Method for determining corresponding retained austenite content during bearing steel material thermal processing

A technology of retained austenite and heat treatment process, applied in the field of physics, can solve the problems of long analysis and measurement process and high cost, and achieve the effect of high accuracy of experimental data, less consumables and fast speed

Inactive Publication Date: 2017-06-27

SHANGHAI INST OF TECH

View PDF3 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0005] Aiming at the above-mentioned technical problems in the prior art, the present invention provides a method for measuring the corresponding residual austenite content in the heat treatment process of the bearing steel material. The corresponding residual austenite content in the heat treatment process of the bearing steel material is The determination method of content should solve the technical problems of high cost and long analysis and measurement process of measuring retained austenite content by X-ray diffraction method in the prior art

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0028] A method for measuring the corresponding retained austenite content in the heat treatment process of a bearing steel material, the specific operation steps are as follows:

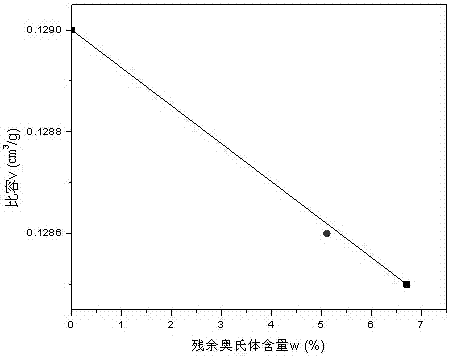

[0029] (1) First establish the working curve of the retained austenite content and specific volume of the bearing steel material to be tested

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

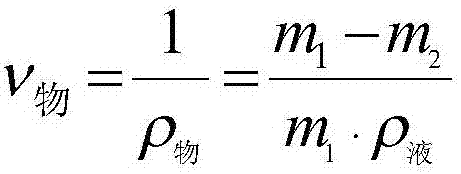

The invention discloses a method for determining corresponding retained austenite content during bearing steel material thermal processing. The method includes: measuring the corresponding specific volume of a to-be-determined bearing steel material under different thermal processing states, performing an X-ray experiment on the bearing steel test sample obtained through electrolytic polishing and sample preparation to obtain the retained austenite content, and using the retained austenite content as the horizontal coordinate and the specific volume of the to-be-determined bearing steel material as the longitudinal coordinate to build a relationship, namely a working curve, between the retained austenite content and the specific volume of the to-be-determined bearing steel material; quantitatively determining the corresponding retained austenite content of the to-be-determined bearing steel material under one thermal processing state according to the obtained working curve and the position of the specific volume of the to-be-determined bearing steel material in the working curve or by comparing the specific volume under different thermal processing states. The method is simple in test sample preparation, universal in measuring instrument, convenient to operate, high in experiment data precision, high in repeatability, reliable in data, and the like.

Description

technical field [0001] The invention belongs to the field of physics, and relates to a method for measuring the content of retained austenite, in particular to a method for measuring the content of retained austenite corresponding to the heat treatment process of bearing steel materials. Background technique [0002] In finished bearing parts, especially precision bearing parts, there are strict requirements on dimensional stability. Retained austenite is an unstable phase in Cr-containing steel such as bearing steel. It will undergo a phase transformation of volume change during the storage or use of finished parts. This transformation will lead to dimensional changes in the bearing and affect the accuracy of the bearing. It can even lead to scrapping. Therefore, accurate measurement and control of retained austenite is a key technology to ensure the dimensional stability of bearing parts and thus the normal use of bearings. [0003] Theoretical calculations show that for...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): G01N23/20G01N9/36

CPCG01N23/20G01N9/36

Inventor 陈锟刘琦刘克家陈惠芬陈麒忠吴新猛

Owner SHANGHAI INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com