A device with functions of crystal structure detection and in-situ repair

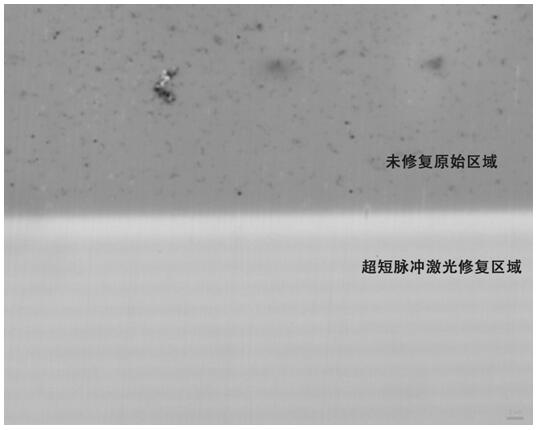

A technology of crystal structure and in-situ repair, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problem of uneven distribution of crystal defects on the surface of large-scale semiconductor thin film materials, and the difficulty of achieving precision on the surface of large-scale semiconductor thin film materials. problems such as positioning, inability to efficiently target and repair thin-film materials, etc., to achieve the effect of small heat-affected range, improved uniformity and crystal quality, and short action time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and embodiments. Obviously, the described embodiments are only a part of the present invention, rather than all embodiments. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without making creative efforts belong to the protection scope of the present invention.

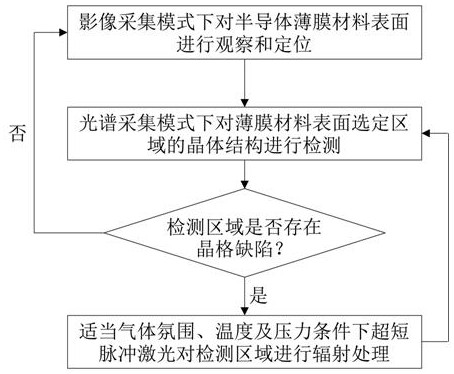

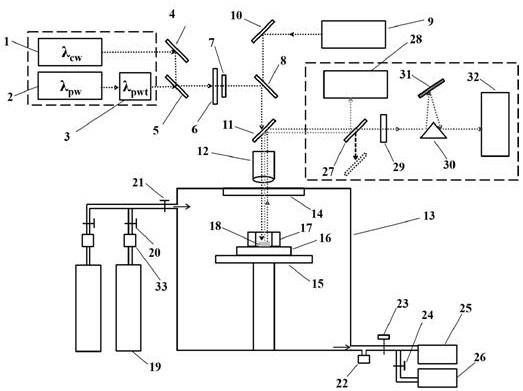

[0030] An embodiment of the present invention provides a device with the functions of crystal structure detection and in-situ repair. The device includes a laser source, a laser optical path system, an illumination light source, an illumination optical path system, an image and spectrum acquisition system, a vacuum system, an air path system, XYZ three-axis translation stage, hot and cold stage, diamond pressure chamber. Such as figure 2 , during the working process of the device, firstly, the image acquisition mode is used to observe and l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap