Micro heat dissipator with gas-liquid separating function and fuel battery system

A gas-liquid separation and radiator technology, applied in fuel cells, fuel cell additives, fuel cell heat exchange, etc., can solve problems such as hindering the compression volume of portable fuel cell systems, limited optimization potential, etc., and improve the gas-liquid separation efficiency. , good heat exchange effect, the effect of reducing the pressure head

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

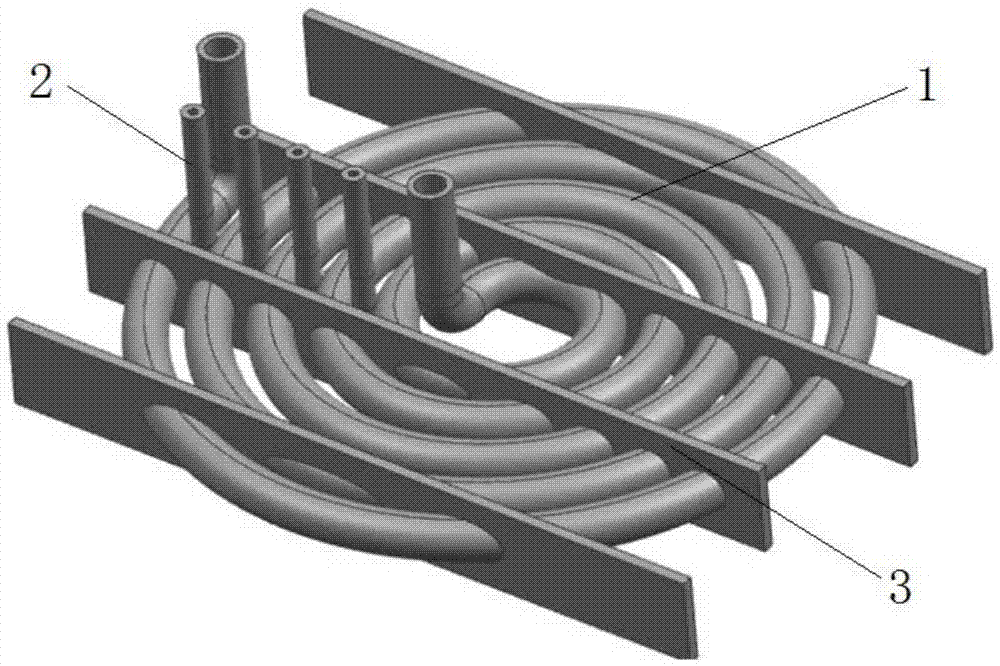

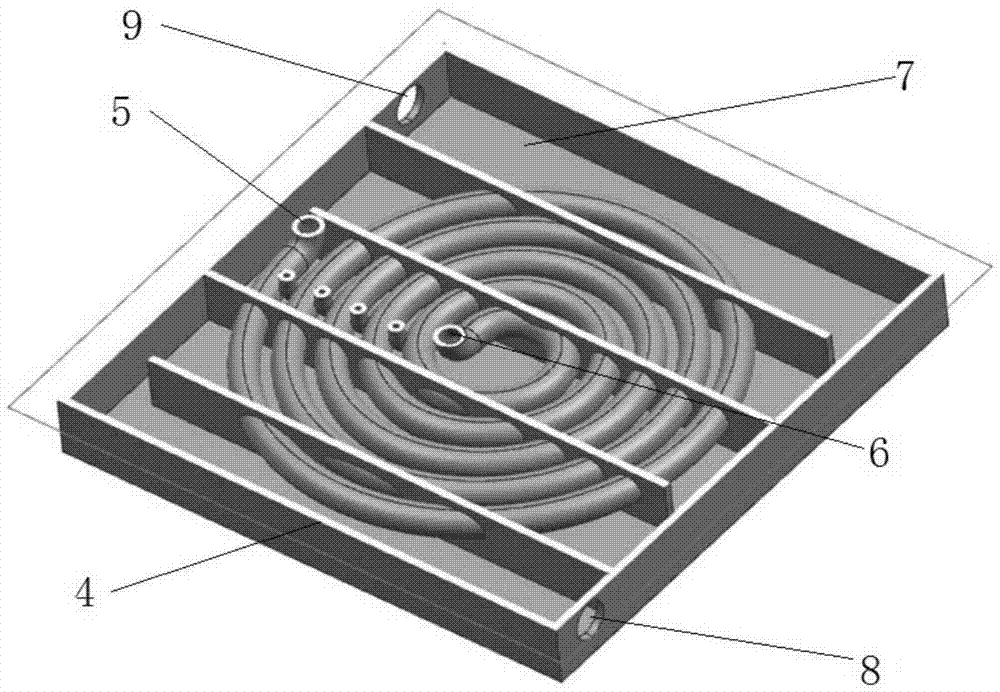

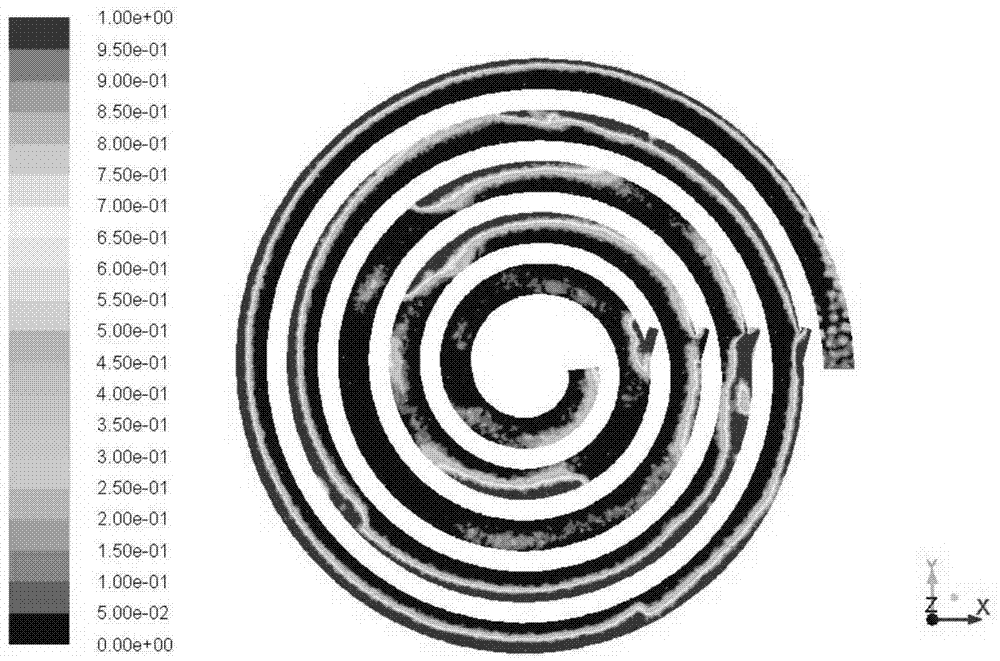

[0030] The mosquito-repellent coil 1, drainage pipe 2, baffle plate 3 and shell 4 of the radiator are all made of stainless steel and formed by 3D printing technology. The coil inlet 5 is the outermost ring pipe of the mosquito coil 1 extending perpendicular to the plane direction of the mosquito coil 1 through a 90-degree corner, and the coil outlet 5 is the innermost ring pipe of the mosquito coil 1 perpendicular to the mosquito coil through a 90-degree corner Coil 1 extends in the plane direction, with a wall thickness of 0.3mm and a diameter of 4mm. Mosquito coil 1 is set around 5 circles, and the outer diameter of the circle can be set to 50mm; drainage tube 2 is inserted into the outer wall of the coil along the tangential direction of the coil, and penetrates In the channel of the mosquito coil 1, and extend perpendicular to the plane of the mosquito coil 1 through a 90-degree corner, set up one per week, in a straight line with the inlet and outlet of the mosquito coil ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com