Adaptive multi-terrain cylinder amplitude-modulated motor vehicle wheel

An amplitude modulation and self-adaptive technology, applied in the direction of wheels, highly elastic wheels, vehicle components, etc., can solve the problems of limited obstacle-crossing ability, additional devices, inability to overcome climbing and slippery muddy ground, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] specific implementation plan

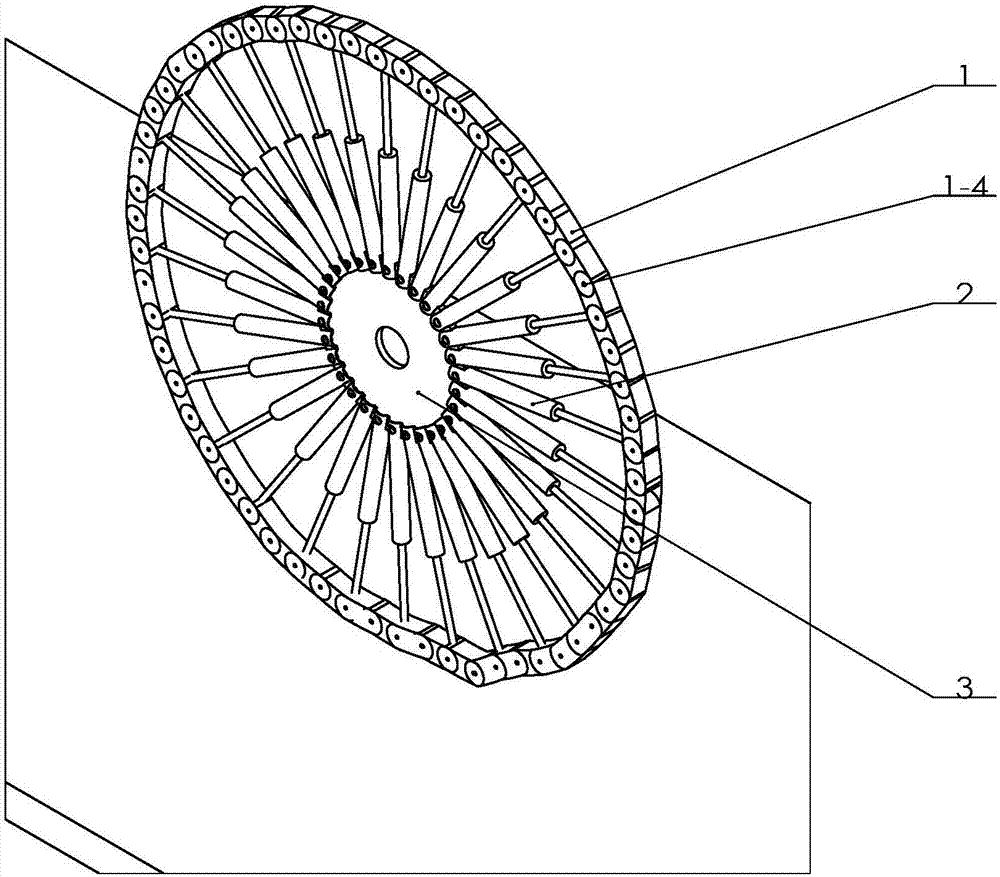

[0019] The specific implementation technical scheme of the described rim part of the wheel of the present invention is, see image 3 , Figure 4 : The outer surface of the rubber wheel surface block 1-1 is pressed with grooved anti-skid tread patterns, and the connecting ends at both ends are respectively set as male and female tooth-shaped interfaces, and the lower two ends of the rubber wheel surface block 1-1 are provided with dovetail-shaped protrusions. It is connected and fixed on two fixed metal base pieces 1-2 with the same dovetail slot, and then the two limit metal pieces 1-3 are used to limit and fix the positions of the inner and outer sides to form a rubber wheel surface block assembly assembly. This assembly is convenient. Routine maintenance and replacement, the assembly assembly composed of multiple sets of end-to-end rubber wheel surface blocks is hinged and connected to each other through pin sleeves 1-4, and rivets 1-5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com