Solar cell, solar cell manufacturing method and electrical equipment

A technology of solar cells and manufacturing methods, which is applied to circuits, photovoltaic power generation, electrical components, etc., can solve the problems of increasing the manufacturing process and manufacturing cost of the surface anti-reflection layer, affecting the conversion efficiency of solar cells, and slow carrier separation speed, etc. Achieve the effect of reducing production process, improving practicability and improving utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

[0034] Aiming at the problems existing in the existing solar cells, the invention provides a solution.

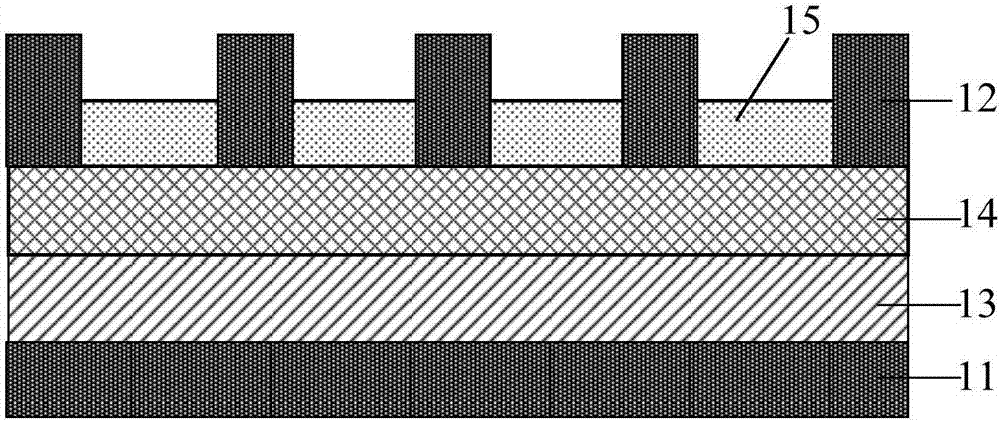

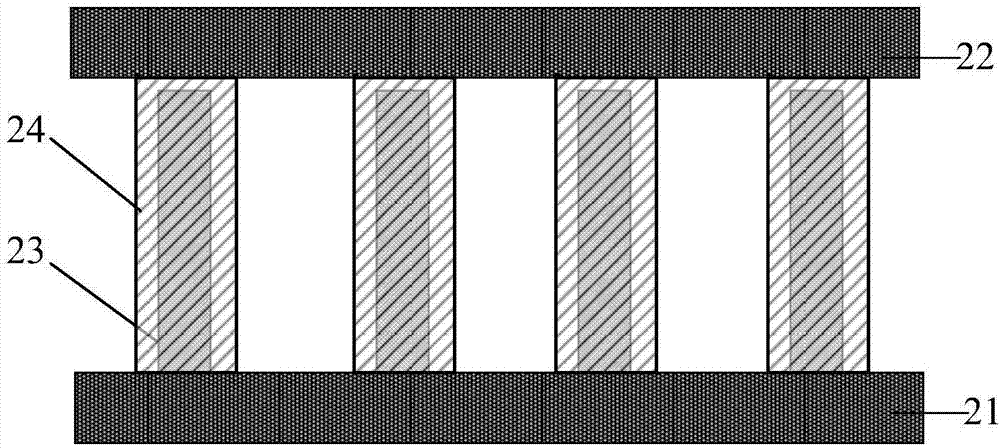

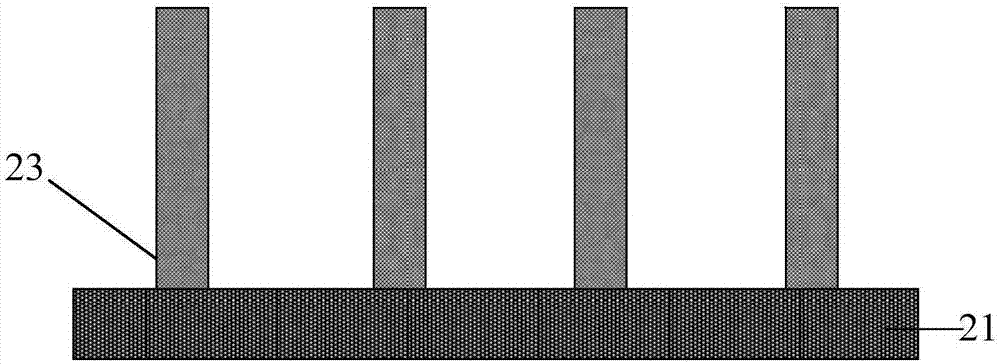

[0035] On the one hand, embodiments of the present invention provide a solar cell, such as figure 2 shown, including:

[0036] The first substrate 1 and the second substrate 2 arranged oppositely;

[0037] A plurality of PN junctions arranged between the first substrate 21 and the second substrate 22, each PN junction connects the first substrate 21 and the second substrate 22, and respectively includes: an inner core 23 as a P electrode, and an inner core 23 as an N electrode And cover the cladding layer 24 of the inner core 23 .

[0038] The PN junction of the solar cell of this embodiment is that the N electrode surrounds the P electrode. This ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com