Three-dimensional printing system

A technology of three-dimensional printing and printed body, which is applied in the field of additive manufacturing, can solve the problems of reducing thermal current intensity, unstable current duration, small temperature difference, etc., and achieves simple machine system program programming, simple printing path planning, and mobile platform structure simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0177] The present invention will be described in detail below with reference to the preferred specific embodiments of the present invention and in conjunction with the accompanying drawings.

[0178] In the description of all the specific embodiments of the present invention, the orientation or positional relationship of the terms "upper", "lower", "left", "right", etc. is based on the orientation or positional relationship shown in the accompanying drawings, and is only for the convenience of description and to simplify operation, rather than indicating or implying that the device or element referred to must have, be constructed, and operate in a particular orientation.

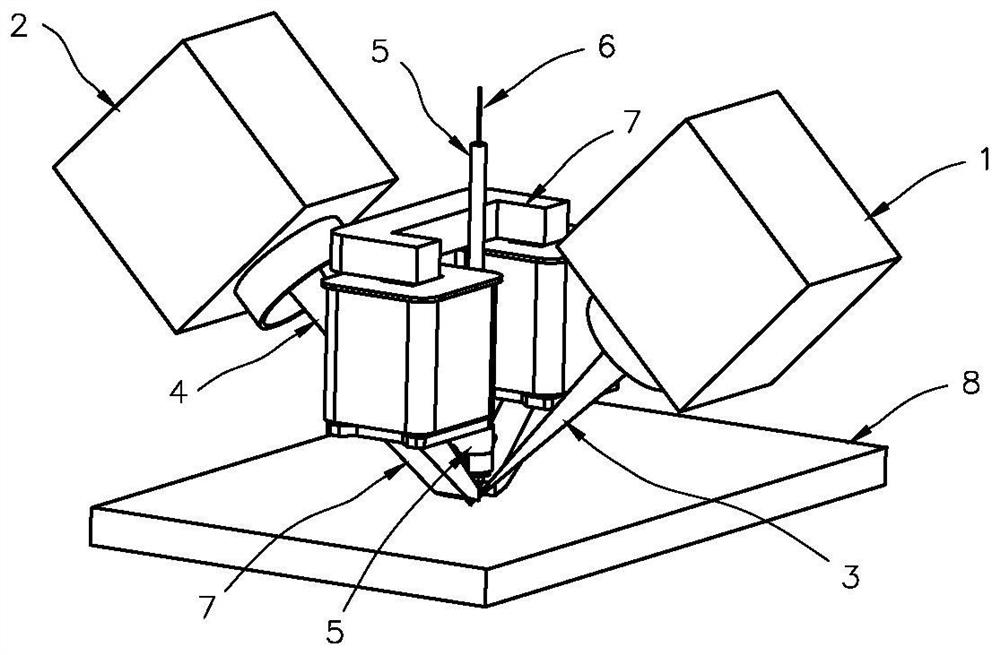

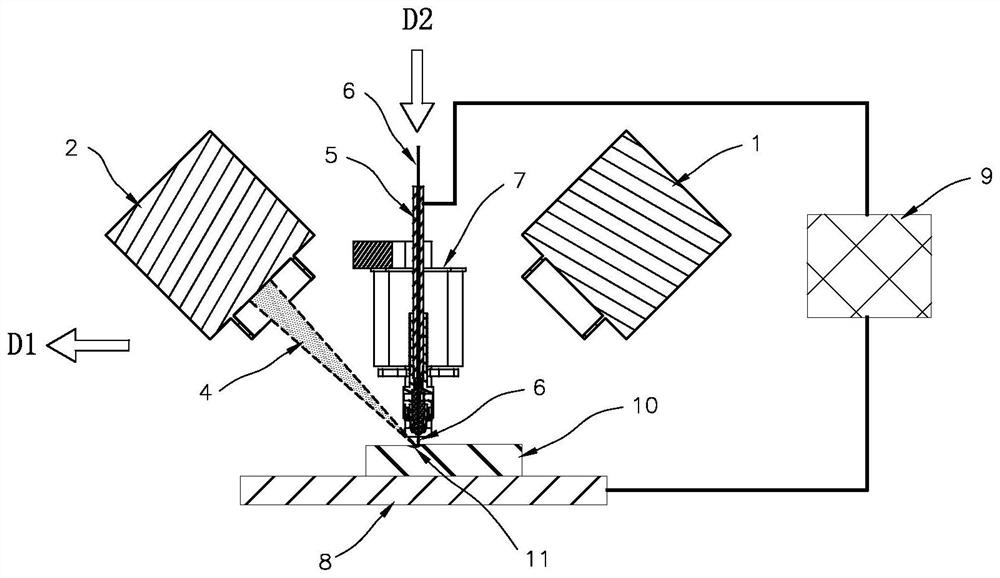

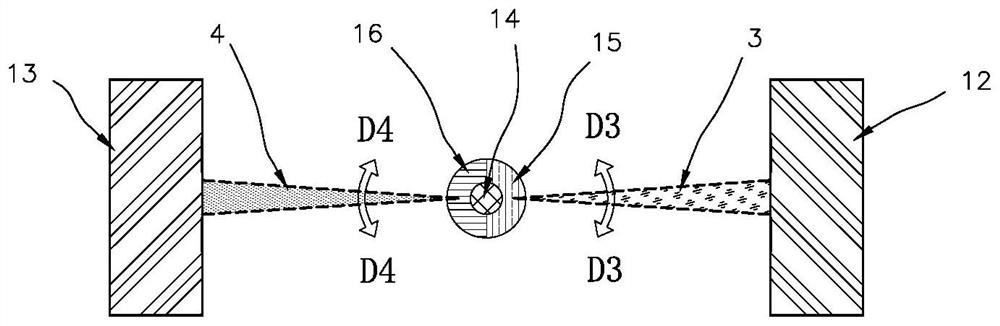

[0179] like Figure 1 to Figure 3 The principle of the first specific embodiment of a three-dimensional printing system of the present invention is shown: a moving platform (not shown in the drawings), a laser (not shown in the drawings), an optical path, and a solid-state material conveying mechanism are p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap