Stainless steel material welding polishing wiredrawing method and welding device used by stainless steel material welding polishing wiredrawing method

A technology for grinding and drawing and welding devices, applied in welding/welding/cutting items, auxiliary devices, welding equipment, etc., can solve the problems of insufficient welding surface quality of stainless steel materials, and achieve a small heat-affected range, avoid macula, and avoid damage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

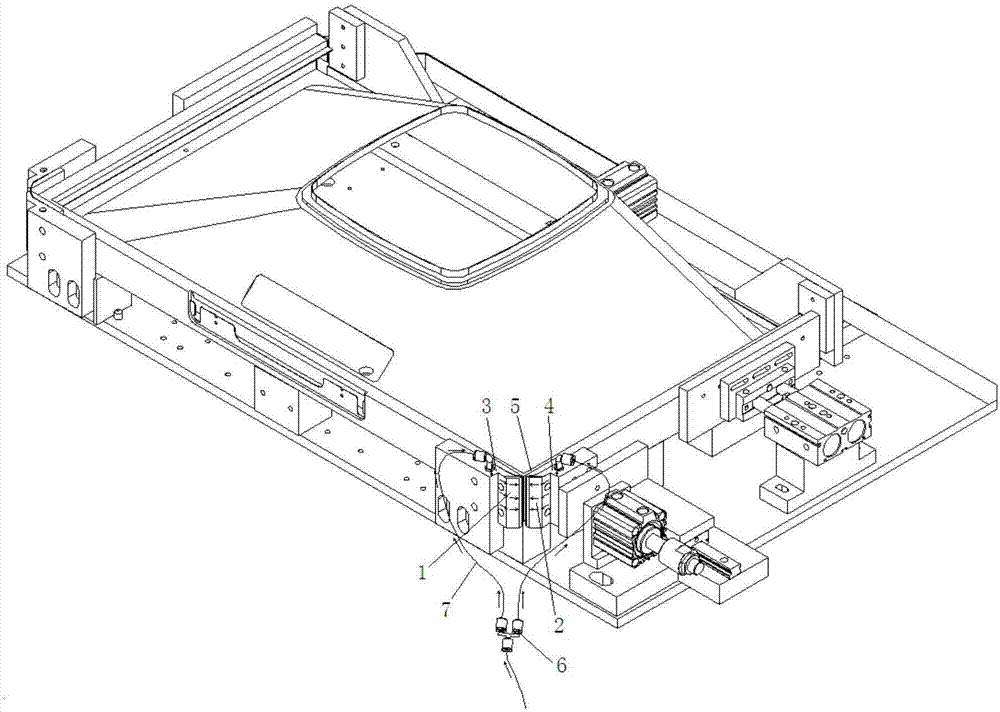

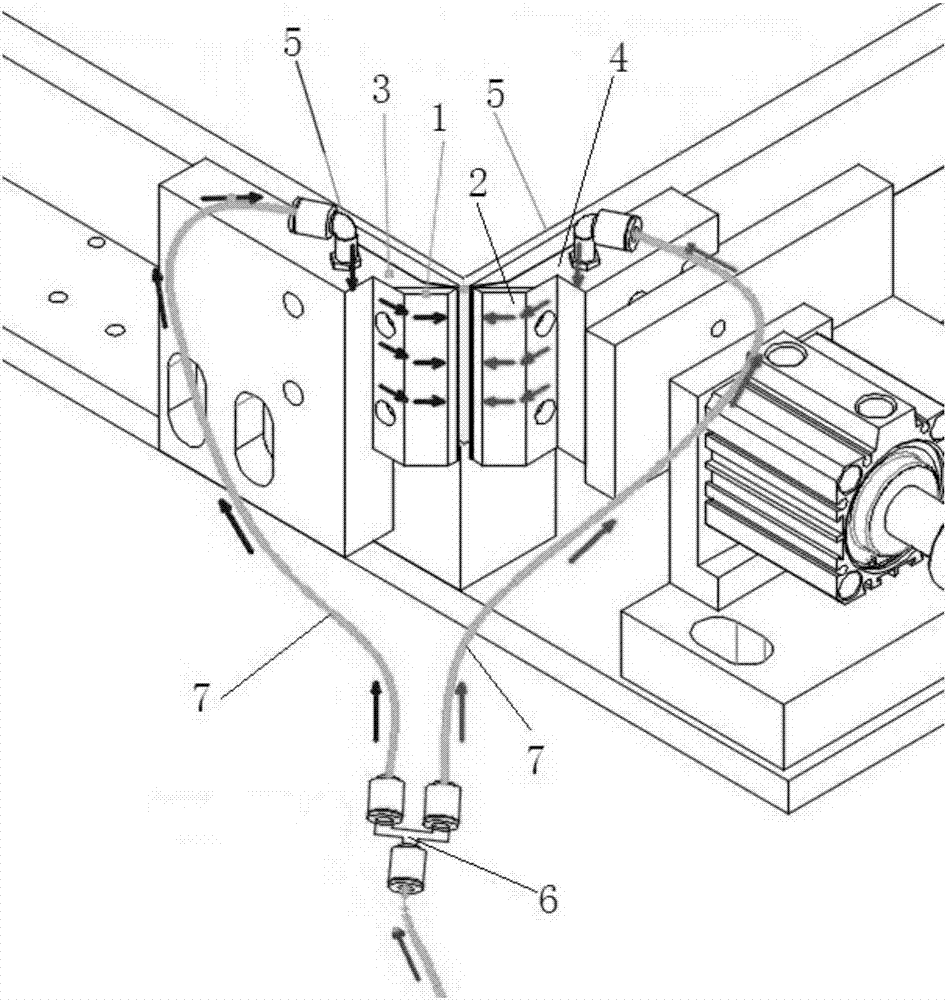

[0024] The present invention will be described in detail below in conjunction with accompanying drawing: Figures 1 to 4 As shown, the method includes a surface blowing protection method for stainless steel welding and a stainless steel grinding and wire drawing method. The stainless steel grinding and drawing method is based on the surface blowing protection method for stainless steel welding. The steps include:

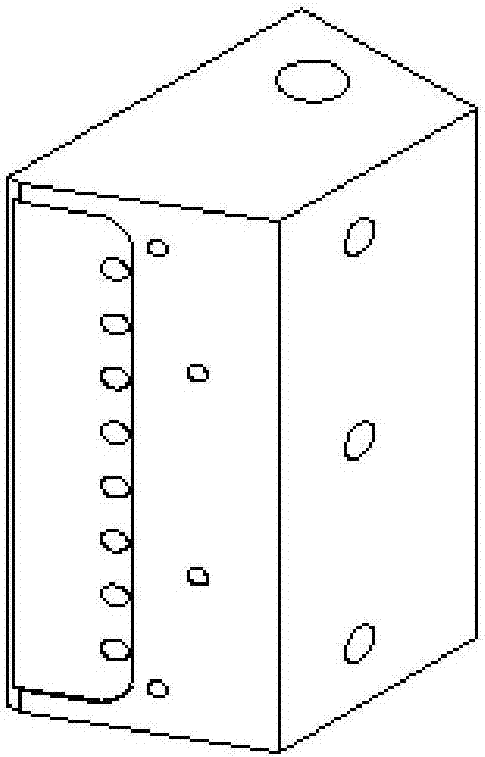

[0025] 1) Place the thin-plate stainless steel 5 to be welded on the welding frame, and the surface of the thin-plate stainless steel 5 to be welded is located between the left air guide block 1 and the right air guide block 2;

[0026] 2), the external inert gas passes through the diverter valve 6 along the pipeline, respectively passes through the left and right ventilation blocks and the left and right air guide blocks along the air pipe 7, and finally reaches the surface of the thin plate stainless steel 5 to be welded; during the welding process, the left and ri...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap