Cylindrical surface contact connection assembly

A connection component, cylindrical technology, which is applied in the field of cylindrical surface contact connection components, can solve problems such as poor contact, temperature rise, and poor user feel, and achieve the effects of stable insertion force, favorable deformation and shrinkage, and strong electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

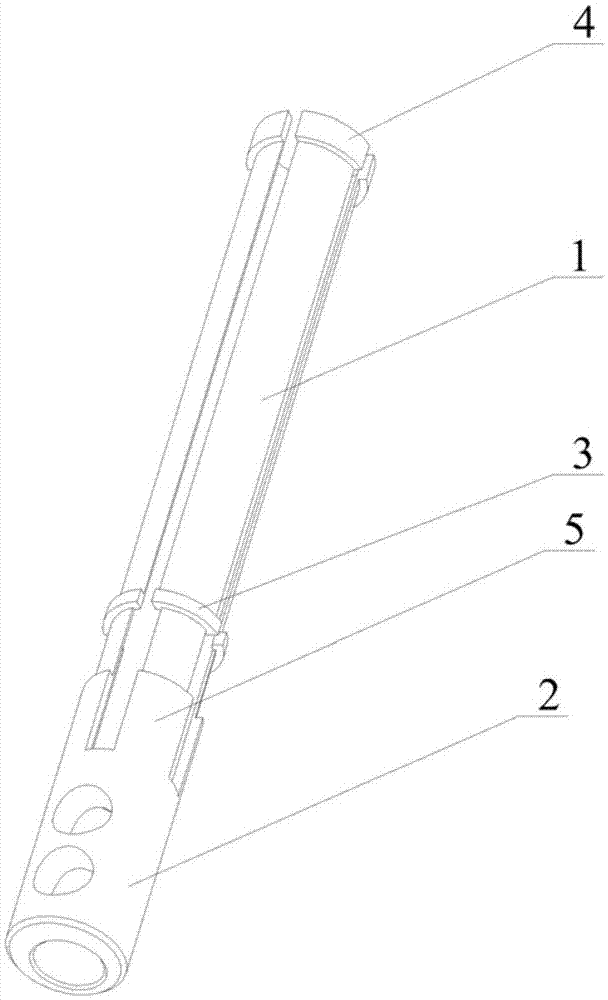

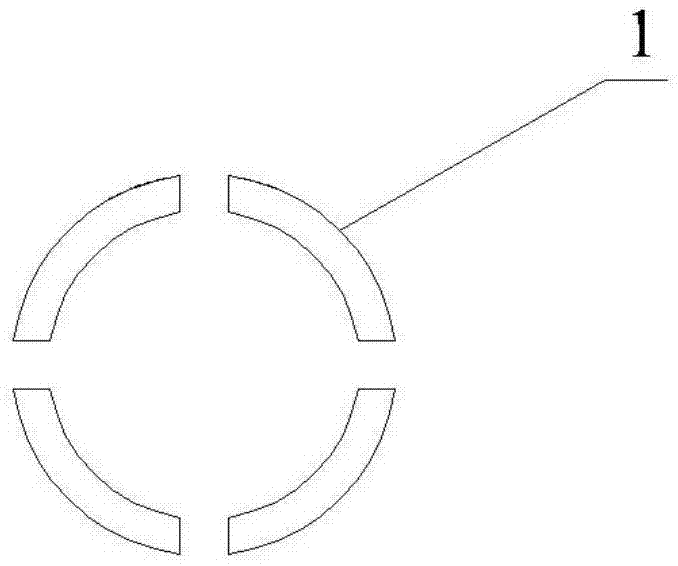

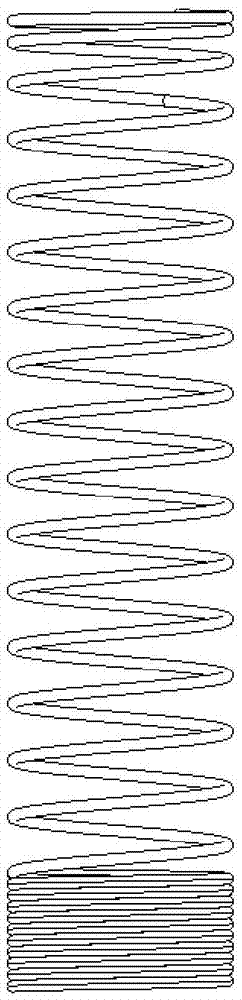

[0030] see figure 1 , the structure of the preferred embodiment of the present invention includes terminal 2, four arc-shaped contact pieces 1 and a new deformable arm 5, the length is about 0.5-2cm (centimeter), one end of the deformable arm is connected with the terminal, the other of the deformable arm One end is connected with four arc-shaped contact pieces, and a spring piece is arranged at the front end of the deformable arm. The contraction force of the spring piece makes the inner diameter of the front end of the deformable arm smaller than the outer diameter of the cylindrical plug. The outer diameter is tight fit, that is, the inner diameter of the slot part of the cylindrical socket is the same as the outer diameter of the cylindrical plug. The main function of the set coil spring or spring leaf is to shrink the deformed part. The inner diameter is equal to or smaller than the cylindrical plug. The contraction force includes deformation. The contraction force of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com