Circular steam conveying energy-saving system

An energy-saving system and steam technology, which is applied in pipeline systems, thermal insulation, pipes/pipe joints/pipe fittings, etc., can solve the problems of high heat insulation cost of transportation pipelines, reduce steam transportation efficiency, and high steam humidity, and improve heat exchange efficiency. Effect of heat exchange, reduction of heat loss, effect of temperature increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

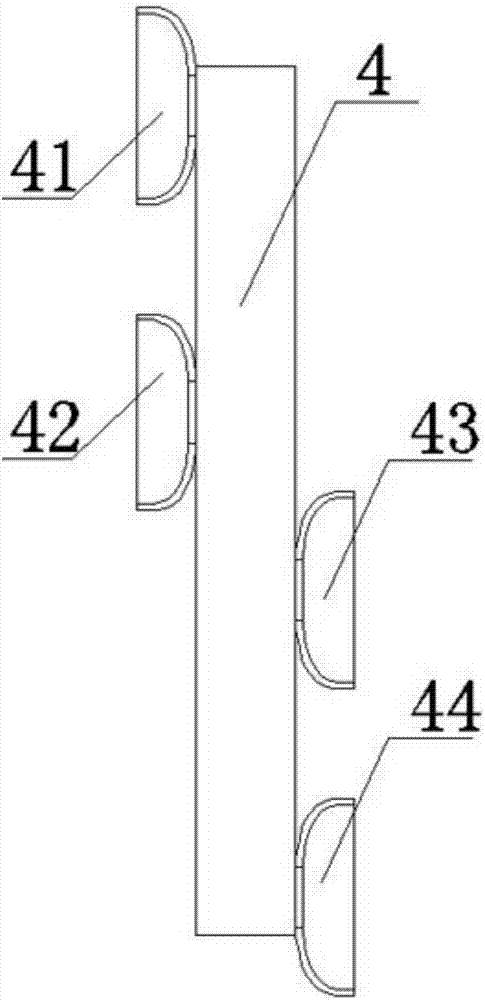

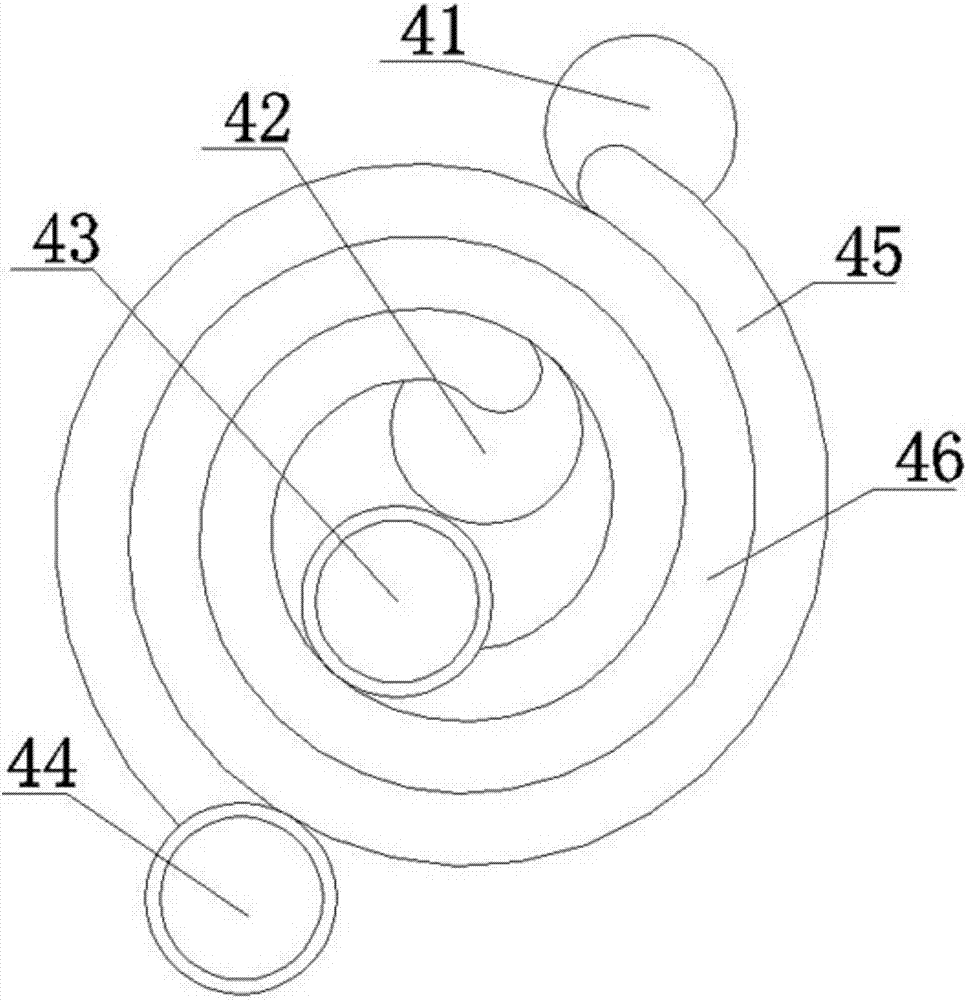

[0039] An energy-saving system for cyclic steam delivery, which includes a number of steam delivery pipes, which are connected through connecting plates 4 to form delivery channels for delivering steam. A connection connecting plate 4 is set between every two adjacent steam conveying pipes. Connecting plate 4—…——steam conveying pipe—connecting connecting plate 4—steam conveying pipe—connecting connecting plate 4—steam conveying pipe—connecting connecting plate 4—steam conveying pipe—connecting connecting plate 4. The connection adapter 4 includes a steam delivery inlet port 41, a steam delivery outlet interface 43, a heat exchange inlet interface 42 and a heat exchange outlet interface 44, and the steam delivery inlet interface 41 connected to the adapter plate 4 communicates with the steam delivery pipe in the front section. The steam transported in the steam delivery pipe of the previous section enters the connection adapter 4 through the steam delivery inlet port 41; the st...

Embodiment 2

[0041] On the basis of Embodiment 1, in order to improve the heat exchange efficiency of the heat exchange medium for the steam in the steam delivery pipeline and increase the temperature of the steam in the steam delivery pipeline, the heat exchange medium is heat transfer oil.

Embodiment 3

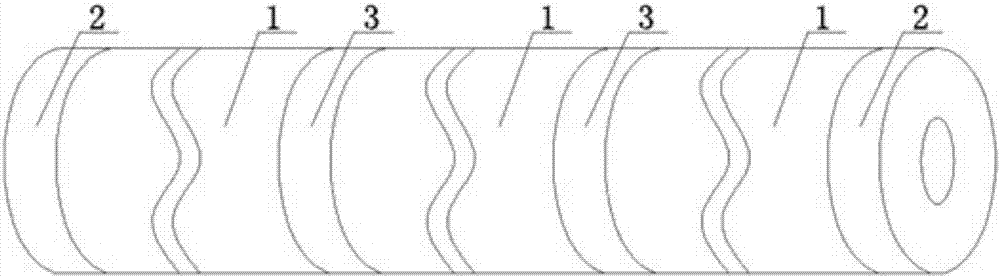

[0043] On the basis of Embodiment 1 or Embodiment 2, in order to improve the assembly efficiency of the steam delivery pipe, the steam delivery pipe is arranged in a spliced structure. The steam conveying pipe includes several conveying pipe units 1 , two adjacent conveying pipe units 1 are connected by an intermediate connector 3 , and the ends of the conveying pipe units 1 at both ends are connected by end connectors 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com