Prediction control system and method for polyethylene quality index system

A quality index, predictive control technology, applied in general control systems, adaptive control, control/regulation systems, etc., can solve problems such as adverse effects on system control quality, inability to process sensor signals, and threats to safety production, and improve work efficiency. and resource utilization, improved accuracy, reduced time and online computation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

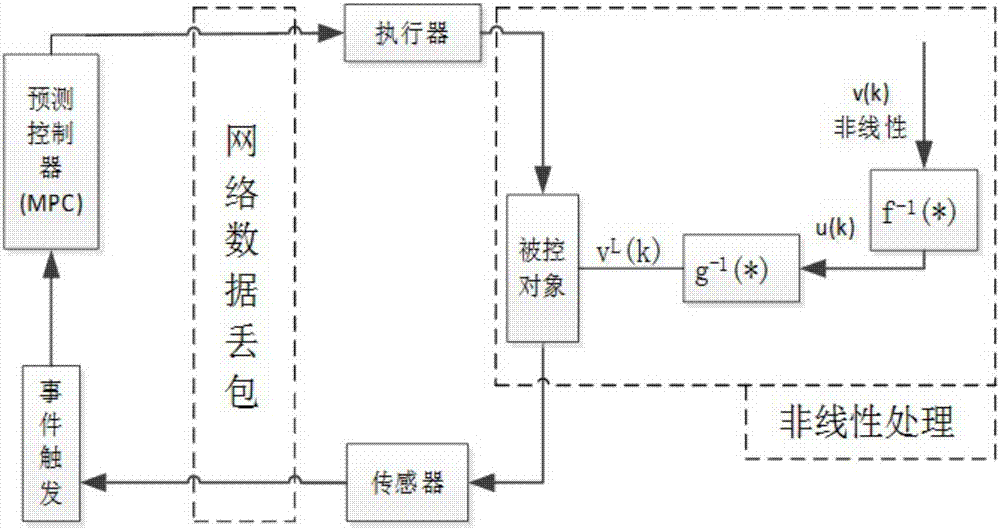

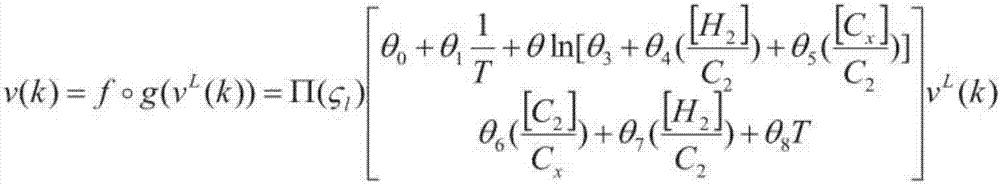

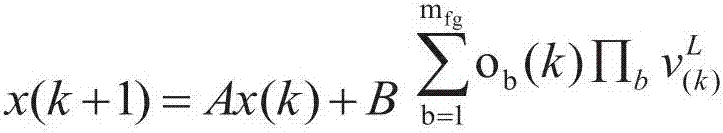

[0035] Such as figure 1 As shown, the predictive control system of the polyethylene quality index system includes a nonlinear processing module, an event trigger module and a network predictive control module. In the nonlinear processing module, firstly, the nonlinear input function of the polyethylene quality index system is taken as The inverse function, and adopts the method of multi-package description to approximately transform the nonlinear input in the polyethylene quality index system into a linear input; the event trigger module is used to send the trigger signal to the network predictive control module, if the event trigger module sends the signal to controller, the system executes the optimization calculation, otherwise it does not execute, so the event trigger module can not only greatly improve the resource utilization rate, bu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com