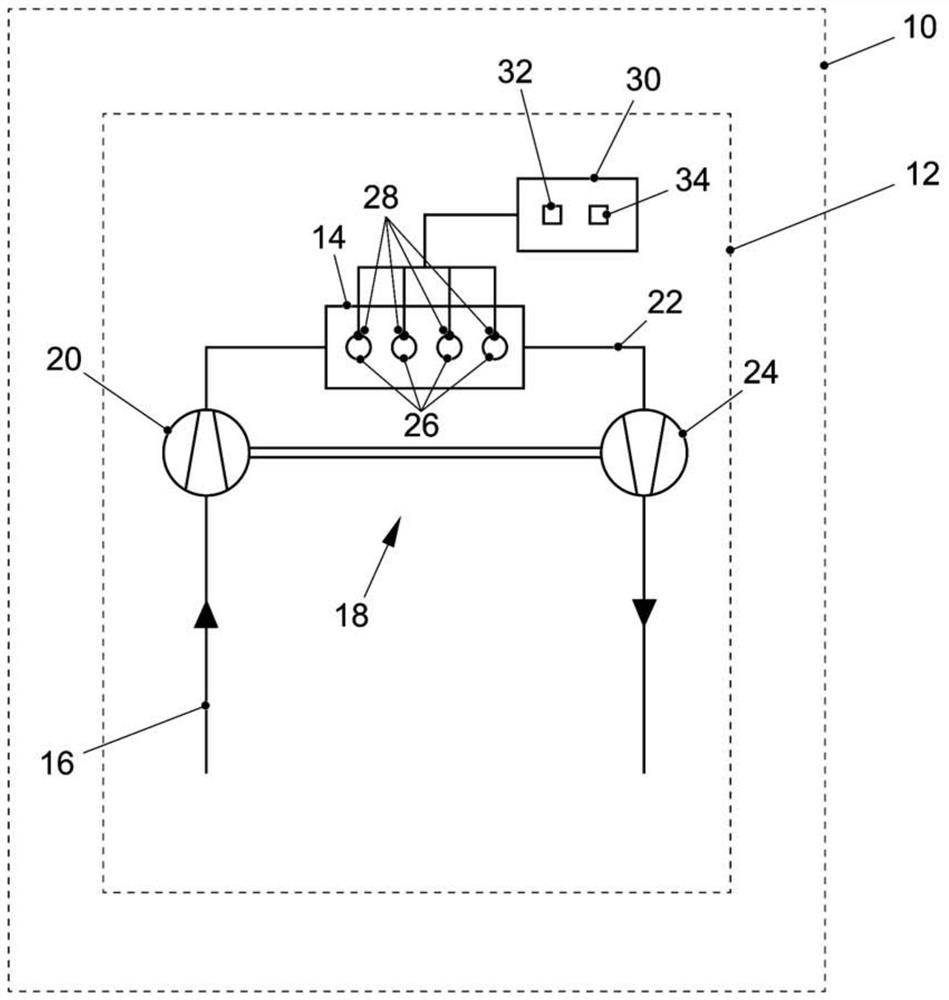

[0029] figure 1 A topological diagram of an embodiment of an internal combustion engine 12 in a motor vehicle 10 , which is operated with gas, in particular natural gas or CNG, is shown, including an engine control unit 30 and an engine block 14 . In this preferred embodiment, the internal combustion engine 12 is an externally ignited internal combustion engine.

[0030] Internal combustion engine 12 can be supercharged by means of an exhaust gas turbocharger 18 . Air is supplied to an engine block 14 , preferably here as an example a piston engine with four combustion chambers 26 , via a fresh air arrangement 16 . Air is compressed into the fresh gas system 16 via a compressor 20 of the exhaust gas turbocharger 18 . A throttle, not shown here, is located downstream of the compressor 20 . Each combustion chamber 26 is assigned a gas injector 28 with which gas can be introduced directly into the combustion chamber. The gas is distributed to the gas injectors 28 from a gas t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com